Page 25

XC16 SERIES

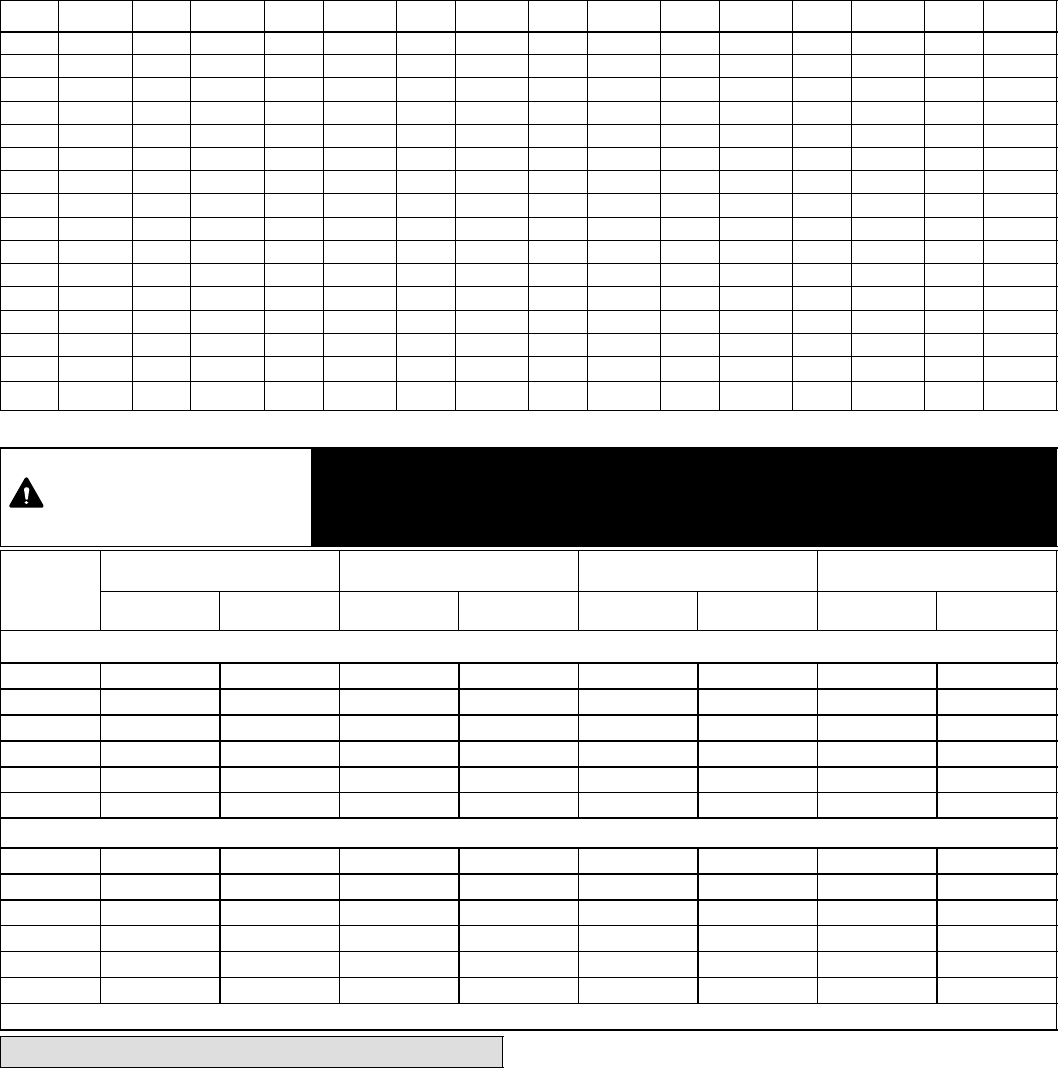

Table 3. HFC−410A Temperature (°F) − Pressure (Psig)

