Page 27

1 − Seal any unused openings in the common venting sys-

tem.

2 − Inspect the venting system for proper size and horizontal

pitch. Determine that there is no blockage, restriction,

leakage, corrosion, or other deficiencies which could

cause an unsafe condition.

3 − Close all building doors and windows and all doors be-

tween the space in which the appliances remaining

connected to the common venting system are located

and other spaces of the building. Turn on clothes dry-

ers and any appliances not connected to the common

venting system. Turn on any exhaust fans, such as

range hoods and bathroom exhausts, so they will oper-

ate at maximum speed. Do not operate a summer ex-

haust fan. Close fireplace dampers.

4 − Follow the lighting instructions. Turn on the appliance

that is being inspected. Adjust the thermostat so that

the appliance operates continuously.

5 − After the main burner has operated for 5 minutes, test

for leaks of flue gases at the draft hood relief opening.

Use the flame of a match or candle.

6 − After determining that each appliance connected to the

common venting system is venting properly, (step 3)

return all doors, widows, exhaust fans, fireplace damp-

ers, and any other gas−burning appliances to their pre-

vious mode of operation.

7 − If a venting problem is found during any of the preced-

ing tests, the common venting system must be modi-

fied to correct the problem.

Resize the common venting system to the minimum

vent pipe size determined by using the appropriate

tables in Appendix G. (These are in the current stan-

dards of the National Fuel Gas Code ANSI Z223.1.

Electrical

ELECTROSTATIC DISCHARGE (ESD)

Precautions and Procedures

CAUTION

Electrostatic discharge can affect electronic com-

ponents. Take precautions during furnace installa-

tion and service to protect the furnace’s electronic

controls. Precautions will help to avoid control ex-

posure to electrostatic discharge by putting the fur-

nace, the control and the technician at the same

electrostatic potential. Neutralize electrostatic

charge by touching hand and all tools on an un-

painted unit surface, such as the gas valve or blower

deck, before performing any service procedure.

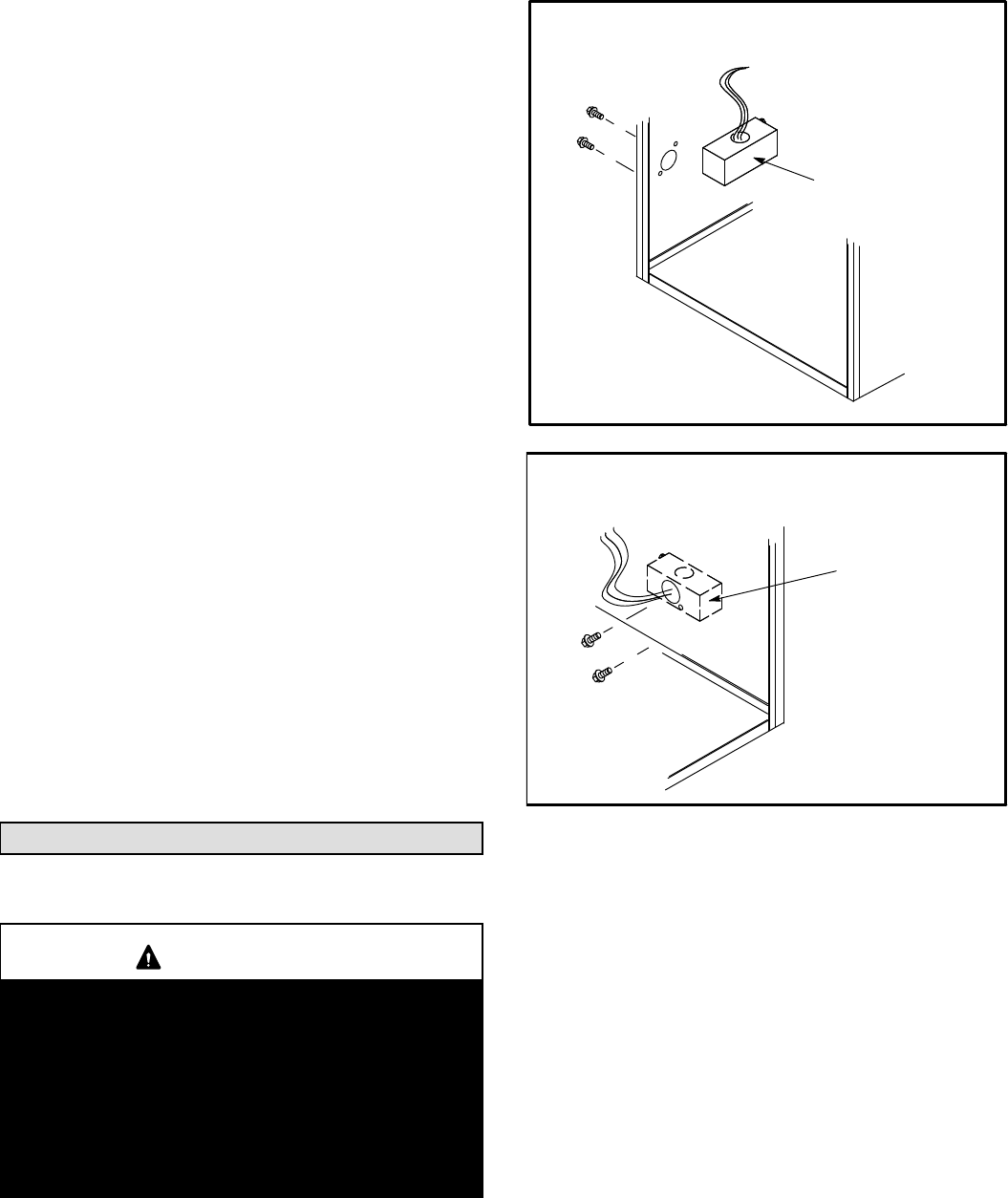

FIGURE 38

MAKE−UP

BOX INSIDE

CABINET

Left side

INTERIOR MAKE−UP BOX

(FACTORY− INSTALLED LEFT SIDE)

FIGURE 39

MAKE−UP

BOX

OUTSIDE

CABINET

Right Side

EXTERIOR MAKE−UP BOX

(FIELD PROVIDED RIGHT SIDE)

The unit is equipped with a make−up box on the left hand

side of the cabinet. A field−provided make−up box can be

installed on the exterior of the right side of the furnace to

facilitate installation. If the make−up box is moved to the

right side, clip the wire ties that bundle the wires together

and install on the outside of the cabinet. See figure 39. The

excess wire must be pulled into the blower compartment.

Secure the excess wire to the existing harness to protect it

from damage.

Refer to figure 40 for unit field wiring. See figures 41 and 42

for icomfort Toucht thermostat wiring in communicating

applications. Table 14 shows DIP switch and on−board link

settings for non−communicating thermostat applications.

Typical wiring schematic is shown in figure 43.