11

7.2. Test run

7.2.1. Using remote controller

Refer to the indoor unit installation manual.

• Be sure to perform the test run for each indoor unit. Make sure each indoor

unit operates properly following the installation manual attached to the unit.

• If you perform the test run for all indoor units at once, you cannot detect any

erroneous connection, if any, of the refrigerant pipes and the connecting wires.

* The compressor operation is not available for 3 minutes at least after the

power is supplied.

• The compressor can emit noise just after turn on the power supply or in case

of low outside air temperature.

About the restart protective mechanism

Once the compressor stops, the restart preventive device operates so the compres-

sor will not operate for 3 minutes to protect the air conditioner.

7.2.2. Using SW3 in outdoor unit

Note:

In case of the test run from outdoor unit, all indoor units operate. Therefore,

you can not detect any erroneous connection of refrigerant pipes and the con-

necting wires. If it aims at detection of any erroneous connection, be sure to

carry out the test run from remote controller with reference to “7.2.1 Using

remote controller”.

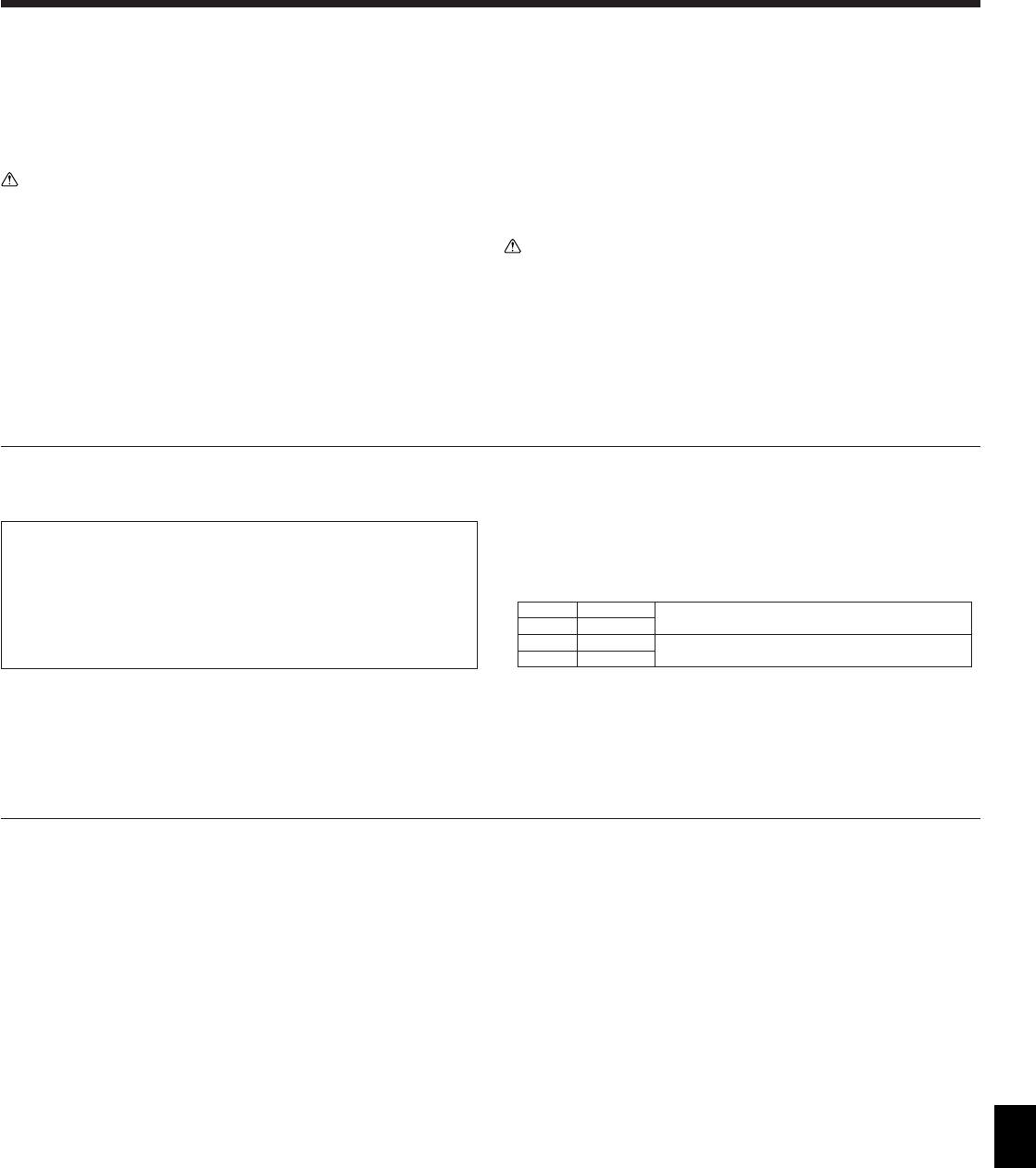

SW3-1 ON

Cooling operation

SW3-2 OFF

SW3-1 ON

Heating operation

SW3-2 ON

* After performing the test run, set SW3-1 to OFF.

