16

may require venting modifications (consult factory). The air inlet must be a minimum of 1'

vertically above the maximum snow level. It is very important that there are no other vents,

chimneys or air inlets in any direction for at least 4'.

All venting must be properly supported. The Munchkin is not intended to support any venting

whatsoever. All piping, glue, solvents, cleaners, fittings and components, must conform to ASTM

(American Society for Testing and Materials), and ANSI (American National Standards Institute). It is

recommended that you use one of the optional vent kits specifically designed for Munchkin installa-

tions, available from Heat Transfer Products, Inc. (KGAVT0601CVT [3 in.], KGAVT0501CVT [2 in.] or

V500 for the T50M/T80M or V1000 for the 80M/140M/199M). NOTE: When using the KGAVT601CVT

KIT, REMOVE THE 2 SCREENS FROM THE PROVIDED INLET TEE AND INSTALL THEM IN THE INLET

SOCKET AND OUTLET SOCKET (Y TEE CONNECTION) OF THE KIT PRIOR TO INSTALLING THE

SCHEDULE 40 PIPE AND GLUING.

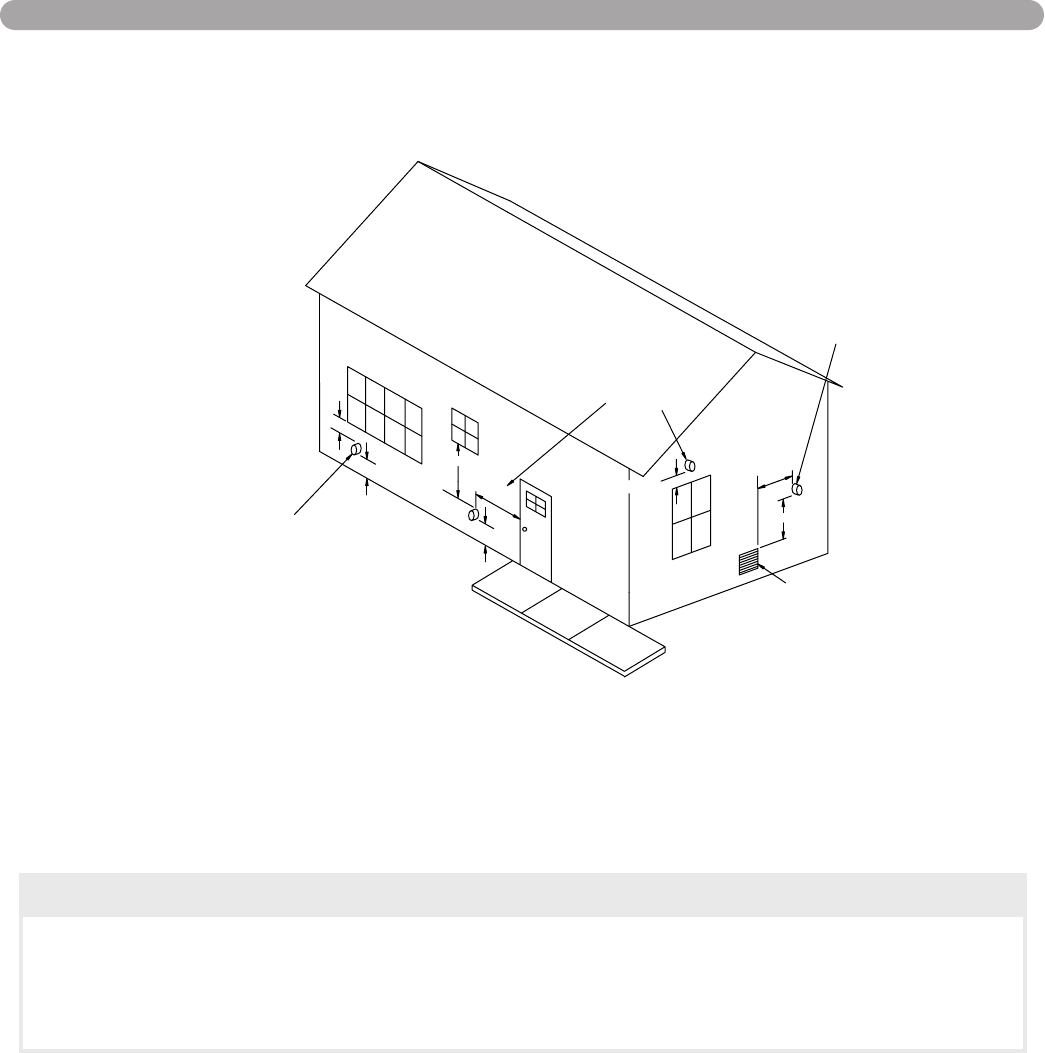

VENTING

12 in.minimum

Forced air

inlet

G

rade

3 ft.minimum

Less

than

10 ft.

term

inal

(see 10.8.1)*

d

raft v

ent

M

echan

ical

C

12 in.minimum

Direct vent terminal clearance

Minimum clearance, C

Input (Btu/hr)

4 ft.m

inim

um

12 in.minimum

minimum

ven

t term

inal

M

e

chanical draft

(see 10.8.2)*

4 ft.

Clearance (in.)

10,000 or less

10,001 to 50,000

Over 50,000

(see 10.8.3)*

6

9

12

For SI units: 1 ft = 0.305 m; 1 in. = 25.4 mm;

1 Btu/hr = 0.293 W

EXIT TERMINALS OF MECHANICAL DRAFT

AND DIRECT-VENT VENTING SYSTEM

* REFERENCE: THE NATIONAL FUEL GAS CODE

2002 EDITION

CAUTION

Flue Gas will condense as it exits the vent termination. This condensate can freeze on

exterior building surfaces which may cause discoloration of these surfaces.

Consideration should be given to the plume of condensation that exits the exhaust

which may affect the cosmetic appearance of the building.