2

3

IMPORTANT SAFETY INSTRUCTIONS

WARNING READ ALL SAFETY WARNINGS AND ALL INSTRUCTIONS.

Failure to follow the warnings and instructions may result in electric shock, fi re and/or serious

injury, as well as instrument damage and/or damage to the equipment being tested.

Save these instructions - This operator’s manual contains important safety and operating

instructions for the MILWAUKEE 400 Amp Clamp Meter. Before using, read this operator’s

manual and all labels on the Clamp Meter.

DANGER

Never make measurement on a circuit in which voltage over 600 volts AC exists. Use only

leads rated 600V or better.

Do not attempt to make measurement in the presence of fl ammable gasses. Otherwise, the

use of the instrument may cause sparking, which can lead to an explosion.

Transformer jaw tips are designed not to short the circuit under test. If equipment under test

has exposed conductive parts, however, extra precaution should be taken to minimize the

possibility of shorting.

Do not hold the meter above hand-stop.

Never attempt to use the instrument if its surface or your hand is wet.

Do not exceed the maximum allowable input of any measuring range.

Only use test leads on unenergized circuits unless absolutely necessary.

Check tool functionality on a known circuit fi rst. Never assume tool is working. Assume circuits

are live until they can be proven de-energized.

Do not ground yourself while measuring. Avoid body contact with earthed or grounded sur-

faces such as pipes, radiators, ranges and refrigerators.

Never open the battery cover during a measurement.

The instrument is to be used only in its intended applications or conditions. Otherwise, safety

functions equipped with the instrument doesn’t work, and instrument damage or serious

personal injury may be caused.

To reduce the risk of injury from shock and arc blasts, always wear personal protective

equipment where live conductors are exposed.

WARNING

Never attempt to make measurement if any abnormal conditions, such as broken case and

exposed metal parts are found on the instrument.

Do not rotate the rotary dial while the test leads are being connected.

Verify proper operation on a known source before use or taking action as a result of the in-

dication of the instrument.

Do not install substitute parts or make any modifi cation to the instrument. For repair or re-

calibration, return the tool to a factory Service/Sales Support Branch or authorized service

station.

Do not try to replace the batteries if the surface of the instrument is wet.

Disconnect all the cords and cables from the object under test and power off the instrument

before opening the battery cover for battery replacement.

This tool is designed to be powered by 2-AAA batteries properly inserted into the MILWAUKEE

Clamp Meter. Do not attempt to use with any other voltage or power supply.

Install battery according to polarity (+ and –) diagrams.

Do not leave batteries within the reach of children.

Do not mix new and used batteries. Do not mix brands (or types within brands) of batteries.

Properly dispose of used batteries.

Do not incinerate or dismantle batteries.

Under abusive conditions, liquid may be ejected from the battery, avoid contact. If contact

accidentally occurs, fl ush with water. If liquid contacts eyes, additionally seek medical help.

Liquid ejected from the battery may cause irritation or burns.

CAUTION

Set the rotary dial to an appropriate position before starting measurement.

Firmly insert the test leads.

Disconnect the test leads from the instrument for current measurement.

Do not expose the instrument to the direct sun, high temperature and humidity or dew fall.

Altitude 2000m or less. Appropriate operating temperature is within 14°F and 122°F (-10°C

and 50°C).

This instrument isn’t dust & water proofed. Keep away from dust and water.

Be sure to power off the instrument after use. When the instrument will not be in use for a long

period, place it in storage after removing the batteries.

Use a cloth dipped in water or neutral detergent for cleaning the instrument. Do not use

abrasives or solvents.