• A few seconds after the compressor starts, a clanging noise may be heard from the

inside of the outdoor unit. The noise is coming from the check valve due to the small

difference in pressure in the pipes. The unit is not faulty.

The test run operation mode cannot be changed by DIP switch SW3-2 during

the test run. (To change the test run operation mode during the test run, stop

the test run by DIP switch SW3-1. After changing the test run operation mode,

resume the test run by switch SW3-1.)

7. Test run

7.3. Refrigerant collecting (Pump down)

Before removing air conditioners for transfer to another location, always close the

stop valve (for both liquid and gas pipes) located at the outdoor unit, then remove the

indoor and outdoor units. At this time, the refrigerant in the indoor unit will be dis-

charged. To minimize the refrigerant discharged, a pump down operation is required.

This operation collects the refrigerant present inside the air conditioner and sends it

into the heat exchanger located in the outdoor unit.

Pump down procedure

1 Operate all indoor units in cooling mode and check that the operation mode has

changed to “COOL”. (Set the units so that cooling operation mode is activated

during the pump down operation (when the TEST RUN button is pressed).)

2 Connect a gauge manifold valve (with pressure gauge) to the stop valve of the

gas pipe, to enable measurement of refrigerant pressure.

3 After setting the outdoor service switch SW3-2 to OFF, set the switch SW3-1 to

ON. (The unit will start in cooling mode.)

4 After the cooling operation has been carried out for approximately five minutes,

set the outdoor service switch SW2-4 (pump down switch) from OFF to ON.

5 Close the stop valve on the liquid pipe, with the cooling operation still ON. (Pump

down operation will start.)

6 When the reading of the pressure gauge reaches 0 to 0.1 MPa [14.5 PSIG] or

when approximately 5 minutes have elapsed following the start of the pump down

operation, fully close the stop valve on the gas pipe and stop the air conditioner

by setting the switch SW3-1 to OFF immediately.

7 Set the outdoor service switch SW2-4 from ON to OFF.

8 Remove the gauge manifold valve and put the cap back onto each stop valve.

Note:

1 Never carry out pump down operation if the amount of refrigerant inside

the indoor unit is larger than the amount of charge-less refrigerant.

Carrying out a pump down operation when the amount of refrigerant ex-

ceeds the amount of charge-less refrigerant will cause an extreme pres-

sure rise and may result in an accident.

2 Do not continue to operate for a long time with the switch SW2-4 set to ON.

Make sure to switch it to OFF after pump down is completed.

3 Test run can be carried out when the test run switch SW3-1 is ON. Switch

SW3-2 is used to operating mode selection. (On: Heating, OFF: Cooling)

4 Time required for a pump down operation is three to five minutes after the

stop valve on the liquid pipe has been closed. (It depends on the ambient

temperature and amount of refrigerant inside the indoor unit.)

5 Ensure that the reading of the pressure gauge does not drop below 0 MPa

(0 PSIG). If it drops 0 MPa [0 PSIG] (i.e. vacuum is created), air will be drawn

into the unit if there are any loose connections.

6 Even if the reading of the pressure gauge does not drop below 0 MPa [0

PSIG], always stop the pump down operation within approximately five min-

utes after the stop valve on the liquid pipe has been fully closed.

7.1. Before test run

s After completing installation and the wiring and piping of the indoor and

outdoor units, check for refrigerant leakage, looseness in the power supply

or control wiring, wrong polarity, and no disconnection of one phase in the

supply.

s Use a 500-volt M-ohm tester to check that the resistance between the power

supply terminals and ground is at least 1 MΩ.

s Do not carry out this test on the control wiring (low voltage circuit) termi-

nals.

Warning:

Do not use the air conditioner if the insulation resistance is less than 1 MΩ.

Insulation resistance

After installation or after the power source to the unit has been cut for an extended

period, the insulation resistance will drop below 1 MΩ due to refrigerant accumulat-

ing in the compressor. This is not a malfunction. Perform the following procedures.

1. Remove the wires from the compressor and measure the insulation resistance of

the compressor.

2. If the insulation resistance is below 1 MΩ, the compressor is faulty or the resist-

ance dropped due the accumulation of refrigerant in the compressor.

3. After connecting the wires to the compressor, the compressor will start to warm

up after power is supplied. After supplying power for the times indicated below,

measure the insulation resistance again.

• The insulation resistance drops due to accumulation of refrigerant in the com-

pressor. The resistance will rise above 1 MΩ after the compressor is warmed

up for four hours.

(The time necessary to warm up the compressor varies according to atmos-

pheric conditions and refrigerant accumulation.)

• To operate the compressor with refrigerant accumulated in the compressor,

the compressor must be warmed up at least 12 hours to prevent breakdown.

4. If the insulation resistance rises above 1 MΩ, the compressor is not faulty.

Caution:

• The compressor will not operate unless the power supply phase connection

is correct.

• Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch can result in

severe damage to internal parts. Keep the power switch turned on during the op-

erational season.

s The followings must be checked as well.

• The outdoor unit is not faulty. LED on the control board of the outdoor unit flash

when the outdoor unit is faulty.

• Both the gas and liquid stop valves are completely open.