8

6 - CONNECTING SUPPLY AND RETURN PIPING

WARNING

Burn and scald hazard. Safety relief valve could

discharge steam or hot water during operation. In-

stall discharge piping per these instructions.

!

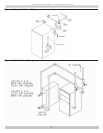

Figure 3 - Temperature Pressure Gauge

Verify clean water supply is available to water inlet

valve. Install sand strainer when water supply is from

a well or pump.

Install hot water boiler above radiation level or as

required by Authority having jurisdiction install low

water cutoff device at time of installation. Periodic

inspection is necessary, as is fl ushing of fl oat type

devices, per manufacturers specifi c instruction.

FOR USE WITH COOLING UNITS

A. Boiler used in connection with refrigeration

system, must be installed so that chilled medium

is piped in parallel with heating boiler. Appropriate

valves must be used to prevent chilled medium

from entering heating boiler. See Figure 5 page 9.

B. Boiler connected to heating coils located in air

handling units where they may be exposed to

refrigerated air circulation, piping system shall

be equipped with fl ow control valves or other

automatic means to prevent gravity circulation of

boiler water during cooling cycle.

LOW WATER TEMPERATURE AND LARGE WATER

CONTENT SYSTEM (See Figures 6 and 7, Page 10.)

Signifi cant condensation may form in boiler and/or

venting system if boiler is operated for long period of

time with return temperatures of less than 120° F.

Condensate is corrosive and can cause severe

damage to boiler and venting system. Minimum

design return water temperature to prevent

condensation in boiler and venting is 120°F.

Minimum high limit setting is 140°F.

1.

Boiler used in heating system where design water

temperatures below 140°F are desired (e.g. radiant

fl oor heating), 4-way mixing valve or suitable

alternative is required to prevent low temperature

return water from entering boiler. Follow mixing valve

manufacturer’s instructions.

2.

Boiler connected to system having large water content

(such as former gravity system), install system bypass.

See Figures 6 and 7, page 10.

3.

If boiler water reset control is used to operate boiler,

minimum reset supply water temperature setpoint

must be at least 140°F, unless mixing valve is used as

in (1) above.

1.

Boiler is shipped assembled. Install discharge piping

from safety relief valve. See Warning, Page 7.

2.

Install temperature pressure gauge.

• Apply pipe sealant to threads on shaft of gauge.

• Thread gauge into supply water tee. See Figure 3.

NOTICE

DO NOT TIGHTEN GAUGE BY HAND!! Gauge should

be tightened using crescent wrench or 9/16” open

end wrench. See Figure 3.

3.

Connect supply and return lines to boiler. Connections

may require additional fi ttings and parts, as shown on

diagrams.