10 NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE

14.0 CHECKING THE BURNER

There are no imitation fuel bed components, such as logs or rocks,

to install. The appliance features a ribbon burner which is designed to

produce a continuous band of flame over its length. The burner should

be visually inspected to ensure it is free from any foreign matter. If it is

necessary to clean or dust off the burner then the glass door should be

removed by removal of the four retaining screws. Re-fit the glass door

after cleaning or inspection, ensuring a good seal.

15.0 CONNECTING A GAS LINE

A qualified gas appliance installer must connect the gas room heater to

the gas supply. Consult all local codes.

The installer must provide an ANSI approved manual shut off valve, flex

connector and 3/8" NPT fitting. A flex gas line kit with shut-off valve is

available (see Page 16 or ordering information).

Route gas line using techniques and materials prescribed by local

and/or national codes. Only use pipe of 1/2" or greater size to allow full

gas volume to the gas fireplace. Undue pressure loss will occur if the

pipe is too small.

An external regulator must be used on all propane (L.P.G.) heaters, in

addition to the regulator fitted to the heater, to reduce the supply tank

pressure to 13" w.c. (maximum).

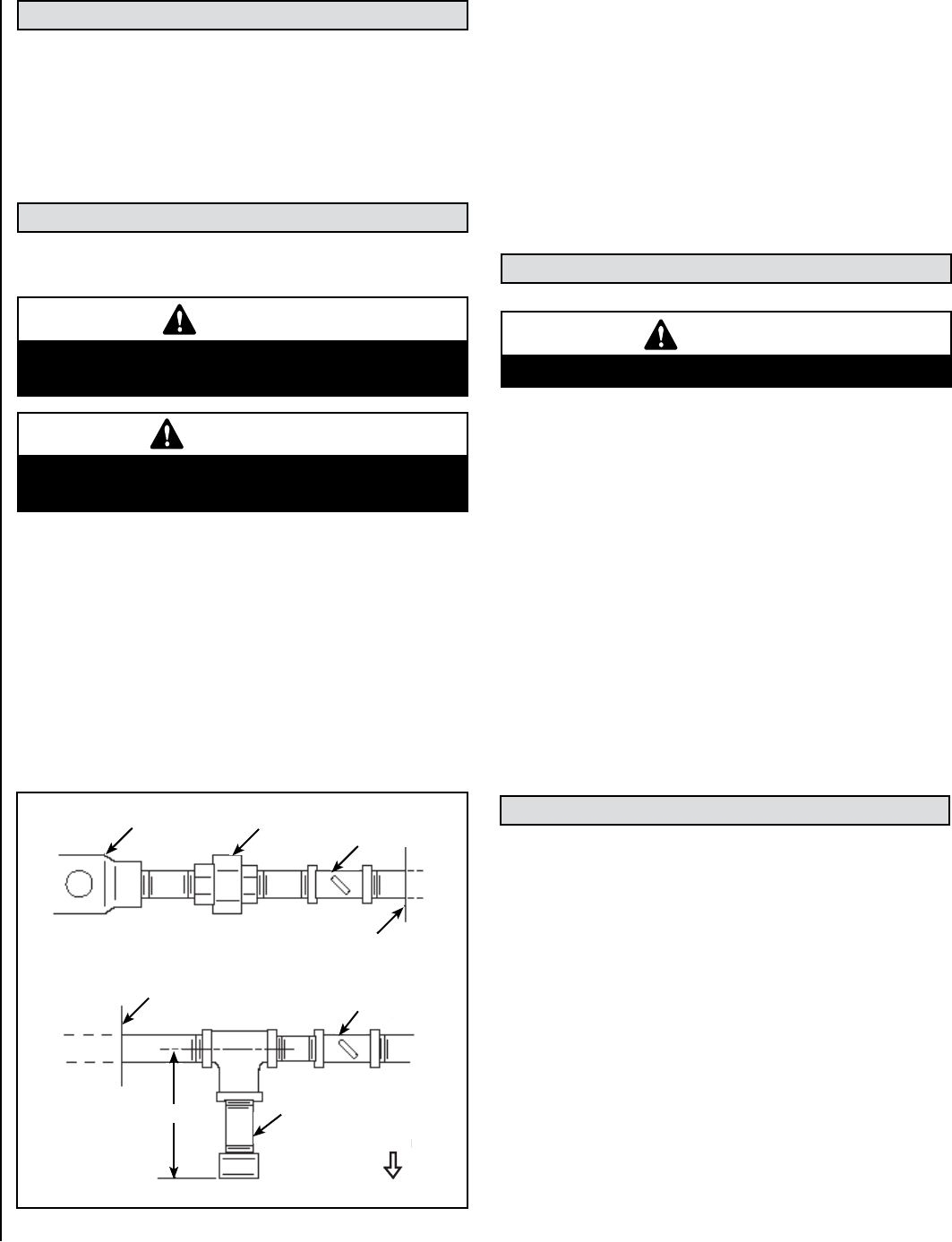

Regulator

Manual

Shut-Off

Valve

Union

Sediment

Trap

Fireplace or

Firebox Wall

Wall

Shut-Off

Key

Fireplace or

Firebox Wall

Down

3"

Figure 6

WARNING

Connecting directly to a unregulated propane (L.P.G.)

tank may cause an explosion.

An ANSI approved manual shut-off valve and union must be installed

upstream of the heater within the fireplace cavity when rigid pipe is

used. Ensure that a sediment trap is installed upstream of the heater

(Figure 4) within the structure’s piping system to prevent moisture

and contaminants from passing through the pipe to the heater controls

and burner. Failure to do so could prevent the heater from operating

reliably.

The heater gas inlet connection is 3/8” NPT at the regulator, located

below the burner, in the right hand side of the heater. When tightening

up the joint to the regulator hold the regulator securely with a wrench

