12

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

1. If not previously installed, install floor protection and move the

heater into the desired location.

2. Position the stove on your floor protection in the exact location

where it is to be located, making sure all minimum clearances are

met.

3. If you are installing outside air on your stove, mark a 4” circle on

the floor protection just below the oblong ring. When cut out, this

hole will accommodate the flexible outside air tube.

4. If the stove is to be fastened to the floor, locate the hold down

brackets inside the leg box and mark the floor protection below the

holes in the brackets.

5. If you are installing outside air on your stove, remove the stove and

cut the floor protection and the floor where the 4” air tube circle had

been previously drawn. If the stove is to be fastened to the floor,

drill 1/2” holes through the floor protection only, at the marks that

were for fastening the stove to the floor if so desired. Slip the flexible

outside air tube through the hole in the floor, leaving 1” of tube above

the floor protector surface, using tape to hold it in place.

6. Place the stove on the floor protection so that the previously cut or

drilled holes line up. Attach the stove to the floor with the lag bolts

if so desired.

7. If you are installing outside air on your stove, place the hose clamp

over the flexible air tube and slide the tube up over the 4” ring on

the outside air adaptor box and tighten the hose clamp. Push the

outside air adaptor forward 1/4” until full contact is made with the

lower heatshield. Tighten the 1/4” bolt until the adaptor box is held

firmly in place. Use silicone sealant to create a seal between the

flexible air tube and your floor protection.

