23

A well designed and installed ducting system will allow

theHRV/ERV to operate at its maximum efficiency.

Always try to keep duct runs as short and straight as

possible.See Installation Diagrams for various instal-

lation options.

Outside Weatherhoods

The fixed covered hoods have a built-in bird screen

with a 1/4" (6 mm) mesh to prevent foreign objects

from entering the ductwork.

Locating the Intake Weatherhood

• Should be located upstream (if there are prevail-

ing winds) from the exhaust outlet

• At least 6' (2 m) from the exhaust weatherhood

• At least 6' (2 m) away from dryer vents and fur-

nace exhaust (medium or high efficiency

furnaces)

• A minimum of at least 6' (2 m) from driveways, oil

fill pipes, gas meters, or garbage containers

• At least 18" (457 mm) above the ground, or

above the depth of expected snow accumulation

• At least 3' (1 m) from the corner of the building

• Do not locate in a garage, attic or crawl space

Locating the Exhaust Weatherhood

• At least 6' (2 m) from the ventilation air intake

• At least 18" (457 mm) above ground or above the

depth of expected snow accumulation

• At least 3' (1 m) away from the corner of the

building

• Not near a gas meter, electric meter or a walkway

where fog or ice could create a hazard

• Not into a garage, workshop or other unheated

space

When installing the weatherhood, its outside perimeter

must be sealed with exterior caulking.

