Page 32

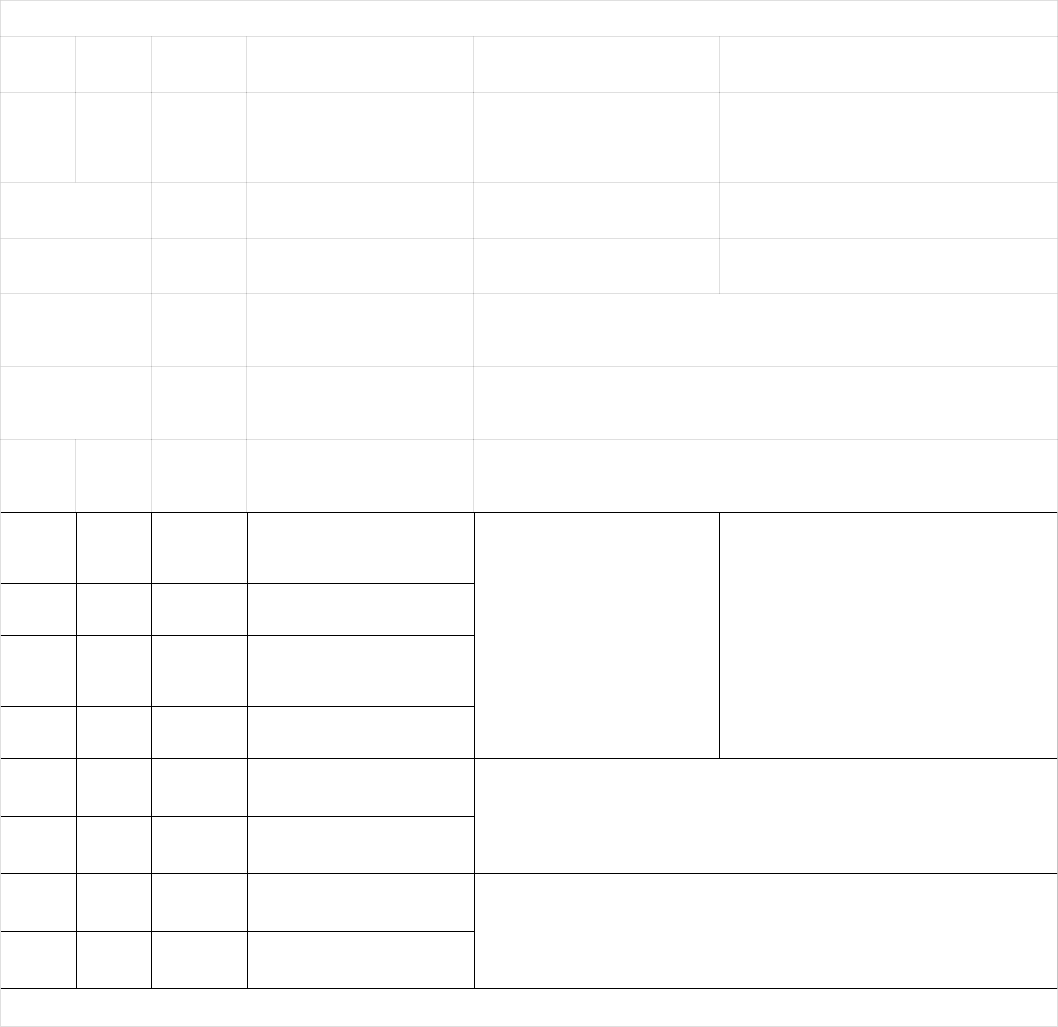

DEMAND DEFROST CONTROL (A108) DIAGNOSTIC LEDS

The state (Off, On, Flashing) of two LEDs on the demand defrost control (DS1 [Red] and DS2 [Green]) indicate diagnostics

conditions that are described in table 10.

Table 10. Demand Defrost Control (A108) Diagnostic LEDs

DS1 and DS2 System Status, Fault and Lockout Codes

DS2

Green

DS1

Red

Type

Condition/Code Possible Cause(s) Solution

OFF OFF Status Power problem

No power (24V) to demand

defrost control terminals R and C

or demand defrost control failure.

1

Check control transformer power (24V).

2

If power is available to demand defrost con-

trol and LED(s) do not light, replace demand

defrost control.

Simultaneous

SLOW Flash

Status Normal operation

Unit operating normally or in

standby mode.

None required.

Alternating SLOW

Flash

Status 5−minute anti−short cycle delay

Initial power up, safety trip, end of

room thermostat demand.

None required (jumper TEST pins to override)

Simultaneous

FAST Flash

Fault Ambient Sensor Problem

Sensor being detected open or shorted or out of temperature range. Demand defrost

control will revert to time/temperature defrost operation. (System will still heat or

cool).

Alternating

FAST Flash

Fault Coil Sensor Problem

Sensor being detected open or shorted or out of temperature range. Demand defrost

control will not perform demand or time/temperature defrost operation. (System will

still heat or cool).

ON ON Fault

Demand Defrost Control

Failure

Indicates that demand defrost control has internal component failure. Cycle 24VAC

power to demand defrost control. If code does not clear, replace demand defrost

control.

OFF

SLOW

Flash

Fault Low Pressure Fault

1

Restricted air flow over indoor or

outdoor coil.

2

Improper refrigerant charge in

system.

3

Improper metering device

installed or incorrect operation

of metering device.

4

Incorrect or improper sensor

location or connection to

system.

1

Remove any blockages or restrictions from

coils and/or fans. Check indoor and outdoor

fan motor for proper current draws.

2

Check system charge using subcooling

method.

3

Check system operating pressures and

compare to unit subcooling tables in this

instruction or located on unit access panel.

4

Make sure all pressure switches and sensors

have secure connections to system to prevent

refrigerant leaks or errors in pressure and

temperature measurements.

OFF ON Lockout Low Pressure Lockout

SLOW

Flash

OFF Fault High Pressure Fault

ON OFF Lockout High Pressure Lockout

SLOW

Flash

ON Fault

Discharge Line Temperature

Fault

This code detects shorted sensor or high discharge temperatures. If the discharge

line temperature exceeds a temperature of 285ºF (140ºC) during compressor

operation, the demand defrost control will de−energize the compressor contactor

output (and the defrost output if active). The compressor will remain off until the

discharge temperature has dropped below 225ºF (107ºC).

FAST

Flash

ON Lockout

Discharge Line Temperature

Lockout

OFF

Fast

Flash

Fault Discharge Sensor Fault

The demand defrost control detects open sensor or out of temperature sensor range.

This fault is detected by allowing the unit to run for 90 seconds before checking

sensor resistance. If the sensor resistance is not within range after 90 seconds, the

demand defrost control will count one fault. After 5 faults, the demand defrost control

will lockout.

Fast

Flash

OFF Lockout

Discharge Sensor Lockout

(Each fault adds 1 strike to that code’s counter; 5 strikes per code = LOCKOUT)