Inches (mm)

Front View

[

34

9

_,EXHAUST

I '10" VENT

= _ NOTE -Enclosed ex_us_ pipe _s

insuleted w;th _F2 i,_Ch(13 ram)

INTAKE foam insu_abon If in_al(ear_ ex-

VENT hsusl I_pes am reversed, sl=land

r_move foam instJlat_ot_ and

Ii teat)ply to OUmr vent Exhaust

vent mr=st be insulated

Side View

4

USTVENT

o

iNTAKE

VENT

E

VENT TERMINATIONS

MODEL WTKX (30GT9)

EXTENSION RISER FOR GRADE CLEARANCE

FIGURE 19

G32Q VENTING IN EXISTING CHIMNEY

NOTE -Do not dischal_e exhaust gases ditently into or vent stack.

II ventCal discharge through at, ex_6ng unused chimney or stack ts require<J,

i_sertpipingintgde chlm,'.eyurdilthe pipeopenendIsabovetopof _y and

termimlte as iltusttstad. I. any extedor po(tlon of ¢ilrmney, the exhaust vent must

be insulated.An alternatemethodistoflitthechimneywithvetrmc.ulitoorequal

to take advantage of its acoustic and thermal properties,

FIGURE 20

Condensate Piping

This unit is designed for either right- or left-side exit of

condensate piping. Route the condensate drainiine only

within the conditioned space: this prevents possible

freezing of the condensate, which would block the drain-

line. Use an electric heat cable if you route the conden-

sate line through unconditioned areas.

A CAUTION

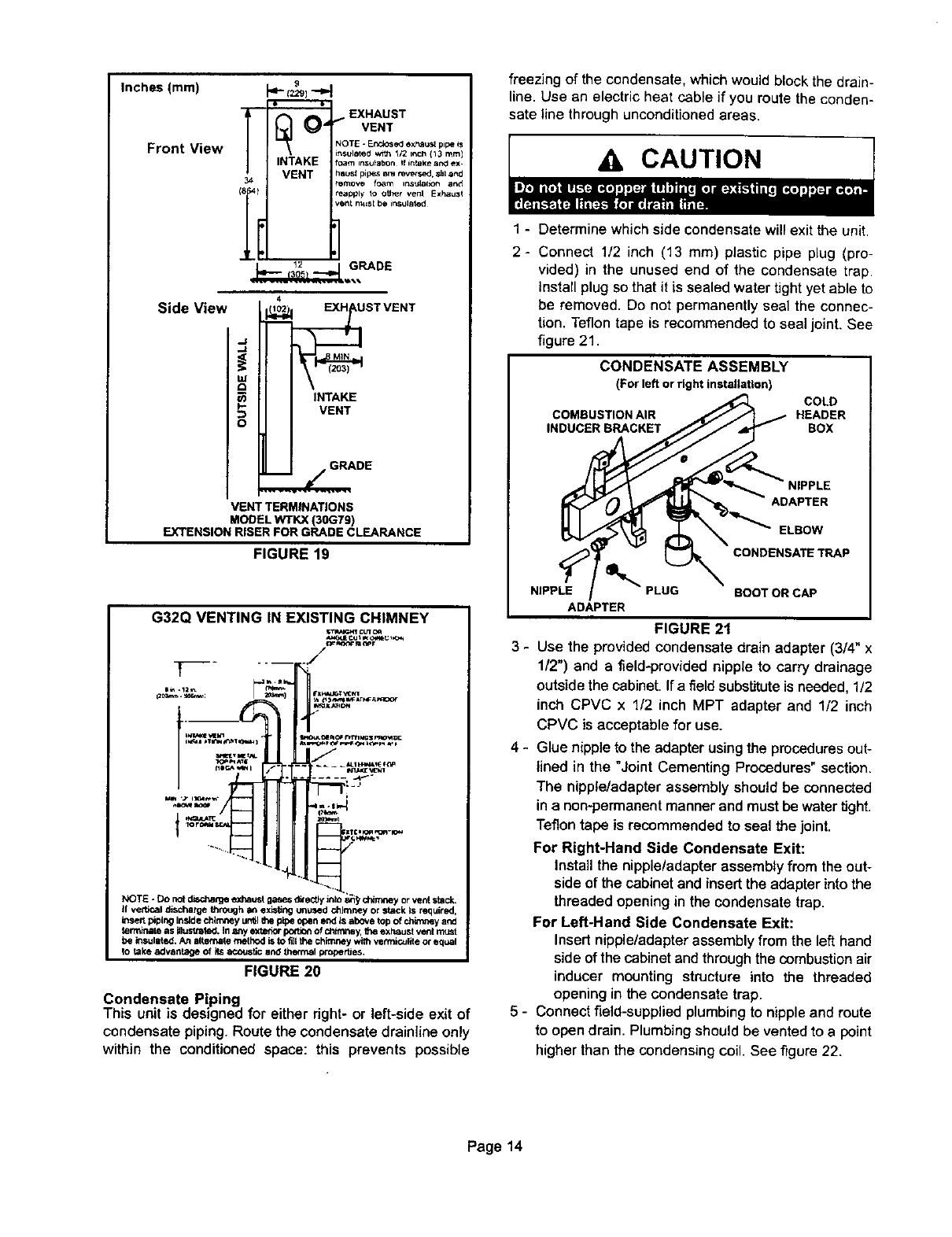

1 - Determine which side condensate will exit the unit.

2- Connect 1/2 inch (13 mm) plastic pipe plug (pro-

vided) in the unused end of the condensate trap.

Install plug so that it is sealed water tight yet able to

be removed. Do not permanently seal the connec-

tion. Teflon tape is recommended to seal joint. See

figure 21.

CONDENSATE ASSEMBLY

(Forleftor rightinstallation)

COLD

COMBUSTION AIR HEADER

INDUCER BRACKET BOX

ADAPTER

ELBOW

CONDENSATE TRAP

NIPPLE BOOTORCAP

ADAPTER

FIGURE 2t

3 - Use the providedcondensate drain adapter (3/4" x

1/2") and a field-providednipple to carry drainage

outside the cabinet. If a fieldsubstitute is needed, 1/2

inch CPVC x 1/2 inch MPT adapter and 1/2 inch

CPVC is acceptable for use.

4 - Glue nipple to the adapter using the procedures out-

lined in the "Joint Cementing Procedures" section.

The nipple/adapter assembly should be connected

in a non-permanentmanner and must be water tight.

Teflon tape is recommended to seal the joint.

For Right-Hand Side Condensate Exit:

Install the nipple/adapter assembly from the out-

side of the cabinet and insert the adapter intothe

threaded opening in the condensate trap.

For Left-Hand Side Condensate Exit:

Insert nipple/adapterassemblyfrom the left hand

side of the cabinet and through the combustion air

inducer mounting structure into the threaded

opening in the condensate trap.

5 - Connect field-supplied plumbing to nipple and route

to open drain. Plumbing should be vented to a point

higher than the condensing coil. See figure 22.

Page14