19

Figure 28. Honeywell Gas Valve

PRESSURE

REGULATOR

CAP

M11678

N

A

T

N

A

T

L

P

L

P

N

A

T

N

A

T

OR

OTHER SIDE

OF CAP

LP Gas

Configuration

Black Cover

Red

Natural Gas

Configuration

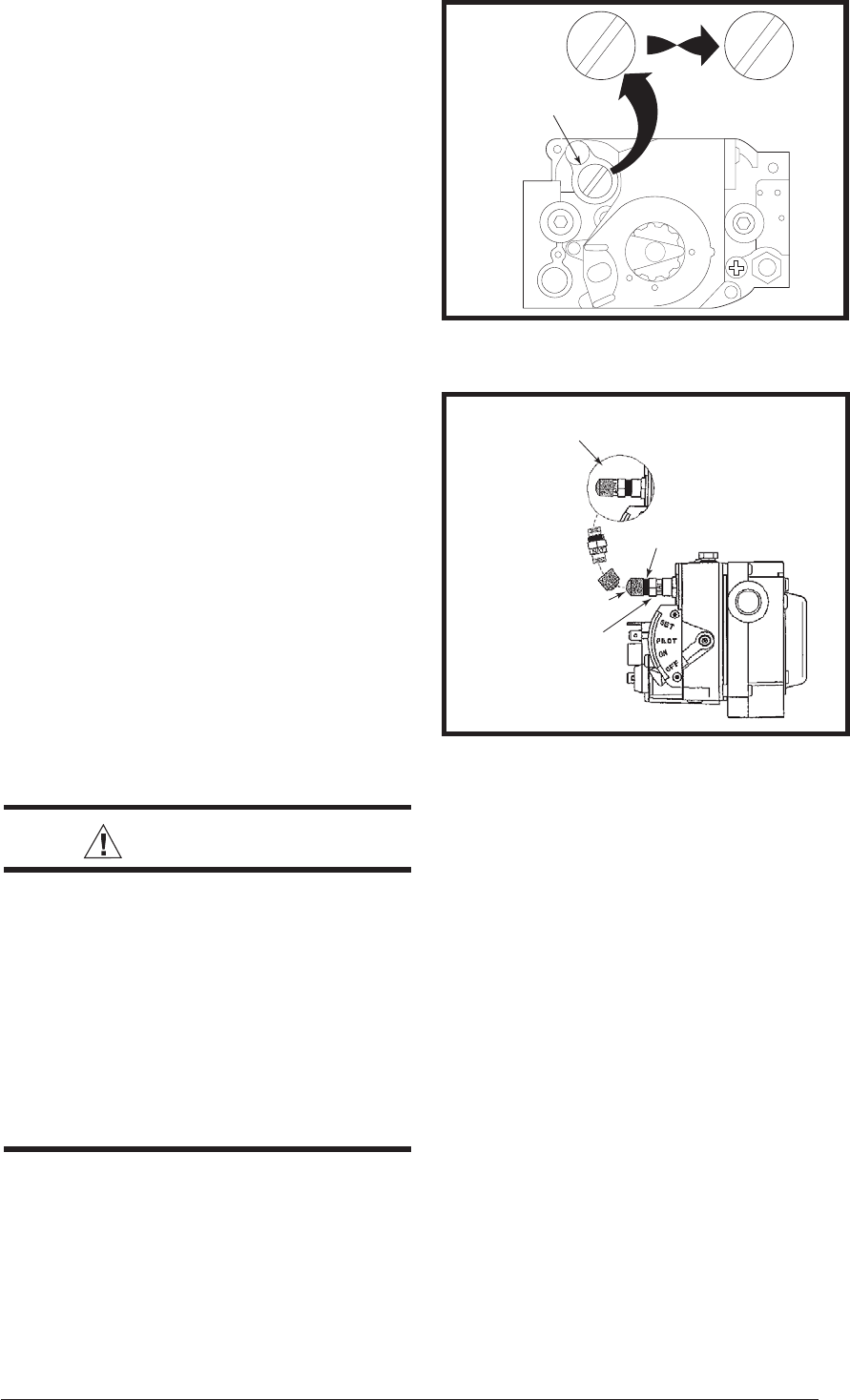

Figure 29. Robertshaw Gas Valve

High Altitude Conversion

High altitude conversion with this furnace

depends on the installation altitude and the

heating value of the gas. The installation of this

furnace at altitudes above 2,000 feet must meet

the requirements of the National Fuel Gas Code

or local jurisdiction. In Canada, the requirements

for high altitude are different and governed by

CGA B149.1. Please consult your local code

authority.

WARNING:

The reduction of input rating nec-

essary for high altitude installation

may only be accomplished with

factory supplied orifi ces. Do not

attempt to drill out orifi ces in the

fi eld. Improperly drilled orifi ces

may cause fi re, explosion, carbon

monoxide poisoning, personal

injury or death.

This furnace is shipped from the factory with

orifi ces and gas regulator settings for natural gas

operation at sea level altitudes. At 2000 feet, the

NFGC requires that this appliance be derated

4% for each 1000 feet of altitude. For example,

the input needs to be reduced 8% at 2,000 feet,

12% at 3,000 feet and etc. This deration is in

reference to the input rate and gas heating value

at sea level. See Table 12 (page 32).

6. For Honeywell gas valves with the regulator

converter (Figure 28, page 19):

a. Unscrew the pressure regulator cap and

check for the letters NAT or LP.

b. Invert the cap and tighten until snug.

7. For Robertshaw gas valves with the regulator

converter (Figure 29):

a. Remove the black cover and unscrew the

converter located on top of the gas valve.

b. Invert the converter: for LP the red ring will

be located at the bottom and the LP stamping

on the converter will appear right side up.

c. Screw converter back into the regulator,

hand tight plus 1/8 turn. Replace the black

cover on the converter top to protect the

threads.

8. Reassemble the burner assembly into the

furnace.

9. Reconnect the gas piping and electrical wires

to the gas valve.

10. Open the manual shut-off valve and follow

the Lighting and Operating instructions on

page 22.

Flue Gas Sampling

It may be necessary to take fl ue gas sampling

from oil and gas furnaces (M5S and M1B Series

Models) in order to check the performance after

furnace installation. A fl ue gas sample may

be taken from the heat exchanger, which is

located behind the hole of the top-front of blower

compartment.

1. Turn off all electric power to the appliance.

2. Remove the black plastic cap located above

the blower. Do not discard cap.

3. Drill a hole through the top of the blower

compartment. NOTE: Hole diameter should

be same size as sampling tube.

4. Insert sampling tube through the drilled hole

and into the heat exchanger.

5. After a complete check and adjustment

of furnace performance, seal the drilled

hole with a screw larger than the hole.

NOTE: Seal the screw threads with silicon

sealant - rated at least 500° F.

6. Plug the outside hole with the plastic cap

removed in step 3.