506052−01 11/09

Page 32

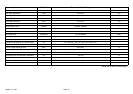

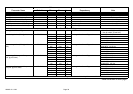

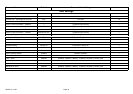

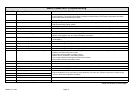

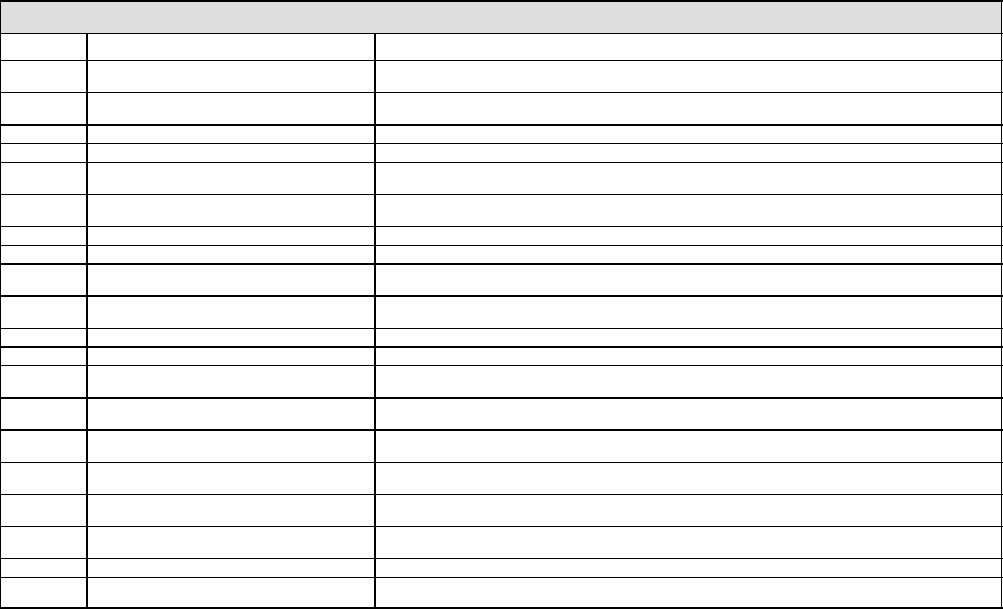

Alarm Codes and Troubleshooting

Alarm ID Action required to Clear/RecoverMessage Name

125 Control Hardware Problem Hardware problem on the control board. Cycle power on control. Replace if problem prevents service and is

persistent.

126 Control Internal Communication Problem Hardware problem on the control board. Cycle power on control. Replace if problem prevents service and is

persistent.

130 Configuration Jumper Missing Configuration jumper(s) missing on control board (applicable in non−communication only).

131 Corrupted Control Parameters Reconfigure the system. Replace board if service (heating cooling) is not viable.

132 Failed Flash CRC Check (Check Sum) Software

is corrupted.

Recycle power, if re−occurs replace control.

180 Outdoor Temperature Sensor Problem Compare outdoor sensor resistance to temperature/resistance charts in installation instructions. Replace if

necessary.

200 Rollout Limit Switch Open Correct unit cause of rollout trip or replace flame rollout switch and test furnace operation.

201 Indoor Blower Motor Problem Indoor blower communication failure including power outage. Check wiring to motor.

202 ID Blower Motor & Unit Size Mismatch Incorrect appliance capacity code selected. Check for proper configuring under: Unit Size Codes for Furnace/Air

Handler on configuration guide or in installation instructions.

203 Invalid Unit Code No appliance capacity code selected. Check for proper configuring under: Unit Size Codes for Furnace/Air

Handler on configuration guide or in installation instructions.

204 Gas Valve Problem Check operation and wiring of gas valve.

205 Gas Valve Relay Contact Closed Check wiring to relay; if wiring is correct, replace relay.

207 HSI Sensed Open Measure resistance of Hot Surface Ignition ignitor. Replace if open or not within specification range found in

IOM.

223 Low Pressure Switch Open Check inches of water column closing pressure of low pressure switch on heat call, measure inches of water

column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction.

224 Low Pressure Switch Stuck Closed Check operation of low pressure switch for stuck closed on heat call, measure inches of water column of oper-

ating pressure, inspect vent and combustion air inducer for correct operation and restriction.

225 High Pressure Switch Failed to Close Check inches of water column closing pressure of high pressure switch on heat call, measure inches of water

column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction.

226 High Pressure Switch Stuck Closed Check operation of high pressure switch for closing on heat call, measure inches of water column of operating

pressure, inspect vent and combustion air inducer for correct operation and restriction.

227 Low Pressure Switch Open in Run Mode Check inches of water column closing pressure of low pressure switch on heat call, measure inches of water

column of operating pressure, inspect vent and combustion air inducer for correct operation and restriction.

228 Inducer/Pressure Switch Calibration Failure Unable to perform pressure switch calibration. Check vent system and pressure switch wiring connections.

240 Low Flame Current − Run Mode Check micro amperes of flame sensor in board diagnostics or field installed mode; clean or replace sensor.

Measure voltage of neutral to ground for good unit ground.

table continued on next page