icomfortt Touch Screen 7−Day Programmable Thermostat

Page 33

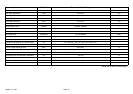

Alarm Codes and Troubleshooting

Alarm ID Action required to Clear/RecoverMessage Name

241 Flame Out of Sequence − Still Present Shut off gas, check for gas valve leak.

250 Primary Limit Switch Open Check firing rate on furnace, blockage in heater, and air flow.

252 Discharge Air Temperature High Check temperature rise, air flow and input rate.

270 Watch Guard − Flame Failure on Ignite Check for gas flow, ignitor lighting burner, flame sensor current.

271 Watch Guard − Low Pressure Switch Open Check inches of water column closing pressure of low pressure switch on heat call, measure inches of water

column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction.

272 Watch Guard − Low Pressure Switch Open Run

Mode

Check operation of low pressure switch for stuck closed on heat call, measure inches of water column of oper-

ating pressure, inspect vent and combustion air inducer for correct operation and restriction. Check inches of

water column closing pressure of high pressure switch on heat call, measure inches of water column of operat-

ing pressure, inspect vent and combustion air inducer for correct operation and restriction.

273 Watch Guard − Flame Fail in Run Mode Check micro amperes of flame sensor in board diagnostics or field installed mode; clean or replace sensor.

Measure voltage of neutral to ground for good unit ground.

274 Watch Guard − Primary Limit Switch Open Check why limit is tripping, over fired, low air flow.

275 Watch Guard − Flame Out of Sequence. No

Flame

Shut off gas, check for gas valve leak.

276 Watch Guard − Calibration Failure Unable to perform pressure switch calibration. Check vent system and pressure switch wiring connections.

290 Ignition Circuit Problem Measure resistance of Hot Surface Ignition ignitor, replace if open or not within specification; otherwise replace

control.

291 Heat Airflow Restricted Below Min. Check for dirty filter, unit air flow restriction, blower performance.

292 Indoor Blower Motor Start Problem Indoor blower motor unable to start (seized bearing, stuck wheel, etc.). Replace motor or wheel if assembly

does not operate or meet performance.

294 Inducer Motor Over current Check combustion blower bearings, wiring, amps. Replace if does not operate or meets performance.

295 Indoor Blower Over Temperature Indoor blower motor over temperature (motor tripped on internal protector). Check motor bearings, amps; re-

place if necessary.

310 Discharge Air Sensor Problem Compare outdoor sensor resistance to temperature/resistance charts in installation instructions. Replace sensor

if necessary.

311 Heat Rate Reduced to Match Airflow Furnace blower in cutback mode due to restricted airflow. Check filter and ductwork. To clear, replace filter if

needed or repair/add ductwork.

312 Reduced Airflow − Indoor Blower Cutback Restricted airflow − Indoor blower is running at a reduced CFM (Cutback Mode − The variable speed motor has

pre−set speed and torque limiters to protect the motor from damage caused by operating out of its designed

parameters (0 to 0.8" w.g. total external static pressure). Check filter and ductwork. To clear, replace filter if

needed or repair/add ductwork.

table continued on next page