Page 34

Defrost System

This section addresses:

S Emergency Heat

S Defrost System Overview

S Defrost Control Connections, Jumper Settings and

Features

S Operational Mode Overview (Calibration, Normal and

Defrost)

S Defrost Cycle Actuation

EMERGENCY HEAT (AMBER LIGHT)

An emergency heat function is designed into some room

thermostats. This feature is applicable when isolation of the

outdoor unit is required, or when auxiliary electric heat is

staged by outdoor thermostats. When the room thermostat is

placed in the emergency heat position, the outdoor unit

control circuit is isolated from power and field-provided relays

bypass the outdoor thermostats. An amber indicating light

simultaneously comes on to remind the homeowner that he

is operating in the emergency heat mode.

Emergency heat is usually used during an outdoor unit

shutdown, but it should also be used following a power

outage if power has been off for over an hour and the

outdoor temperature is below 50°F (10°C). System should

be left in the emergency heat mode at least six hours to

allow the crankcase heater sufficient time to prevent

compressor slugging.

DEFROST SYSTEM OVERVIEW

The control monitors ambient temperature, outdoor coil

temperature, and total run time to determine when a

defrost cycle is required. The coil temperature probe is

designed with a spring clip to allow mounting to the outside

coil tubing. The location of the coil sensor is important for

proper defrost operation.

NOTE − The demand defrost control accurately measures

the performance of the system as frost accumulates on the

outdoor coil. This typically will translate into longer running

time between defrost cycles as more frost accumulates on

the outdoor coil before the demand defrost control initiates

defrost cycles.

DEFROST CONTROL CONNECTIONS, JUMPERS

SETTINGS AND FEATURES

Pressure Switch 5−Strike Lockout

The internal control logic of the demand defrost control

counts the pressure switch trips only while the Y1 (Input)

line is active. If a pressure switch opens and closes four

times during a Y1 (Input), the control logic will reset the

pressure switch trip counter to zero at the end of the Y1

(Input). If the pressure switch opens for a fifth time during

the current Y1 (Input), the control will enter a lockout

condition.

The 5−strike pressure switch lockout condition can be reset

by cycling OFF the 24−volt power to the demand defrost

control or by shorting the TEST pins between 1 to 2

seconds. All timer functions (run times) will also be reset.

If a pressure switch opens while the Y1 Out line is

engaged, a 5−minute short cycle will occur after the switch

closes.

Demand Defrost Control Pressure Switch

Connections

The unit’s automatic reset pressure switches (LO PS − S87

and HI PS − S4) are factory−wired into the demand defrost

control on the LO−PS and HI−PS terminals, respectively.

Demand Defrost Control Sensors

Sensors connect to the demand defrost control through a

field-replaceable harness assembly that plugs into the

demand defrost control as illustrated in figure 1. Through

the sensors, the demand defrost control detects outdoor

ambient, coil, and discharge temperature fault conditions.

As the detected temperature changes, the resistance

across the sensor changes.

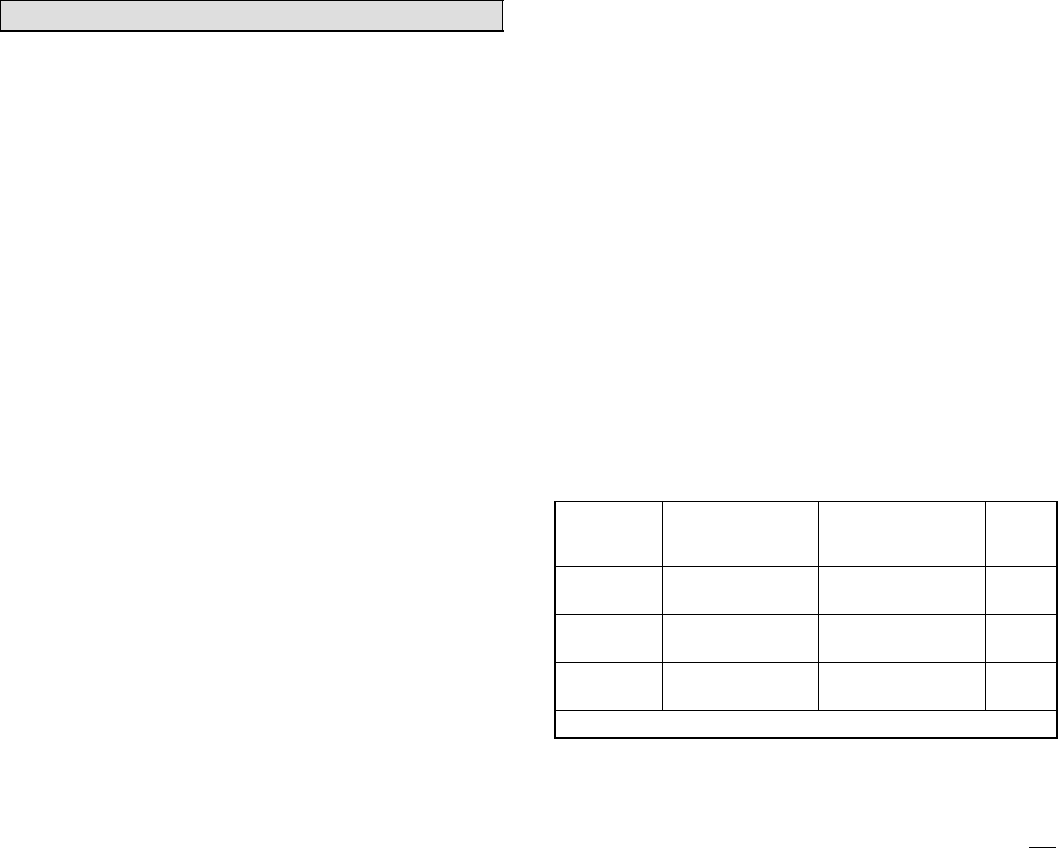

Testing Demand Defrost Control Sensors

Sensor resistance values can be checked by ohming

across pins shown in table 11.

Table 11. Sensor Temperature /Resistance Range

Sensor

Temperature

Range °F (°C)

Resistance values

range (ohms)

Pins/W

ire

Color

Outdoor −35 (−37) to 120 (48) 280,000 to 3750 3 & 4

(Black)

Coil −35 (−37) to 120 (48) 280,000 to 3750 5 & 6

(Brown)

Discharge (if

applicable)

24 (−4) to 350 (176) 41,000 to 103 1 & 2

(Yellow)

Note: Sensor resistance increases as sensed temperature decreases.

Tables 12 and 13 shows how the resistance varies as the

temperature changes for various types of sensors.

NOTE − When checking the ohms across a sensor, be

aware that a sensor showing a resistance value that is not

within the range shown in table 11, may be performing as

designed. However, if a shorted or open circuit is detected,

then the sensor may be faulty and the sensor harness will

need to be replaced.

Defrost Temperature Termination Jumper

Settings (P1)

The demand defrost control selections are: 50, 70, 90, and

100°F (10, 21, 32 and 38°C). The shunt termination pin is

factory set at 50°F (10°C). If temperature shunt is not

installed, default termination temperature is 90°F (32°C).

Test Pins (P1) Function

Placing the jumper on the field test pins (P1) allows the

technician to:

S Clear short cycle lockout

S Clear five−strike fault lockout

S Cycle the unit in and out of defrost mode

S Place the unit in defrost mode to clear the coil

See figure 27 for flowchart of test pin (P1) operations.