OPERATION

Module

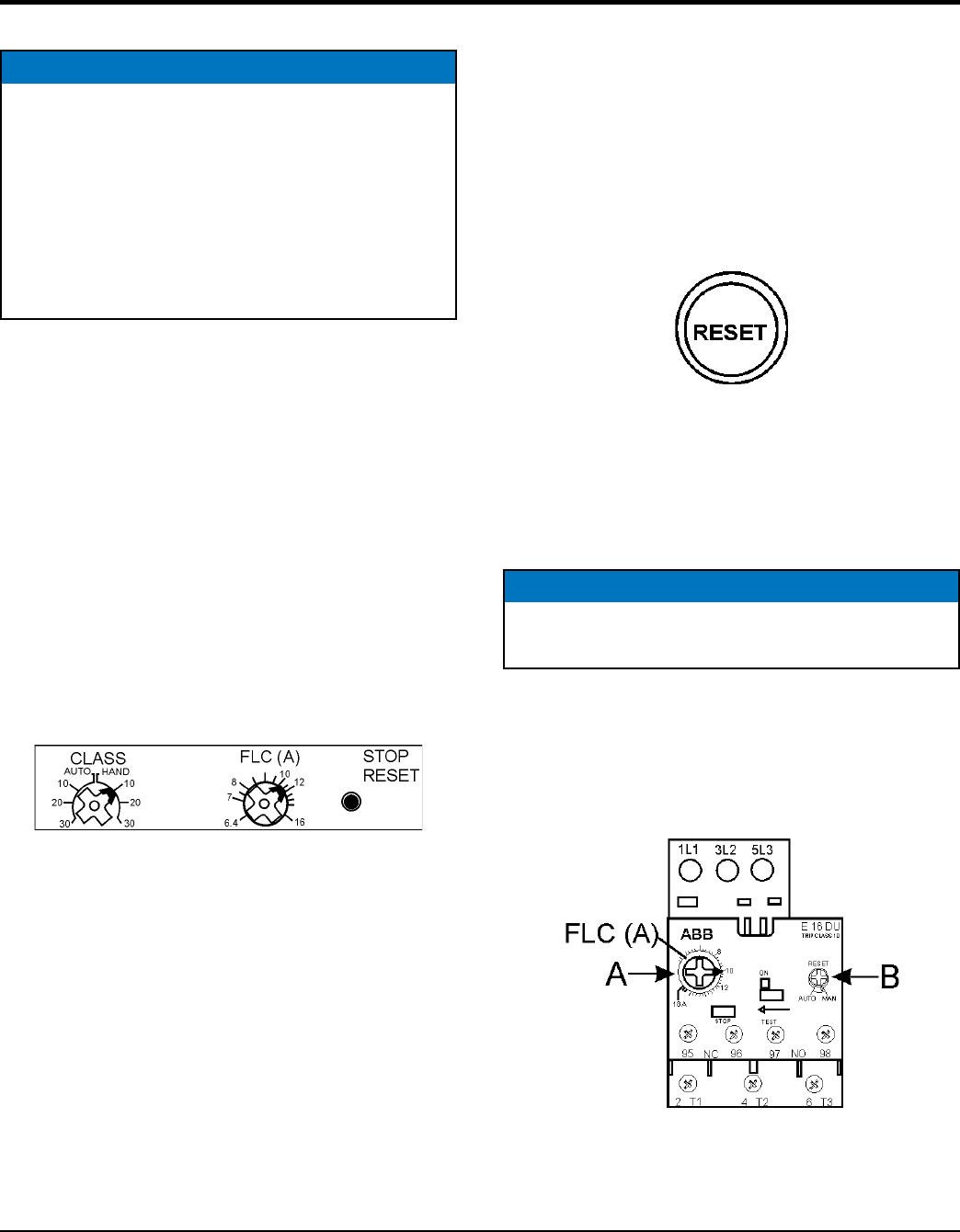

There are two dials on the Electronic Overload Module

(Figure 14) that require setting before the pump can be

used with the control box.

These dials are located on top of the overload module and

are labeled CLASS and FLC (A).

Use a phillips-head screw driver to adjust the dials to the

correct settings.

Full Load Current (FLC) Amps Dial Setting

1. Set the FLC (A) dial pointer (Figure 14) to 10.5. This

setting represents the running amps of the pump. This

information can be located on the pump's nameplate.

Figure 14. Electronic Overload

Module (Old Style)

Class Dial Setting

1. Depending on the application, Set the CLASS dial

pointer (Figure 14) to either (manual) or .

2. There are 3 groups of numbers on the CLASS dial that

range from 10 to 30. These numbers represent the trip

class of the thermal overload device.

3. Set the CLASS dial pointer to position 10. This setting

controls the reset function only. It does not affect the

ability of the pump to run with or without float switches.

NOTICE

make sure that the electronic overload

module supplied with the control box is set to the correct

amperage. This overload module must the

amperage requirements of the pump motor.

Using an electronic overload unit with incorrect settings

may result in serious damage to the pump.

check the nameplate on the pump to determine the

required amperage settings for the overload module.

This electronic control unit has two modes of reset. The

modes are defined as follows:

MODE 1

When the CLASS dial on the electronic overload module

is in the position (manual) the reset button (Figure 15)

on the front of the control box must be pushed to reset the

unit (restore power) in the event of an overload.

Figure 15. Control Box Reset Button

MODE 2

When the CLASS dial on the electronic overload module

is in the position (automatic mode) the unit will

automatically be reset in the event of an overload

Module

There are two dials (A and B) on the Electronic Overload

Module (Figure 16) that require setting before the pump

can be used with the control box.

Figure 16. Electronic Overload

Module (New Style)

NOTICE

The CB200 Control Box (old style) is shipped from the

factory with the CLASS dial set to the position.