Date: ___________________________________________

Tag: _____________________Qty:___________________

Project: _________________________________________

Engineer: _______________________________________

Contractor: ______________________________________

Supplier: ________________________________________

Quote#:_________________________________________

Submitted by: ____________________________________

7

ENGINEERING DATA

THERMALLY CONDUCTIVE, PATENTED ALUMINUM CORE

The cross-flow heat recovery core transfers heat between the two

airstreams. It is easily removed for cleaning or service.

MOTORS AND BLOWERS

High effficiency electronic comutated ECM motor for maximum energy sav-

ings. Each air stream has one centrifugal blower. 5 speed fan operation

driven by one double shaft motor. 120 VAC, 1.0 Amps.

FILTERS

Washable air filters in exhaust and supply air streams.

MOUNTING THE HRV

Four threaded inserts at corners of case designed to accept four reinforced

polyester straps that are supplied with the unit.

DEFROST

Recirculating damper defrost system.

DEHUMIDISTAT

Adjustable Internal Dehumidistat.

CASE

Twenty gauge prepainted galvanized steel (G60) for superior corrosion resis-

tance. Insulated to prevent exterior condensation. Drain connections 2 -

1/2" (12 mm) OD.

CONTROLS

ControlAir 15 - Standby/ON mode, 20 ON/ 40 OFF mode, 20 ON/40

Recirculation mode, Recirculation mode (each mode has 5 speeds). Control

pad can be removed from HRV and remotely mounted.

Weight 71 lbs. (32.5 kg) Shipping Weight 73 lbs. (33.5 kg)