Installing the ducting from the

weatherhoods to the HRV/ERV

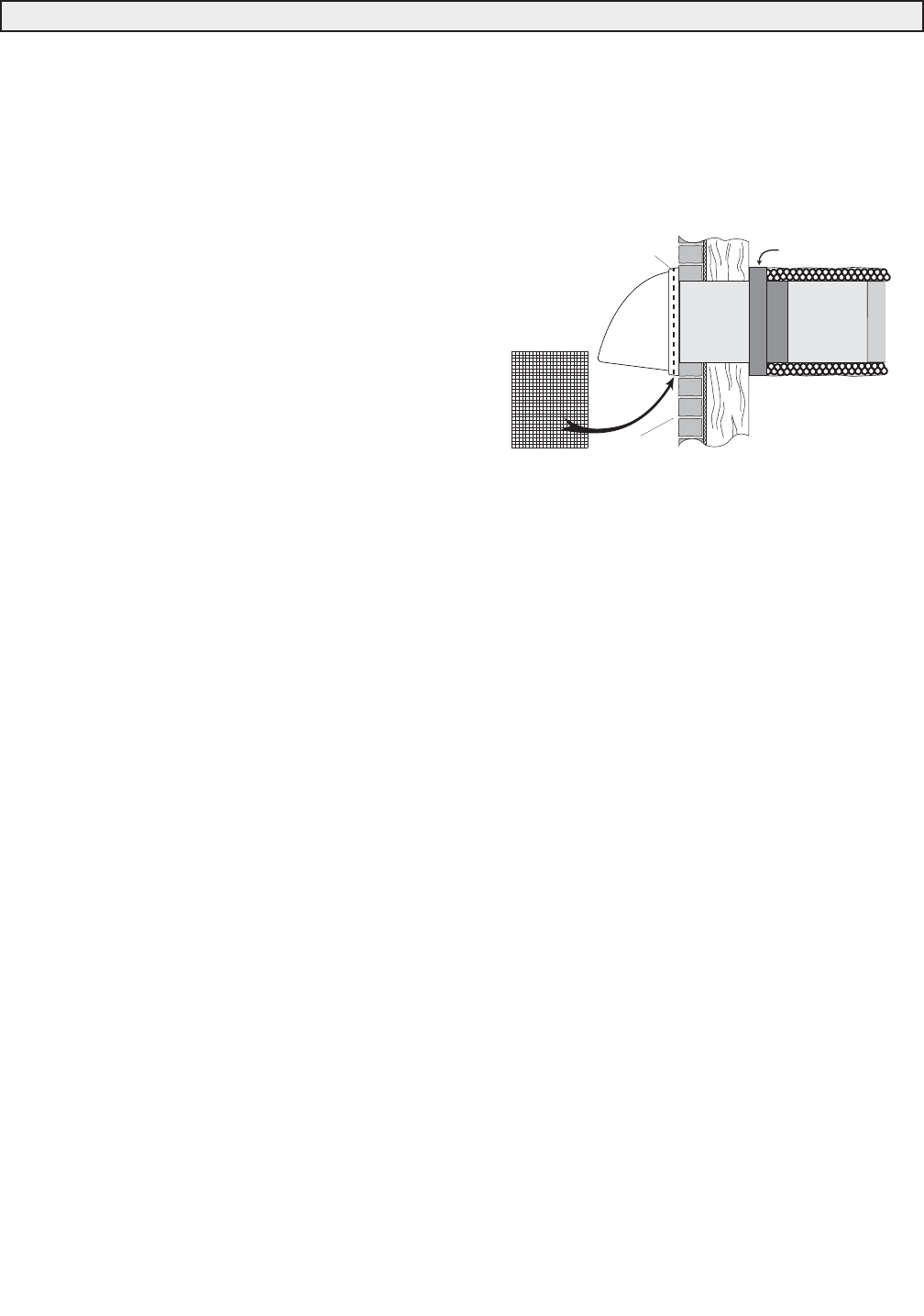

The inner and outer liners of the flexible insulated duct

must be clamped to the sleeve of the weatherhoods

(as close to the outside as possible) and the appropri-

ate port on the HRV/ERV. It is very important that the

fresh air intake line be given special attention to make

sure it is well sealed. A good bead of high quality

caulking (preferably acoustical sealant) will seal the

inner flexible duct to both the HRV/ERV port and the

weatherhood prior to clamping.

To minimize air flow restriction, the flexible insulated

duct that connects the two outside weatherhoods to

the HRV/ERV should be stretched tightly and be as

short as possible.

Twisting or folding the duct will severely restrict air

flow. See below for the recommended connection of

flexible insulated ducts to the the outside weather-

hoods and the HRV/ERV.

Warmside Ducting

To maximize airflow in the ductwork system, all ducts

should be kept short and have as few bends or elbows

as possible. Forty-five degree elbows are preferred to

90° elbows. Use “Y” tees instead of 90° elbows when-

ever possible.

All duct joints must be fastened with screws, rivets or

duct sealant and wrapped with a quality duct tape to

prevent leakage. We recommend aluminum foil duct

tape.Galvanized ducting from the HRV/ERV to the liv-

ing areas in the house is recommended whenever

possible, although flexible duct can be used in moder-

ation if necessary.To avoid possible noise transfer

through the ductwork system, a short length (approxi-

mately 12 " or 300 mm) of non-metallic flexible

insulated duct should be connected between the

HRV/ERV and the supply/ exhaust ductwork system.

The main supply and return lines to/from the

HRV/ERV must be 6 inches (150 mm) minimum.

Branch lines to the individual rooms may be as small

as 4 inches (100 mm), but 5 inch (125 mm) lines are

preferred .

All ducts running through attics and unheated spaces

must be sealed and insulated to code.

1. ThermalCollarslidesovergalvanized

sleeveofWeatherhood.

2. FastenThermalCollartoBelt.

3. SlidetheInsulatedFlexibleDuctingover

theWeatherhood'sgalvanizedsleeveand

fastenittotheThermalCollar.

4. Hoodishingedtoallowforeasyaccess

forcleaningofbirdscreen.

WEATHERHOODINSTALLATION

1/4"(6mm)SCREEN

(frontview)

EXTERIOR

WALL

SCREEN

(sideview)

COLLARISSUPPLIEDTO

ENSUREVAPOURBARRIER

IS100%SEALEDTO

WALLPLATE

12"galvanized

pipesupplied

Installing Air Ducts