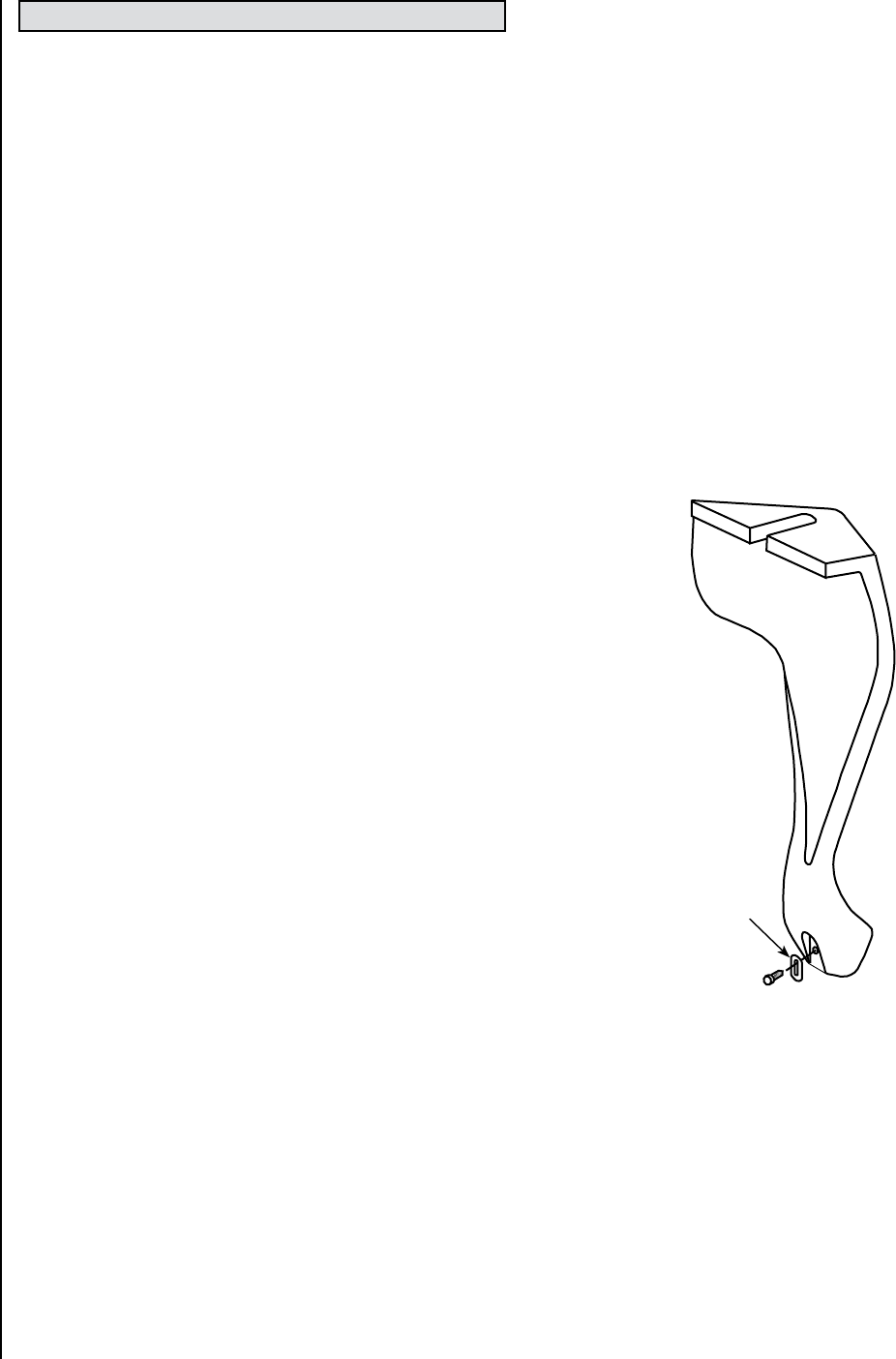

8. If it is necessary to level, secure, or ground your stove, use the holes

in the bottom of the leg for those applications. To level the stove

on Olympic cast legs, locate the front leg that is not touching the

hearth pad. Insert the allen head screw through the slotted washer

(supplied with the legs) and into the threaded hole in the bottom of

the leg. See the drawing to the right. Push the slotted washer down

until it touches the hearth pad and then tighten the screw into the

leg. Should any other leg not be resting on the hearth pad, install a

washer and screw in that leg as well.

9. Install bricks and baffle as per instructions on Pages 14 and 15.

It is highly recommended that the baffle be assembled before the

chimney is installed so that the baffle blankets can be adjusted into

place through the flue collar.

10. If installed into a mobile home, the stove shall be grounded to the

mobile home chassis with a #8 AGW copper wire or equivalent.

11. For residential installations, install the first section of stove pipe

with the crimped end going down inside the flue collar on the heater.

Continue with your stove pipe, installing each section-crimped

end down. Make the final connection to your chimney. Your dealer

carries the necessary pipe and fittings to connect to the various

listed factory-built chimneys. YOUR CHIMNEY INSTALLATION MUST

COMPLY WITH LOCAL BUILDING AND FIRE CODES.

12. Be sure to fasten each stove pipe connection with at least 3 sheet

metal screws.

13. Install chimney as per manufacturer’s instructions. Some brands of

pipe may require removal of the spacer ring in the flue collar.

14. All horizontal runs of pipe should be as short as possible and are

required by NFPA No. 211 to have an upward pitch or rise in the same

direction the smoke travels of no less than 1/4” to the linear foot.

The connector pipe must meet minimum clearances in any direction

to walls or other combustible materials. It must attach to a listed

double wall metal chimney at least 6” in diameter or to a masonry

chimney with a flue passage of at least 48 square inches.

15. It is required that a chimney connector pipe not extend further than

the inner wall of the flue when it is connected to a masonry chimney

and that it either be cemented to the masonry or be installed without

cement in a thimble connected to the masonry wall. When the

connector is inserted into a thimble, the joint must be tight enough

so that it will not be dislodged in normal use. Install connector at

no less than the minimum clearances from the ceiling when using

a 90-degree elbow to pass through combustible constructions.

16. Chimney connector pipes should never pass through a floor, ceiling,

fire wall, partition, or combustible construction of any type unless

certain precautions are taken. The best method is to use a listed

thimble and a listed chimney in accordance with the manufactures

directions. NFPA No. 211 gives approved methods for passing a

flue pipe through combustible constructions.

Figure 12

STOVE INSTALLATION

Insert the allen

head screw

through the

slotted washer