°F

Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig °F Psig

32 100.8 48 137.1 63 178.5 79 231.6 94 290.8 110 365.0

125 445.9

141 545.6

33 102.9 49 139.6 64 181.6 80 235.3 95 295.1 111 370.0 126 451.8 142 552.3

34 105.0 50 142.2 65 184.3 81 239.0 96 299.4 112 375.1 127 457.6 143 559.1

35 107.1 51 144.8 66 187.7 82 242.7 97 303.8 113 380.2 128 463.5 144 565.9

36 109.2 52 147.4 67 190.9 83 246.5 98 308.2 114 385.4 129 469.5 145 572.8

37 111.4 53 150.1 68 194.1 84 250.3 99 312.7 115 390.7 130 475.6 146 579.8

38 113.6 54 152.8 69 197.3 85 254.1 100 317.2 116 396.0 131 481.6 147 586.8

39 115.8 55 155.5 70 200.6 86 258.0 101 321.8 117 401.3 132 487.8 148 593.8

40 118.0 56 158.2 71 203.9 87 262.0 102 326.4 118 406.7 133 494.0 149 601.0

41 120.3 57 161.0 72 207.2 88 266.0 103 331.0 119 412.2 134 500.2 150 608.1

42 122.6 58 163.9 73 210.6 89 270.0 104 335.7 120 417.7 135 506.5 151 615.4

43 125.0 59 166.7 74 214.0 90 274.1 105 340.5 121 423.2 136 512.9 152 622.7

44 127.3 60 169.6 75 217.4 91 278.2 106 345.3 122 428.8 137 519.3 153 630.1

45 129.7 61 172.6 76 220.9 92 282.3 107 350.1 123 434.5 138 525.8 154 637.5

46 132.2 62 175.4 77 224.4 93 286.5 108 355.0 124 440.2 139 532.4 155 645.0

47 134.6 78 228.0 109 360.0 140 539.0

Table 4. Normal Operating Pressures (Liquid +10 and Suction +5 psig)

IMPORTANT

Use this table to perform maintenance checks; it is not a procedure for charging the

system. Minor variations in these pressures may be due to differences in installations.

Significant deviations could mean that the system is not properly charged or that a

problem exists with some component in the system.

Temp. of air

entering

outdoor coil

5F (5C)

−024 −036 −048 −060

Liquid Suction Liquid Suction Liquid Suction Liquid Suction

First Stage (Low Capacity)

65 (18.3) 215 144 226 142 224 142 215 136

75 (23.9) 247 146 261 144 258 144 250 139

85 (29.4) 288 148 304 145 299 146 291 142

95 (35.0) 332 151 352 147 345 148 337 144

105 (40.6) 381 153 405 150 395 150 388 146

115 (46.1) 435 155 460 150 450 153 444 148

Second Stage (High Capacity)

65 (18.3) 225 140 228 144 235 135 220 130

75 (23.9) 258 142 262 146 269 137 256 133

85 (29.4) 301 144 306 148 313 139 299 136

95 (35.0) 346 146 353 150 361 141 347 138

105 (40.6) 397 149 405 151 412 143 402 141

115 (46.1) 452 151 462 154 471 146 462 143

*These are typical pressures only. Indoor indoor match up, indoor air quality, and indoor load will cause the pressures to vary.

System Operation

TWO−STAGE COMPRESSOR

The two−stage scroll compressor operates much like the

standard scroll compressor. The two−stage compressor

steps between low capacity and high capacity as required

to meet cooling demand. The steps occur when gas is

bypassed through a vent port in the first suction pocket.

This bypassing of gas allows the compressor to operate at

low capacity if thermostat demand allows, creating a more

cost effective and efficient compressor.

Full capacity is achieved by blocking the vent port with a

slider ring. The slider ring (vent port cover) is controlled by

a 24VDC internal solenoid in the open position allowing low

capacity. When energized the internal solenoid closes the

slider ring, blocking the vent port and bringing the

compressor to full capacity. Stepping can occur during a

single thermostat demand as the motor runs continuously

while the compressor steps from low to full capacity.