16

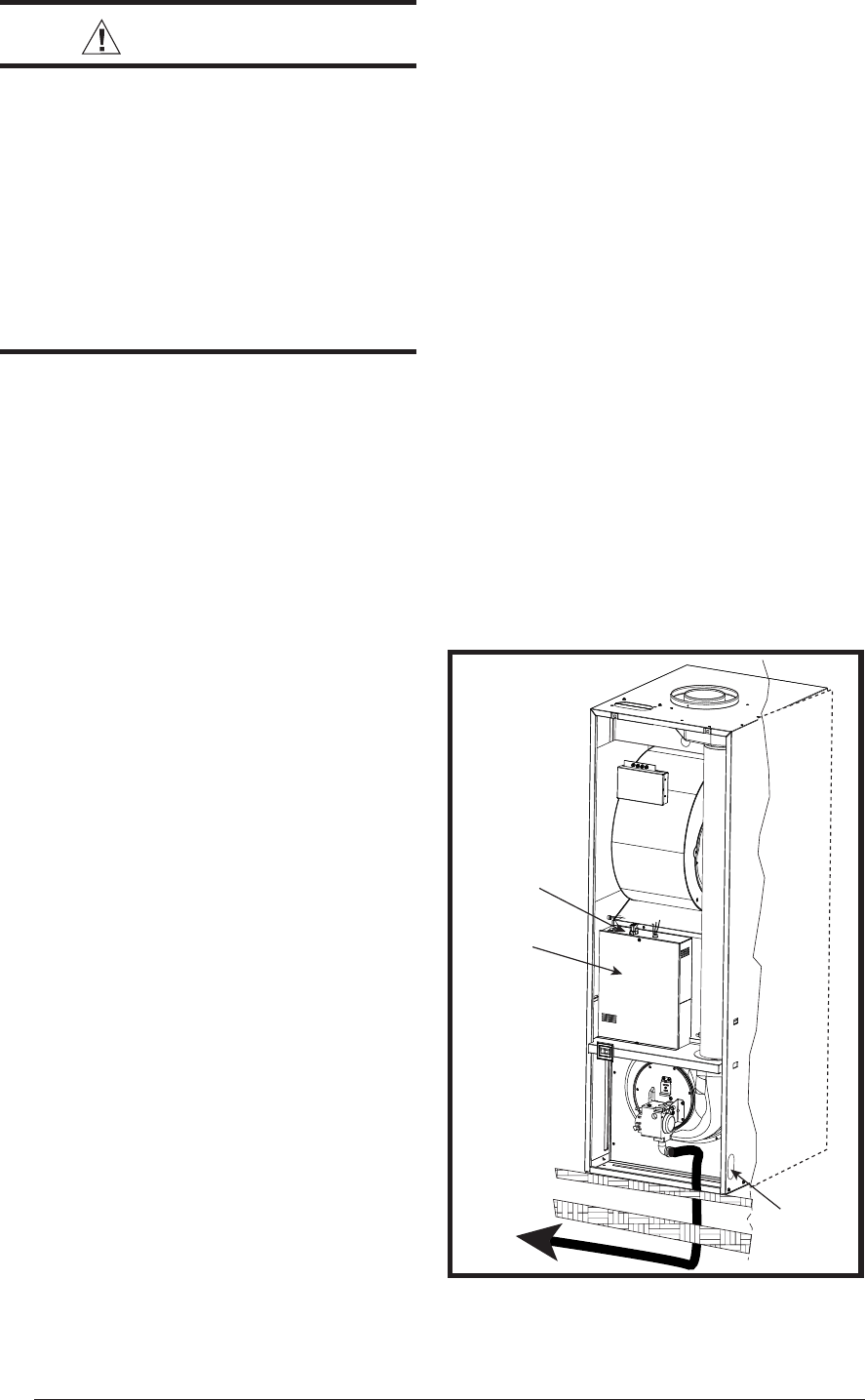

To Gas

Supply

Floor

Control

Panel

On-Off-Fan

Switch

Alt. Fuel

Line Entry

Floor Cavity

Figure 26. Typical Gas Piping

FUEL SUPPLY AND PIPING

WARNING:

All piping must conform with local

building codes, or in the absence

of local codes, with the most recent

edition of the National Fuel Gas

Code ANSI Z223.1 or (CAN/CGA

B149.1 or .2). Failure to follow all

safety warnings could result in

serious injury, death or property

damage.

This furnace may be installed with left or right

side gas entry. When connecting the gas supply,

provide clearance between the gas supply line

and the entry hole in the furnace casing to avoid

unwanted noise and/or damage to the furnace.

Typical gas service hookup for this furnace is

shown in Figure 26. Table 14 (page 37) lists

gas fl ow capacities for standard pipe sizes as a

function of length in typical applications based

on nominal pressure drop in the line.

IMPORTANT NOTES:

• Some local regulations require the

installation of a manual main shut-off

valve and ground joint union external to

the furnace (Figure 36). The shut-off valve

should be readily accessible for service

and/or emergency use. Consult the local

utility or gas supplier for additional

requirements regarding placement of the

manual main gas shut-off.

• Gas piping must never run in or through

air ducts, chimneys, gas vents, or elevator

shafts.

• Compounds used on threaded joints of gas

piping must be resistant to the actions of

-liquefi ed petroleum gases.

• The main gas valve and main power

disconnect to the furnace must be properly

labeled by the installer in case emergency

shutdown is required.

• Flexible gas connectors are not recom-

mended for this furnace but may be used

if allowed by local jurisdiction. Only new

fl exible connectors may be used. DO NOT

reuse old fl exible gas connectors.

• A drip leg should be installed in the vertical

pipe run to the unit (Figure 36).

• All piping shall be black iron pipe, or

equivalently sized steel tubing. Internally

tinned copper tubing may be used for gas

supply systems.

Fuel line installations other than typical

installations shown in Figures 26 and 27

(page 17) must comply with the fuel piping

provisions stated in the Federal Manufactured

Home Standard (H.U.D. TITLE 24, PART 280)

and the National Fuel Gas Code (ANSI-Z223.1/

NFPA-54).

• Optional fuel inlet lines are available for all

gas furnace models to permit the addition of

a 1/2” F.P.T. shut-off valve above the fl oor.

NOTE: Shut-off valve must be designed and

listed for use with liquid petroleum (L.P. gas).

The gas supply to your home will either be Natural

Gas or L.P. (bottle gas). Your furnace is factory

equipped to operate on Natural Gas. If your gas

supply is L.P. (bottle gas), you must contact a

qualifi ed serviceman or gas supplier to convert

the furnace. Instructions for gas conversion are

listed on page 18. Factory installed orifi ce sizes

are listed in Table 10 (page 31).

For natural gas operation, the furnace is designed

for 7” W.C. inlet pressure. Pressure is reduced

to 3 1/2” W.C. by the pressure regulator in the

gas valve. The maximum inlet pressure for the

valve is 13” W.C.