16

Operating the ControlAir 15

Plugging in the HRV/ERV energizes the unit. A self

test function will be performed every time the

HRV/ERV is energized (refer to “Self Test” for more

details). After the self test has completed successfully

the HRV/ERV will default to Speed 1. This is the facto-

ry default setting. Follow the instructions found on the

HRV/ERV door to select desired mode and speed, or

refer to the instructions found on the following page.

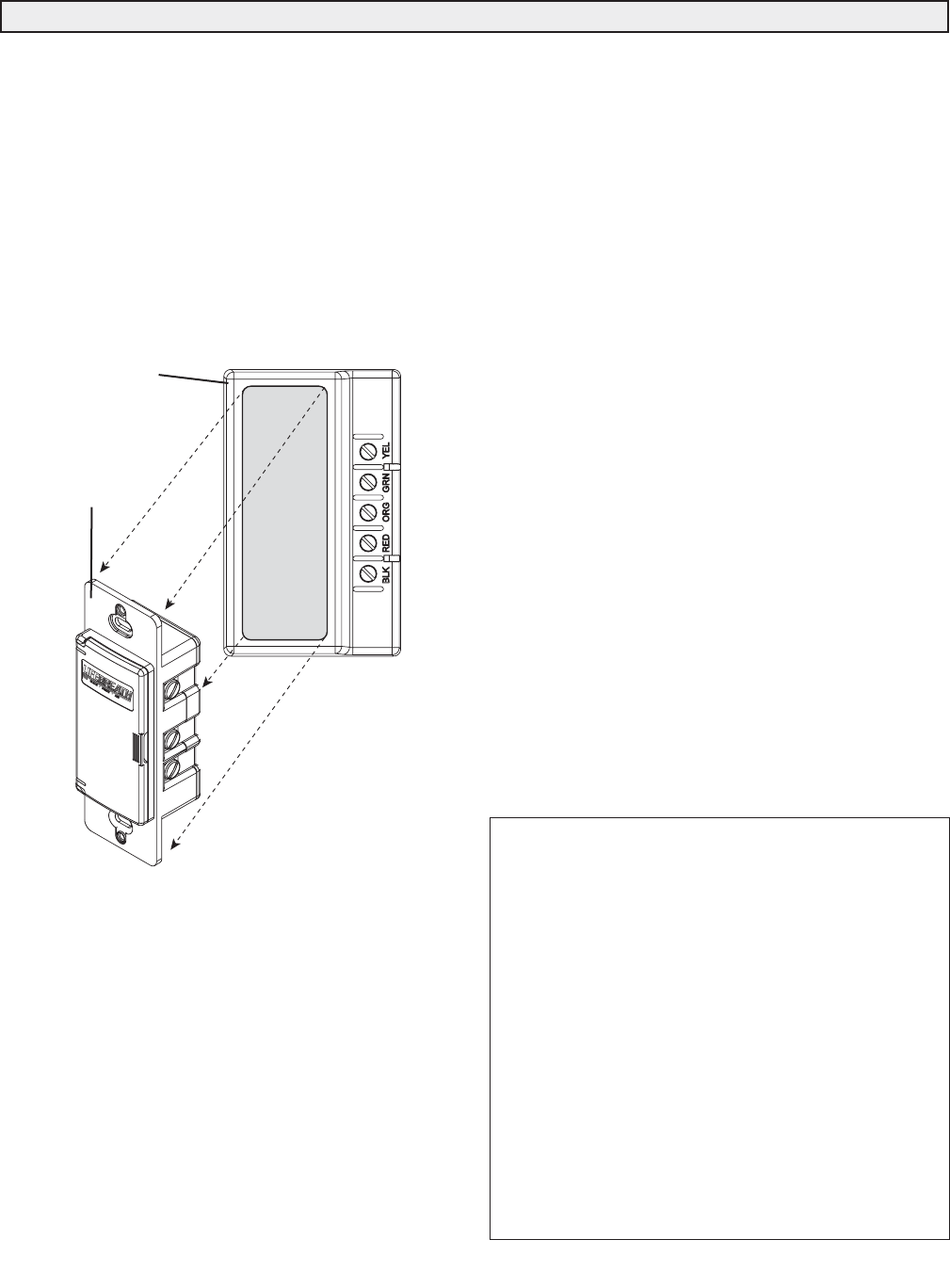

Removing and relocating the Control Pad

The Control Pad can be removed and installed in a

remote location (100’ wire length max). The Control

Pad can be installed in a 2x4 box with a “Decora” type

cover plate or can be installed in the optional

“Ventilation Dehumidistat” or “Air Sentry”. When the

Control Pad is installed in a remote location, all option-

al controls will still be wired to the Control Module on

the HRV/ERV. When remotely mounted on its own,

the Control Pad is wired to the Control Module by 3

wire (min. 20 gauge). Connect the colour coded termi-

nals to the corresponding terminals on the Control

Module. When the Control Pad is remotely mounted in

the Ventilation Dehumidistat or Air Sentry, refer to

optional controls page for wiring requirements.

Self Test

Each time the

HRV/ERV

is powered/energized the self

test function will automatically initiate. During the self test

the

HRV/ERV

will cycle through all the speeds

available (1-5), test the damper motor operation and

will default back to the previous mode/speed selection,

(factory default is Speed 1). Total self test duration is

approximately 1 min. 30 sec.

Automatic Defrost Operation

(Not on all models)

The advanced technology of the digital microprocessor

automatically activates the defrost system only as it is

needed. To be an efficient heat recovery device, the

HRV/ERV must effectively provide for core defrost as well

as providing efficient heat exchange. As outdoor

conditions cool, the temperature sensor (thermistor)

tracks the supply air temperature. The thermistor then

sends its signal to the microprocessor (circuit board)

which initiates only the defrost cycle time required to

clear the core. On recirculating defrost models, the

core is defrosted when the supply air port is automati-

cally blocked off and exhaust air is redirected back

through the HRV/ERV. On damper defrost models, the

core is defrosted when the supply air port is automati-

cally blocked off and the warm air surrounding the

HRV/ERV is drawn in through the defrost port. The

mode indicator will flash RED during the defrost cycle.

By optimizing the defrost cycle, the HRV/ERV com-

bines money saving performance with a well designed

and reliable control system.

Glossary

DEFROST MODE - to ensure reliable operation during cold

weather, the HRV/ERV will automatically cycle through its defrost

mode as needed. (not on all models)

DEHUMIDISTAT - a control device that senses the amount of

moisture in the air and will activate high speed fan operation

when the air moisture level exceeds the control setting. The opti-

mum air moisture level (or relative humidity [Rh]) in the typical

home is in the range of 30 to 50% Rh.

RESET - whenever resetting of the HRV/ERV is required, simply

disconnect power for 30 seconds.

STANDBY MODE - the HRV/ERV is energized and waiting for

fan operation to be initiated by a remote device or manual over-

ride.

THERMISTOR

- the

HRV/ERV

's temperature sensor which

measures electrical resistance in a known manner, as out-

door temperatures fluctuate.

ControlAir 15

Exploded view

Control Module

Control Pad

Function and Controls