28

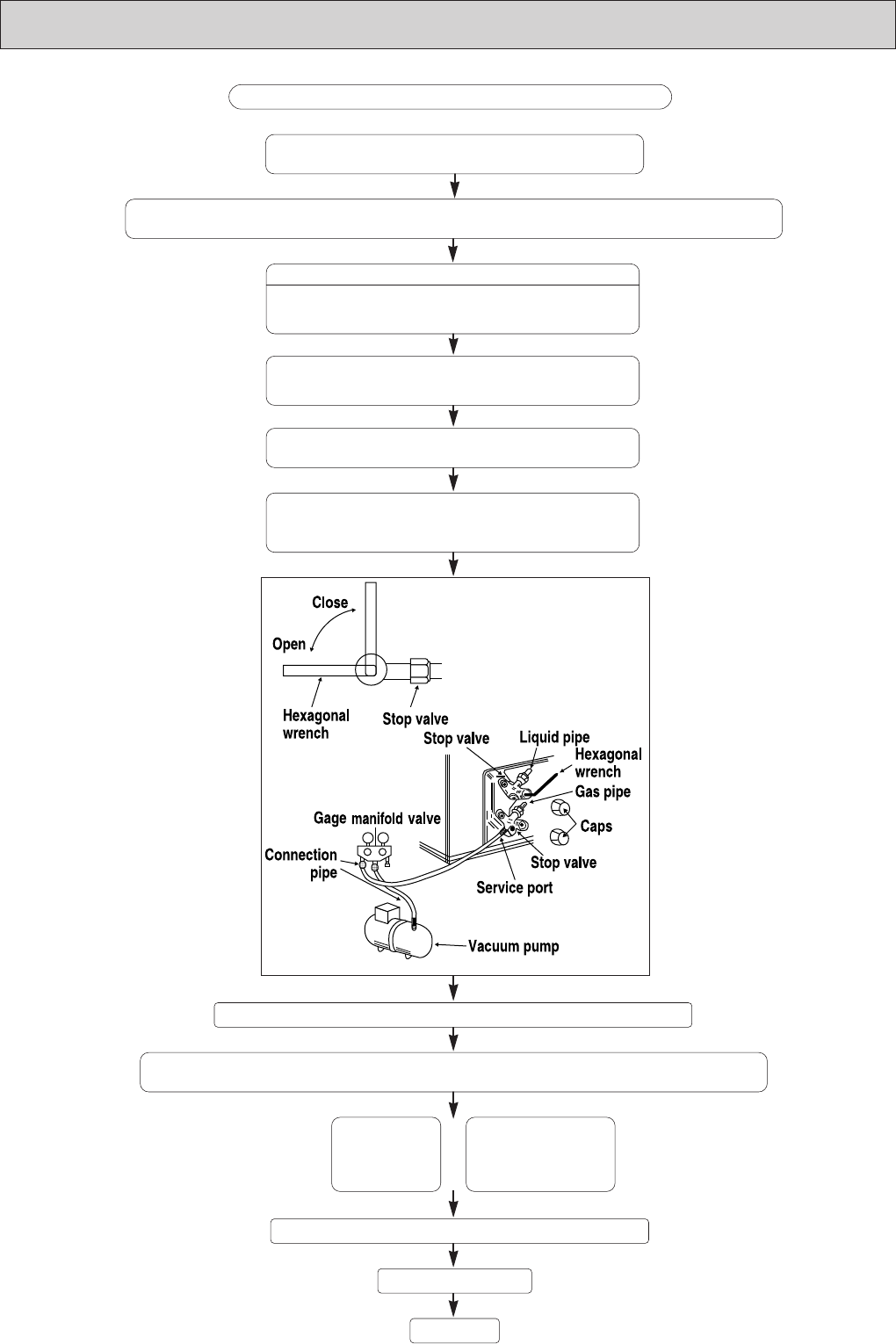

EVACUATION PROCEDURES(AIR PURGE)

Pipe length :

7m maximum

No gas charge

is needed

Pipe length

exceeding 7m

Charge the prescribed

amount of gas

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

After refrigerant pipes are connected and evacuated, fully open all stop valves on gas and liquid pipe sides.

Operating without fully opening lowers the performance and causes trouble.

Remove the gage manifold valve quickly from the service port of the stop valve.

Leave it as it is for one or two minutes. Make sure the pointer

of the gage manifold valve remains in the same position.

Check the vacuum with the gage manifold valve, then close

the gage manifold valve, and stop the vacuum pump.

Run the vacuum pump for more than 15 minutes and at this

time confirm that the pressure gage indicates –0.1 Mpa.

When vacuuming

Connect the gage manifold valve and the vacuum pump to

the service port of the stop valve on the liquid pipe side of the

outdoor unit.

Connect the refrigerant pipes (both the liquid and gas pipes)

between the indoor and the outdoor units.

Remove the service port cap of the stop valve on the side of the outdoor unit gas pipe.(The stop valve will not

work in its initial state fresh out of the factory (totally closed with cap on))

OB207t-1qxp 25/9/97 8:53 PM Page 28