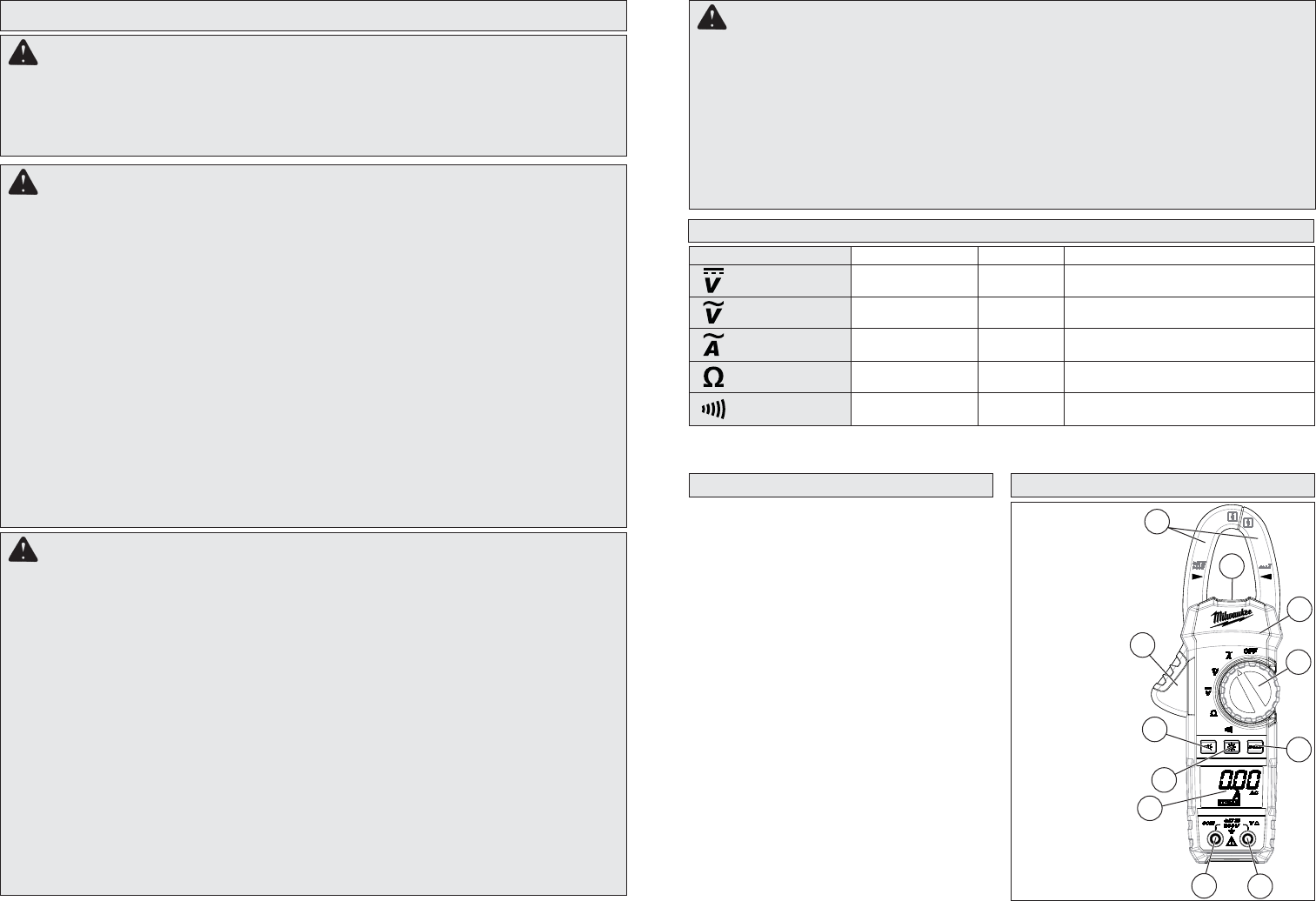

Functions

Dial Position Range Resolution Accuracy

Voltage DC 400.0/600V 0.1V/1V ± 1.0%rdg ± 5dgt

Voltage AC 400.0V/600V 0.1V/1V ± 1.2% ± 5dgt (50 to 400Hz)

Current AC 40.00/400.0A 0.01A/0.1A

± 1.8%rdg ± 5dgt(50/60Hz)

± 3.0%rdg ± 5dgt(60 to 400Hz)

Resistance 4000 1 ± 1.0%rdg ± 3dgt

Continuity

Cont Buzzer

0-400.0

0.1

± 1% ± 5dgt

Beeper sounds at 30 ohms and below.

* These instruments are True-RMS sensing. All voltage and current readings are True-RMS values.

* All AC ranges are specifi ed from 0.25% to 100% of range.

General Specifi cations FUNCTIONAL DESCRIPTION

1. Current sensing jaws

2. Jaw opening trigger

3. Worklight on/off

4. Backlight button

5. Display

6. COM Terminal input

7. V Terminal input

8. Hold button

9. Rotary dial

10. Hand-stop

11. Worklight LED

Accuracy is specifi ed for 1 year after calibration, at

operating temperatures of 64°F to 82°F (18°C to

28°C), with relative humidity at 0 % to 85 %.

Maximum voltage between any terminal and

earth ground .... 600 V

Jaw Opening (maximum conductor size) ....

1.0” (25.4 mm)

Temperature ....

Operating: 14°F to 122°F (-10°C to 50°C)

Storage: -40°F to 140°F (-40°C to 60°C)

Temperature Coefficient .... 0.1 x (specified

accuracy)/°C (<18°C or >28°C)

Operating Altitude.... 2,000 meters

Drop Test .... 1 Meter

Battery .... 2 AAA, NEDA 24 A, IEC LR03

Battery Life .... Approx. 20 hours with all lights on,

100 hours without backlight.

Safety Compliances .... EN61010-1,

UL 61010-1, EN61010-031 (Probes),

IEC 61010-2-32 (Clamp Assemblies),

IEC/EN 61010-1 2nd Edition for measurement

Category III, 600 V,

Pollution Degree 2, EMC EN61326-1

Certifi cations .... cULus, CE

1

3

5

6

4

2

8

11

9

7

10