PAGE 32 — HTN 31V

HTN-SERIES • RIDE-ON POWER TROWEL — OPERATION MANUAL — REV. #0 (06/06/07) — PAGE 32

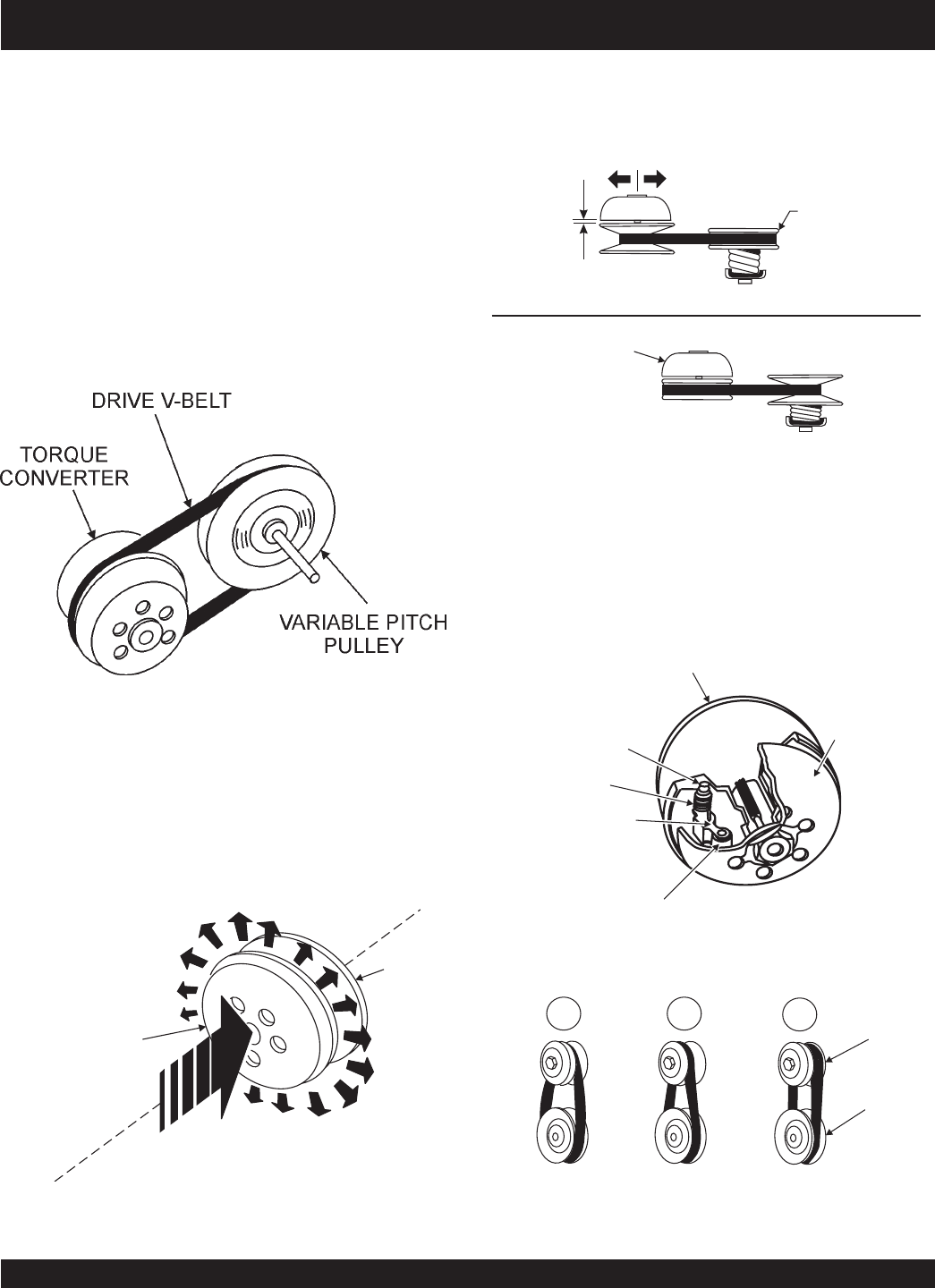

NEUTRAL LOW SPEED HIGH SPEED

DRIVE

PULLEY

DRIVEN

PULLEY

A

B

C

Figure 26. Pulley Conditions

HTN-SERIES— MAINTENANCE

The "Variable Pitch Pulleys" have one

fixed face

, and one

moveable

face

. The

drive

pulley ( torque converter, Figure 25) moveable face

is controlled by roller weight arms and springs, which change

position according to engine speed. The

driven

pulley

moveable

face

is controlled by a spring and belt tension.

Fig. 25. Variable Pitch Pulley

DRIVE

PULLEY

DRIVE

PULLEY

LOW OUTPUT

SPEED

DRIVEN PULLEY

LOW ENGINE RPM

HIGH ENGINE RPM

DRIVEN PULLEY

HIGH OUTPUT

SPEED

CENTRIFUGAL FORCE

DISTANCE

MOVEABLE

FACE

TRAVELS

MOVEABLE FACE

IS CONTROLLED

BYA SPRING

AND BELT TENSION

MOVABLE FACE IS

CONTROLLED BY

ROLLER WEIGHTARMS

AND SPRINGS

Fig. 24. Pulley Interaction

Centrifugal force pushes the roller arms against the ramp plate,

forcing the moveable face toward fixed face squeezing the belt. (see

Figure 24 below)

WEIGHT

RAMP

PLATE

BUSHING

ROLLER ARM

SPRING

DRIVE PULLEY

Drive Pulley

The "Drive Pulley" uses centrifugal force (Figures 23 and 24)

to create a belt squeeze force transmitted at the pulley faces.

This condition functions as an automatic clutch and transmission.

C

E

N

T

R

I

F

U

G

A

L

F

O

R

C

E

BELT SQUEEZE

FORCE

FIXED

FACE

VARIABLE

FACE

DRIVE PULLEY

(

TORQUE CONVERTER

)

Figure 23. Torque Converter (Centrifugal Force)

Fig. 22 Torque Converter/Variable Pitch Pulley

The HTN-SERIES Ride-On Power Trowel is equipped with a

"Torque Converter" which supplies torque to both the left and right

gearboxes.

The function of the torque converter is to automatically deliver the

correct amount of torque required by the trowel under all load

conditions. This enables the trowel to deliver the necessary torque

for float pan applications and the high rotor speeds required for

burnishing concrete.

The torque converter used in the HTN SERIES Ride-On Power

Trowel is a variable pitch pulley type (Figure 22) connected by a

drive belt.

Drive System Theory of Operation