UNLOADING THE FORAGE BOX

Pull the forage box into position and park so that the

cross conveyor discharge opening is in alignment with

the silo filling blower hopper. If the forage box is

equipped with a fold down cross conveyor extension, it

can be lowered before pullingin front ofthe blower. After

a couple of parking trails, you may become familiar with

the correct parking place and be able to lower the cross

conveyor extension after parking. Always park the for

-

age box and unloading tractor in a straight line. Minimize

the unloading angle on the PTO drive shaft to prevent

wearing of universal joints when connected to the un

-

loading tractor PTO. Shift the unloading tractor to “Neu

-

tral” or “Park” and set the brakes.

NOTE: Normal operation is using a farm tractor. If using

some other vehicle, exercise equivalent caution when

parking and exiting this vehicle.

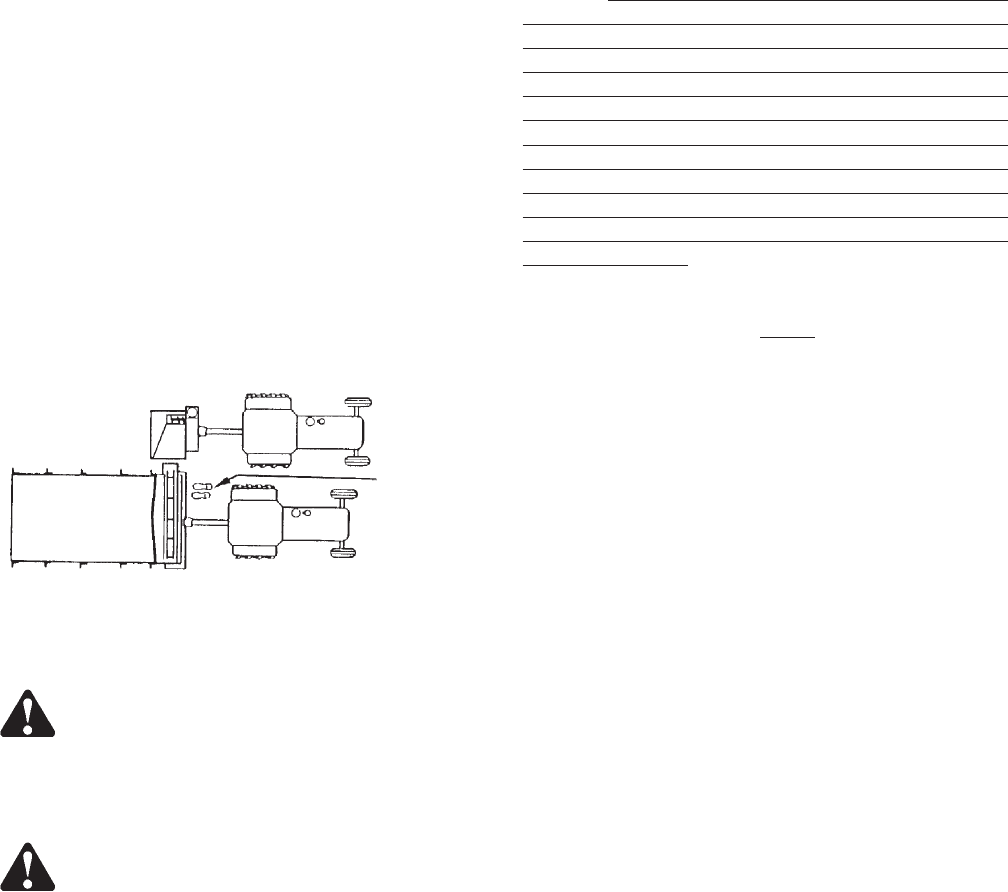

Properly dismount from the tractor and approach the for

-

age box by walking along the left side of the tractor as

shown in the following diagram. Do not approach the for

-

age box from the right side of the machine (left hand un-

load). Approach the left front area of the forage box, as

this is where the control levers are located. Standing in

the operator position will not require crossing the PTO

drive shaft at any time during the unloading operation.

WARNING: DO NOT STEP OVER THE PTO

DRIVE SHAFT. STAY WELL CLEAR OF THE PTO AT

ALL TIMES. FAILURE TO HEED MAY RESULT IN SE

-

RIOUS PERSONAL INJURY OR DEATH.

WARNING: DO NOT STEP UP ON ANY PART

OF THE FORAGE BOX AT ANY TIME. FAILURE TO

HEED MAY RESULT IN SERIOUS PERSONAL IN

-

JURY OR DEATH.

START UP PROCEDURES

Remove PTO drive shaft from the forage box PTO stor

-

age bracket and connect to the tractor PTO. Be sure the

PTO yoke is securely locked to the tractor PTO. If using

an optional hydraulic drive,couple the hydraulic hoses to

the power supply.

Check that the INDEPENDENT OUTFEED CLUTCH

control lever is in the “Stop” position and the VARIABLE

SPEED & HI-LO RANGE control levers are in the “Neu

-

tral” positions.

NOTE: The INDEPENDENT OUTFEED CLUTCH,

VARIABLE SPEED, and HI-LO RANGE control levers

must be in their “Stop” or “Neutral” positions when en

-

gaging and disengaging the PTO drive shaft (or optional

hydraulic drive). All forage box control lever selections

are to be made while the PTO (or hydraulic) power is in

operation. If the control levers are engaged before

power is applied, damage may occur to the Variable

Speed drive or Independent Outfeed Clutch drive or

both. Failure to follow correct operating procedures

may cause equipment damage and may void the manu-

facturers warranty.

At this time, start the silo filling blower. Return to the for-

age box unloading tractor, slowly

engage the PTO, and

set the engine speed from 1300-1500 rpm.to give a PTO

speed of 300-375 rpm.

Return to the operator’s position adjacent to the forage

box controls. Intermittently engage the INDEPENDENT

OUTFEED CLUTCH control lever to the “Run” position

and allow the cross conveyor to empty out any accumula

-

tion of forage in the front unloading unit. After the forage

has emptied, fully engage the INDEPENDENT

OUTFEED CLUTCH controllever into the “Run”position.

Next, engage the VARIABLE SPEED control lever to

clear forage from the three unloading augers. Intermit

-

tently move the lever between “Neutral” and the 1

st

and/or 2

nd

notch settings on the control quadrant. This

will engage and disengage theaugers at aslow speedto

clear them without the main apron moving forward; be

-

cause the HI-LORANGE control lever isstill in “Neutral.”

With the augers cleared and running and the VARIABLE

SPEED control lever in a slow speed setting, move the

RANGE control lever to “LO” and the main apron chain

will begin to move forward. Moving the VARIABLE

SPEED control lever down on the control quadrant will

increase speed of both auger rotation and main apron

forward travel. Keep increasing speedof the VARIABLE

SPEED control to regulate rate of forage box unloading

speed to match the capacity of the silo filling blower.

3200 & 4200 Series -- 16 –

OPERATOR TRAFFIC PATTERN

LH Side

OPERATOR

POSITION

RH Side