28

the cad cell is operational, replace the primary

control.

4. If the LED continues to fl ash at the interval

listed above, verify that the control is not in

restricted mode. If in restricted mode, reset it.

If not in restricted mode, replace the control.

5. If the (LED indicator for R7184 control; green

LED for 7505 control) stays off while the fl ame

is on, check the cad cell sighting for view of

the fl ame.

6. If the burner locks out, check the cad cell

resistance. (See Table 8)

7. If the burner stays running, the system is

operational.

8. If the (LED indicator for R7184 control; green

LED for 7505 control) is off, check the cad cell

assembly after disconnecting the line voltage.

Burner will not start and the LED indicator is

fl ashing at 2 seconds on, 2 seconds off for

R7184 (or the green LED is fl ashing for 7505).

• Hold the reset button down for 1 - 2 seconds.

If LED indicator continues to fl ash, wait for

60 - 70 seconds. If it still continues to fl ash,

replace the primary control.

• Honeywell R7184 control: To check cad cell

resistance, press and release the button during

the run mode, with the igniter off. The LED will

fl ash to indicate the cad cell resistance. For

proper burner operation, it is important that

the cad cell resistance is under 1600 Ohms.

For cad cell resistance, see Table 8.

• Beckett 7505 control: To check cad cell

resistance, unplug the cad cell leads (yellow

wires) from the control. Measure the resistance

with a meter in the conventional way (when a

fl ame is present). For proper burner operation,

it is important that the cad cell resistance is

under 1,600 Ohms.

Table 8. Cad Cell Resistance when

sensing fl ame

LED Flashes (Ohms) Cad Cell Resistance

1 0-400

2 400-800

3 800-1600

4 >1600

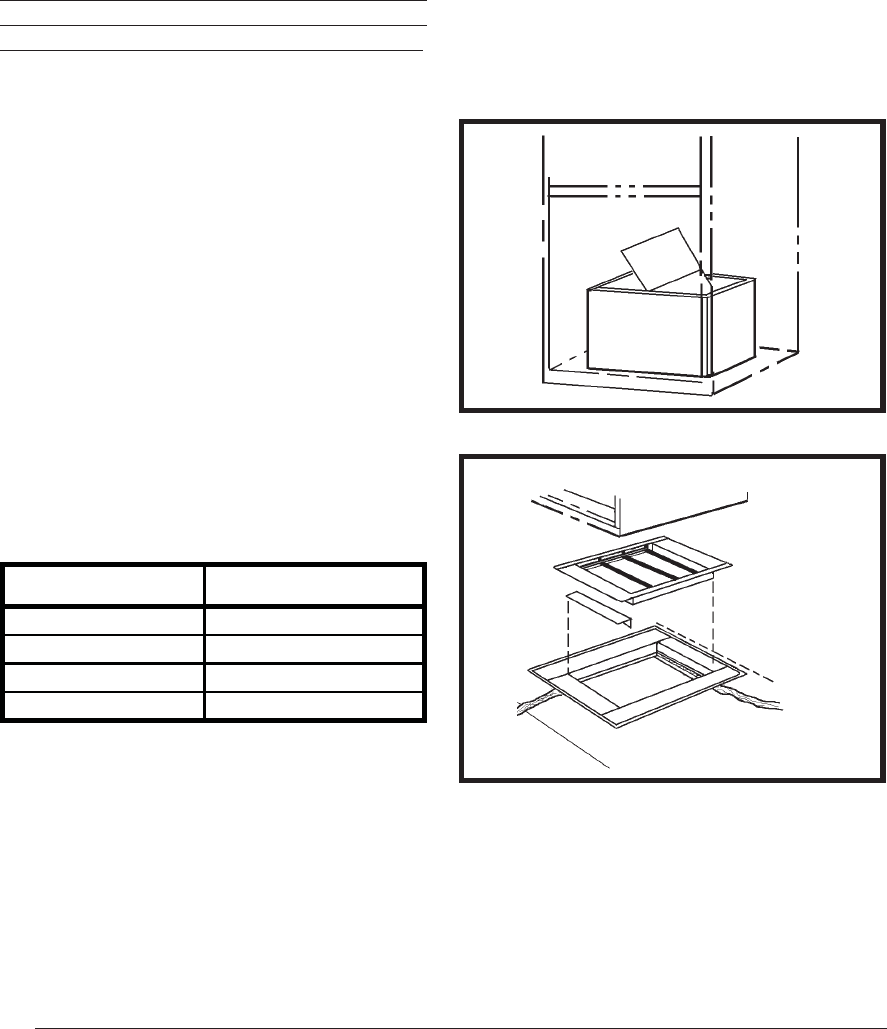

OPTIONAL ACCESSORIES

Necessary when the Furnace is Used with

Some Central Air Conditioners

If an air conditioner is installed that does not use

the furnace blower for air distribution and operates

independently of the furnace, the thermostat

system must have an interlock to prevent the

furnace and air conditioner from operating at

the same time. This interlock system usually

contains either a “Heat-Cool” switch which must

be turned to one of the positions to activate heat

or cool operation, or a positive “OFF” switch on

the cooling thermostat.

The furnace must also be equipped with an

automatic damper to prevent cold air from

being discharged up around the heat exchanger

(NORDYNE p/n 901996 for furnaces without coil

cavity, or p/n 901083 with coil cavity). See Figure

36 or 37. Cold air may cause condensation inside

the heat exchanger which can rust and lead to

early failure.

Figure 36. Coil Cavity Damper

Figure 37. Damper without Coil Cavity