TWO SPEED LUBRICATION AND MAINTENANCE

WARNING: DISCONNECT PTO DRIVE SHAFT (OR OPTIONAL HYDRAULIC POWER SOURCE) BE

-

FORE CLEANING, ADJUSTING, LUBRICATING OR SERVICING THIS MACHINE. FAILURE TO HEED MAY RE

-

SULT IN SERIOUS PERSONAL INJURY OR DEATH.

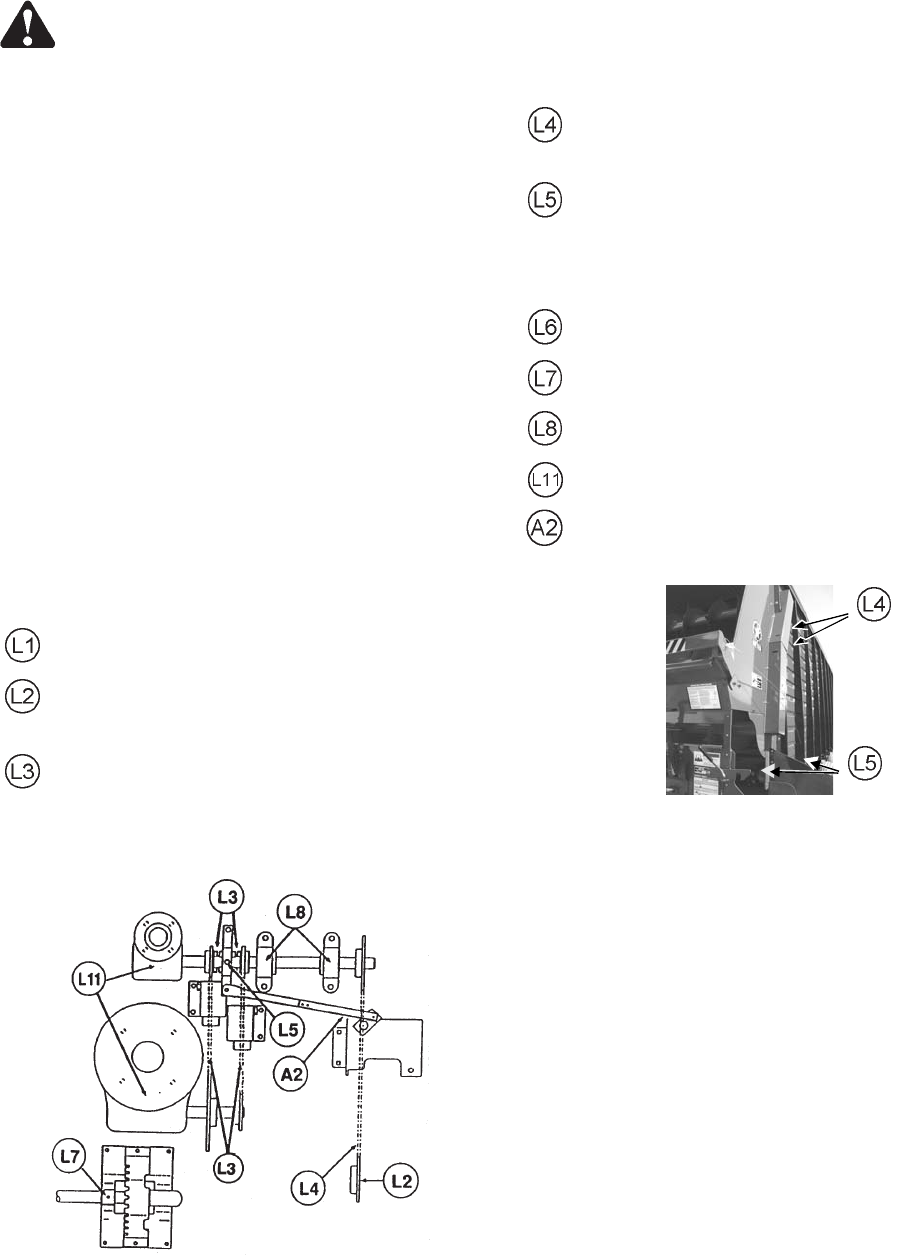

ROLLER CHAIN DRIVES

The roller chain drives are tensioned by automatic spring

loaded tension blocks.

RANGE CONTROL CLUTCH ENGAGE

-

MENT

With the range control lever set to neutral, the engaging

jaw clutch should be about midway between the “LO and

“HI” sprocket clutch jaws on the splined shaft. Neither

should be engaged. When the lever is moved to “LO” the

engaging jaw clutch should mate with “LO” speed

sprocket clutch and have about 1/16” of clearance. Like

-

wise for the “HI” speed when the lever is moved to “HI”.

This engagement is adjusted by changing the length of

over-lap on the two, slotted hole linkage bars.

DAILY LUBRICATION MAINTENANCE

(every 8-10 loads)

Grease PTO drive shaft joints (not illustrated).

Grease front idler sprocket - wipe off excess grease

from exterior.

Oil roller chains and HI-LO range jaw clutch.

Oil roller chains on auger drive and cross conveyor

drive. Oil through slots provided in the chain shields.

Oil or grease HI-LO range brass shifting collar.

BEGINNING OF CROP MAINTENANCE

(approximately 100-150 loads)

Grease main shaft bearings.

Grease range control sleeve.

Grease gear cluster shaft bearings.

Maintain oil levelin gear boxes. SeeL13, page 20.

Adjust range control per “Clutch Engagement”.

END OF CROP CLEANUP AND MAINTE

-

NANCE

Clean out all forage material from inside the box, roof,

and on the outside of the box. Clean the front cross

apron on the top and in the lower pan (chain return) area.

Clean out the deflector shield at the rear of the box, both

inside and outside.

New or used oil is recommended to be applied to the

floor and inside of the box walls. Also coat all apron

chains and slats with oil.

3200 & 4200 Series -- 24 –