BALANCING DAMPER

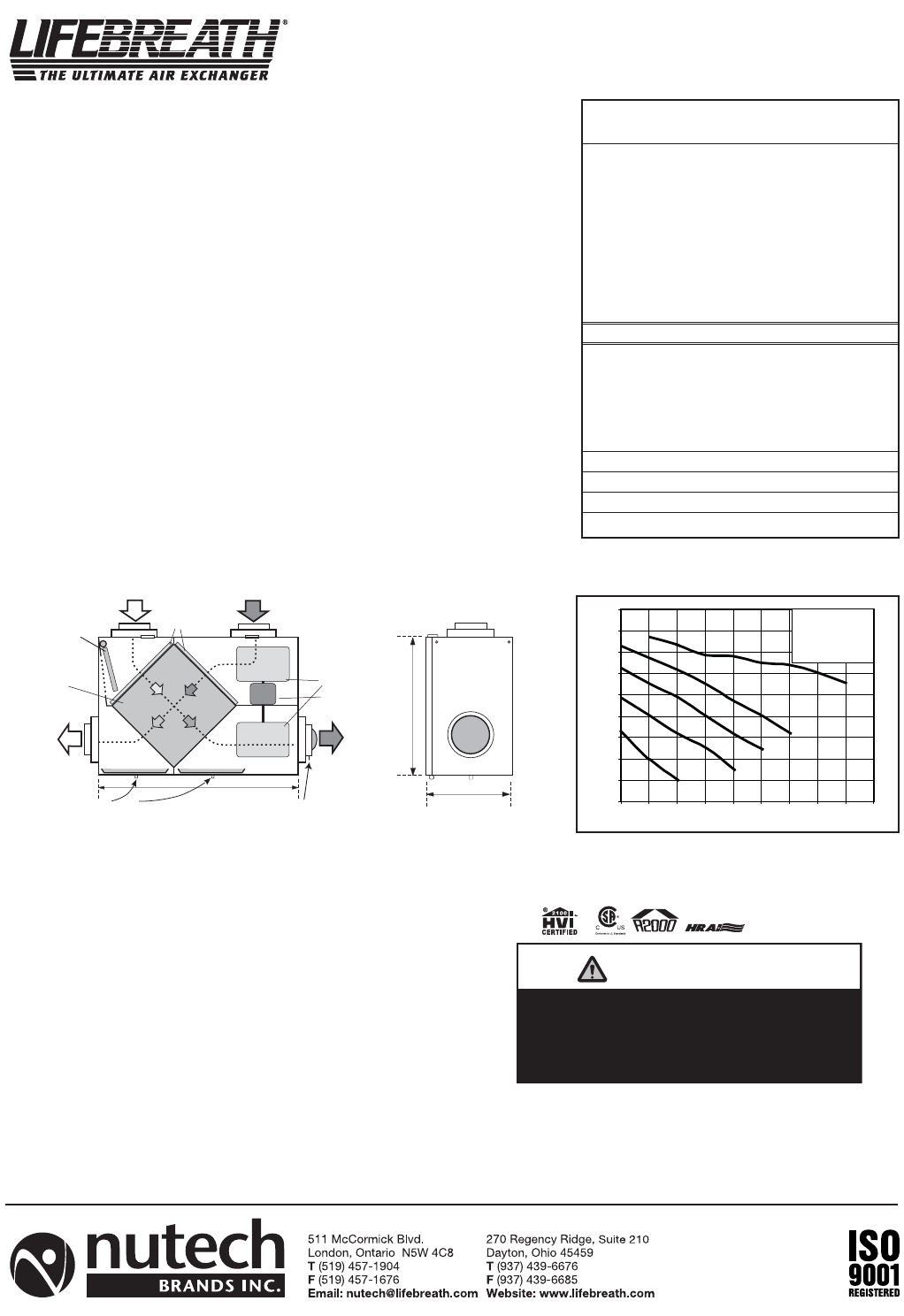

33 5/8"

(850mm)

STALE AIR

FROM INSIDE

FRESH AIR

FROM OUTSIDE

STALE AIR

TO OUTSIDE

FRESH AIR

TO INSIDE

14 3/4"

(375)

19"

(483)

*All Duct Connections 6" (150mm)

CONDENSATE DRAINS

FILTERS

BLOWERS

*NOTE: Front clearance of 25 inches (635 mm)

is recommended for servicing unit.

RECIRCULATING

DEFROST

DAMPER

MOTOR

CORE

OPTIONS

99-104 Digital Electronic Timer - 20/40/60 min.

99-109 Air Sentry™ Air Quality Monitor designed to accept

remotely mounted Control Pad

99-250 Ventilation Dehumidistat - Dehumidistat designed to

accept remotely mounted Control Pad.

99-163 Duct Heater w/ Electronic SCR Thermostat, 1 Kw, 6”

(150 mm)

99-164 Duct Heater w/ Electronic SCR Thermostat, 2 Kw, 6”

(150 mm)

99-186 Weatherhoods, Two - 6” (150 mm) c/w 1/4” (6 mm) mesh

screen

99-SILENCER6 6” dia. 16” long

WARRANTY

Units carry a LIFETIME warranty on the heat recovery core and

a 5 year replacement parts warranty.

DIMENSIONS 155ECM inches (mm)

Model 155ECM

Allunits conformto CSA

andUL standards.

The ECM motor produces a tone that some may

find objectionable. We recommend the

installation of the optional 99-SILENCER6 on the

‘Stale Air from Inside’ and ‘Fresh Air to Inside’

ducts.

ATTENTION

*SensibleEfficiency –thermal **LatentEfficiency –moisture

Note: Effectiveness - based on temp. differential between the 2 airstreams

Efficiency – takes into account all power inputs

Performance (HVI certified)

Netsupply airflow incfm (L/s)against externalstatic pressure

E.S.P

(external static pressure) [cfm (L/s)]

@ 0.1" (25 Pa) 164 (77)

@ 0.2" (50 Pa) 157 (74)

@ 0.3" (75 Pa) 147 (69)

@ 0.4" (100 Pa) 146 (69)

@ 0.5" (125 Pa) 140 (66)

@ 0.6" (150 Pa) 138 (65)

@ 0.7" (175 Pa) 131 (62)

@ 0.8" (200 Pa) 121 (57)

Max. Temperature Recovery 79%

Sensible Effectiveness

@ 66 cfm (31 L/s) 32°F (0°C) 72%

*Sensible Efficiency

@ 66 cfm (31 L/s) 32°F (0°C) 66%

*Sensible Efficiency

@ 66 cfm (31 L/s) -13°F (-25°C) 67%

VAC @ 60HZ 120

WATTS / Low speed. 17

WATTS / High speed 95

Amp rating 1.4

5

1

2

3

4

10

30

50

70

90

110

130

150

170

190

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9

Static Pressure (in w.g.)

Air Flow (cfm)

5 - High Speed

*4 - Medium High Speed

*3 - Medium Speed

*2 - Medium Low Speed

*1 - Low speed

* Manufacturers Data