ST2010 SERIES SUBMERSIBLE PUMP • OPERATION AND PARTS MANUAL — REV. #3 (12/07/12) — PAGE 17

CONTROL BOX INSTALLATION

CONTROL BOX MOUNTING

Mount the control box in an upright vertical position. Make

sure the control box is securely fastened to a flat surface,

that is free of dust, dirt, moisture or any elements that

may contaminate or erode the electronic components of

the control box.

SINGLE-PHASE POWER INSTALLATION (INPUT)

The ST2010, ST2010A, ST2010CUL, and ST2010TCUL

submersible pumps require 115 V, 60 Hz, single-phase

power for normal operation. The ST2010B requires 230 V,

60 Hz, single-phase power.

If you cannot determine what your pump's power

requirements are, look at the vendor supplied identification

name tag attached to the pump or contact Multiquip's

Service/Technical Assistance department.

DANGER

The ST2010 Series submersible

pumps are designed to work with a

control box. The control box contains

the necessary electronics (float

switch connections) to operate

the pump. Remember the control

box contains hazardous voltages.

Disconnect all sources of power

before installing or servicing. There exists the possibility

of electrocution, electric shock or burn, which can cause

severe bodily harm or even death!

CAUTION

This control box should only be installed or serviced by

a licensed electrician or qualified personnel.

CAUTION

Applying incorrect power (voltage phasing) to the

submersible pump can cause severe damage to the

pump. Please make sure that the correct voltage and

phase are transferred to the pump at all times.

POWER CORD REQUIREMENTS

When routing the 115 VAC/230V, 60 Hz, single-phase power

via a power cord to the control box, always use the correct

wire size. Please refer to Table 4 below (Cord Length/Wire

Size) to determine the correct wire size. Incorrect wire size

can adversely affect the performance of the pump.

CONNECTING DUAL FLOAT SWITCH (SW-1WOP)

TO CONTROL BOX

1. Remove the float switch input connector housing, then

route the float switch wires through the cable gland on

the control box. Attach the wires of the float switch to

the terminal block as indicated by Table 5, Figure 7

and Figure 8.

2. Tighten the connector housing to ensure a tight fit

between the cord and the connector body. This will

prevent the cable from pulling out of the terminal block

and also prevent moisture from entering the control box.

3. Determine the length of the float switch wires, then

secure float switch wires to pump discharge hose. See

Figure 3 and Table 3 to determine the pumping range.

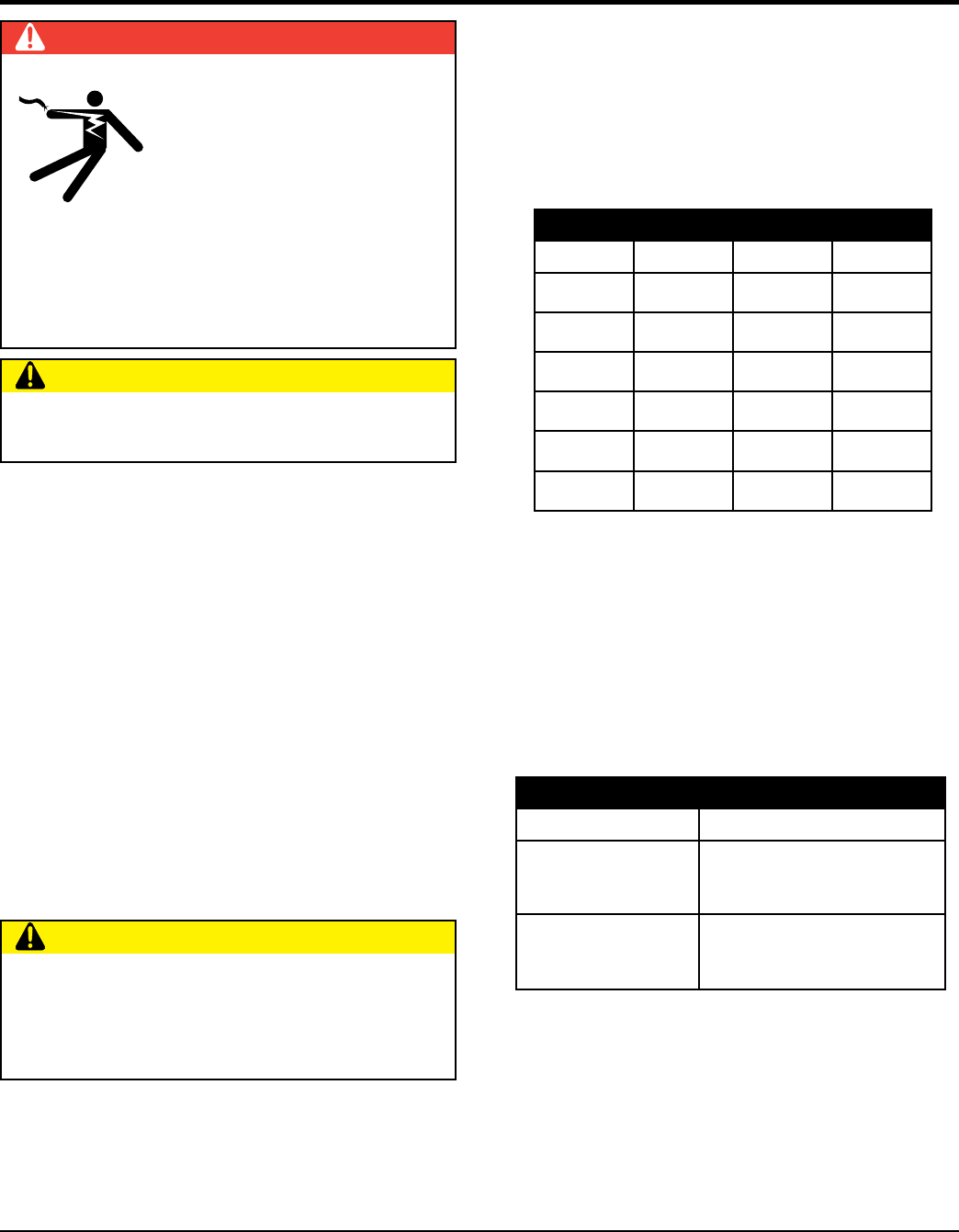

Table 4. Cord Length and Wire Size

AMPS 50 FT. 100 FT. 150 FT.

6 16 AWG 16 AWG 14 AWG

8 16 AWG 14 AWG 12 AWG

10 16 AWG 14 AWG 12 AWG

12 14 AWG 14 AWG 12 AWG

14 14 AWG 12 AWG 10 AWG

16 12 AWG 12 AWG 10 AWG

Table 5. Float Switch Connections

Float Switch Terminal Block Number

START

TERMINAL 1 (BLACK)

TERMINAL 2 (WHITE)

STOP

TERMINAL 7 WHITE)

TERMINAL 8 (BLACK))