To Clean or Replace Inlet Filter

WARNING: Unplug cord from electrical outlet

before servicing.

1. Remove the dust bag.

2. Snap the filter retainer from

its fitting

(fig 10).

3.

Remove the filter and clean

by shaking or vacuuming.

Replace the filter if worn or

not cleanable.

4. Replace filter in the retainer

and snap into place.

5. Replace dust bag.

CAUTION: Do not operate the

vacuum without the inlet filter in

place.

To Replace Brush

WARNING: Unplug cord from electrical outlet

before servicing.

1. Remove the screw holding

the brush access plate and

remove plate

(fig 11).

2. Grasp the brush strip and

slide it out of the brush

extension.

3. Replace the strip with a new

one and slide it into place.

4. Replace the access plate

and install the screw.

If a previous adjustment has

already been made and bristle

height does not extend above

baseplate, a new brush

assembly should be ordered.

6

General Information

The performance of your new vacuum cleaner greatly depends upon

care and maintenance. The instructions in this manual will guide you

in performing basic care and maintenance. To obtain the most satisfying

years of service read the instructions and keep them handy for future

reference.

Disposable Paper Filter Dust Bags

Disposable paper filter dust bags play a very important role in the

efficiency of your ORECK vacuum cleaner. The purpose of the paper

bag is to trap dirt, but at the same time it must be porous enough to

allow air to pass through. If the paper bag becomes clogged, no air

can pass through the cleaner and cleaning cannot take place,

regardless of the cleaner’s power. Increase the CLEANING POWER

of your vacuum cleaner by changing the bag often.

T

o keep your cleaner operating at maximum efficiency, change the

dust bag frequently.

DO NOT OVER FILL DUST BAG.

Be sure the disposable paper filter dust bag is installed properly.

All paper dust bags are not the same. Your ORECK recommend-

ed disposable dust bags have been designed to be used with the

ORECK vacuum

cleaner. Using bags other than ORECK

recommended disposable bags will affect the cleaning ability

of your cleaner and could cause damage to it.

Lubrication

The vacuum cleaner motor bearings are factory lubricated and

sealed. Further lubrication is not required.

General Vacuum Cleaner Care

At least once a month, check for and remove excessive lint, string or

hair from revolving brush.

Wipe the outside of the vacuum cleaner with a damp cloth. Also clean

the base of cleaner and housing area.

A little preventative maintenance will keep your cleaner looking new

and will ensure continued cleaning effectiveness.

CAUTION—Wood Floors, Soft (Vinyl, Asphalt Tile, etc.) Floor

Surfaces and Polished Floor Finishes

Use floor and floor finish manufacturer’s recommended methods of

cleaning. The metal strip on the base of the vacuum cleaner could be

damaged if used on concrete or abrasive surfaces, and, therefore,

cause damage to wood floors, soft (vinyl, asphalt tile, etc.) floor

surfaces and polished floor finishes. The roller brush may also scuff

very soft finishes.

