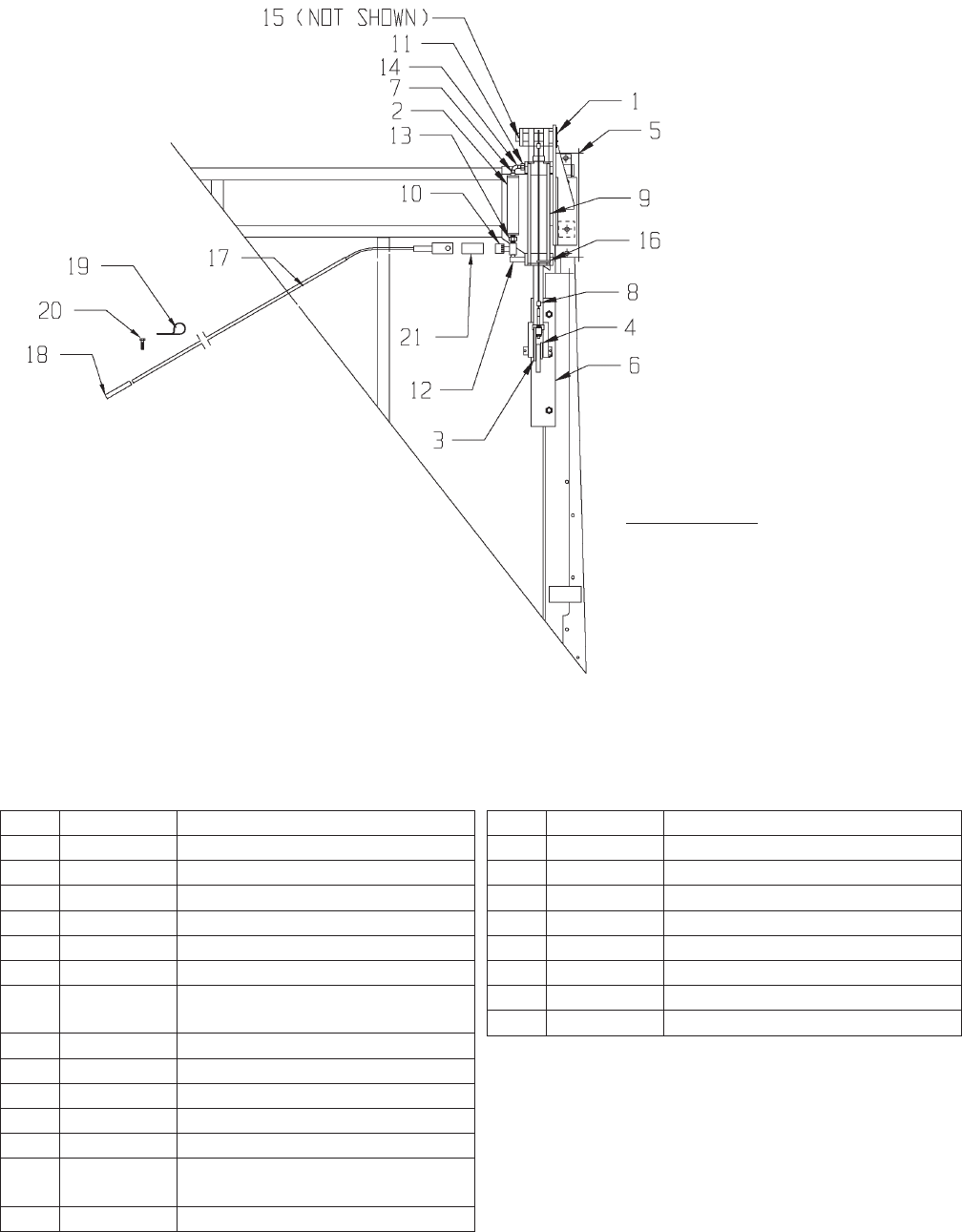

3200 & 4200 Series -- 60 --

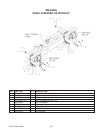

GATE

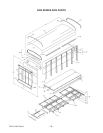

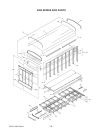

3100/3200/4100/4200 BOX

KEY PART NO. DESCRIPTION

4200-GATE Gate Delay Closing Option

1 25-8092-1 Gate Regulator Top Shaft

2 25-8095 Oil Reservoir Assembly

3 25-8096 Gate Release Trip Arm Assembly

4 25-8097-1 Lower Sleeve Spacer

5 25-8099 Top Cylinder Bracket

6 25-8100 Lower Mount Plate Welded As

-

sembly

7 30-0015 1/4” Fitting x 90 Degree Elbow

8 25-8098 Cable Eyebolt Assembly

9 55-0093 Hydraulic Cylinder

10 55-0094 Flow Control

11 55-0095 1/8” to 3/8” NPT Reducer

12 55-0096 3/8” NPTF x 90 Degree Male Pipe

Elbow

13 55-0097 3/8” to 3/8” Nipple

KEY PART NO. DESCRIPTION

14 735-.25CT 1/4” Copper Tubing (.25 Ft. Req)

15 823-19-2 3/16 x 2” Cotter Pin

16 952-0001-7 Nylon Tie Strap

17 25-8101 Ground Control Rod Assy. W/Grip

18 51-0007 Handle Grip

19 933-3804 5/16 x 4” Eyebolt

20 825-25-1Z 1/4x1" Self Tapping Screw

21 25-8102-2 Drag Sleeve (Hose)

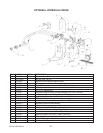

GATE DELAY ADJUSTMENTS

When the gate is completely closed (Tight to rear upright) cable and eyebolt assembly should be adjusted so cable

has no slack. Cable should be tight but not overtightened. If cable and eyebolt is overtightened lower cylinder will trip

out of the L-shaped slot on the lower bracket too soon and the gate will try toclose before the cylinder is stroked out. If

the cable and eyebolt is too loose the lower cylinder will not trip out of the L-shaped slot and the cylinder will reach its

maximum stroke and the gate will still not be in the closed position. The gate will be held open by the top cylinder

bracket and the bracket may become damaged over time. Eyebolt and cable will need to be adjusted periodically to

maintain proper operation.

OIL CAPACITY

WITH 6” OF RAM ROD SHOWING

FILL TANK TO TOP WITH LITE

HYDRAULIC OIL.