to prevent the regulator from moving.

IMPORTANT

Hold heater regulator with a wrench to prevent move-

ment when connecting to inlet piping.

16.0 CHECKING THE GAS CONNECTIONS

Turn on gas supply and test for gas leaks using a gas leak test solution

(also referred to as bubble leak solution).

NOTE: Using a soapy water solution (50% dish soap, 50% water) is

an effective leak test solution, but it is not recommended, because the

soap residue that is left on the pipes/fittings can result in corrosion

over time.

A. Light the appliance (refer to the lighting instructions label in the control

compartment or on Page 14).

B.

Brush all joints and connections with the gas leak test solution to

check for leaks. If bubbles are formed, or gas odor is detected, turn

the gas control knob (off/pilot/on) to the “OFF” position. Either tighten

or refasten the leaking connection, then retest as described above.

C.

When the gas lines are tested and leak free, be sure to rinse off the

leak testing solution.

D.

Observe the individual tongues of flame on the burner. Make sure all

ports are open and producing flame evenly across the burner. If any

ports are blocked, or partially blocked, clean out the ports.

17.0 GAS PRESSURE CHECK

WARNING

Never use an open flame to check for leaks.

Checking Manifold Pressure at Provided Test Point (see Figure 7a) -

The pressure test point is located on the left hand side of the appliance,

on the main burner pipe, next to the brass restrictor adjacent to the

front left hand side burner bracket. Release the setting pressure test

point screw, and attach a U gauge. Light the fire on the HIGH setting.

Checking Manifold and Inlet Pressure at Valve (see Figure 7b) - The

heater regulator controls the burner pressure which can be checked at

the pressure test points located on the control valve itself for burner

(manifold) and regulator (inlet) setting pressures.

The valve is located on the lower right side of the appliance (see

exploded view drawing on Page 17). Release the test point screws and

ensure operating pressures are as specified in Table 1 on Page 3 of

these instructions. The pressure should be checked with the gas heater

burning and the control set to high flame.

NOTE: See Page 19 for gas line entry point dimensions.