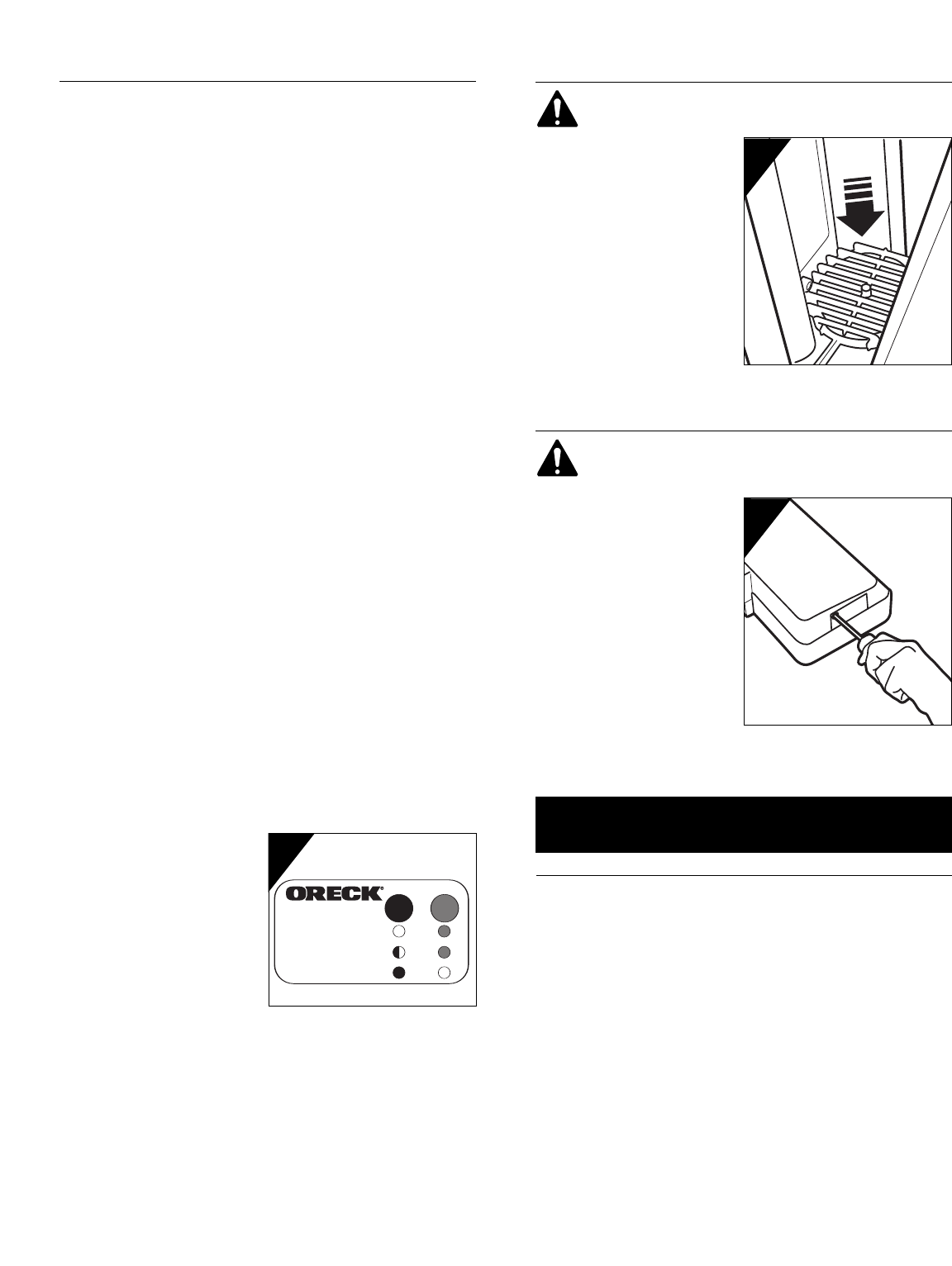

Electronic Brush Alert

The vacuum cleaner is equipped

with an electronic power brush

alert: two lights - GREEN and

RED

(fig 9).

Green Light - Lower brush

unit operating properly.

Green Light and

Blinking Red Light -

Brush

drive belt out or broken.

Red Light - Brush rotation

obstructed. Refer to

T

roubleshooting section.

These lights alert the operator of problems which must be corrected

immediately. Monitor these lights during operation.

Thermal Overload

The internal temperature of the vacuum motor is sensed at all times.

When the temperature gets too high the sensor shuts of

f the vacuum

motor. Inspect the machine for any air obstruction. The sensor will

reset automatically when the sensor and electric motor have cooled

suf

ficiently

.

The motor can then be restarted

.

OPERATION GUIDE

NORMAL OPERAT I ON

BELT BROKEN

RED BLINKING

BRUSH BLOCKED

AW-535

IVAC Operation Guide unit

9

10

11

Replacement Parts (Sold Separately)

ITEM PART #

1. Bag (10 pack) PK10PRO14DW

2. Belt (single) 40332-01

3.

Dusting Brush Nozzle

40333-01

4.

Fabric Brush Nozzle

40334-01

5.

Crevice Tool Nozzle 40335-01

6. Inlet Filter 40336-01

USA & Canada: 1-800-989-4244

FOR SERVICE CALL

USA & Canada: 1-800-989-4244