11

NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

vent installation

Venting:

The Vision™ gas stove has been tested and listed as a direct

vent heater system by OMNI-Test Laboratories, Beaverton,

Oregon and is recommended for use with Security™ Secure

Vent™ pipe*.

Important:

• Read all instructions carefully before starting the instal

-

lation. Failure to follow these instructions may create a

fire or other safety hazard, and will void the warranty.

Be sure to check for specific clearances to combustible

requirements on page 8.

Do not extend the venting sys-

tem vertically or horizontally in excess of the distance

prescribed on page 14. Consult your local building codes

before beginning the installation.

• Always maintain the proper air spaces between the

vent pipe and nearby combustibles to prevent a fire

hazard. Do not fill air spaces with insulation. Be sure to

check the vent termination clearance requirements from

decks, windows, soffits, gas regulators, air supply inlets,

and public walkways, as specified in these installation

instructions on page 15 and local building codes.

• This gas stove and vent system must be vented directly

to the outside of the building, and never be attached to

a chimney serving a separate solid fuel or gas-burning

appliance. Each direct vent gas appliance must use its

own separate vent system. Common vent systems are

prohibited.

• The Vision gas stove is recommended for use with

Security™ Secure Vent pipe*. The appliances, and vent

manufacturers warranties will be voided, and serious fire,

health, or other safety hazards may result from any of the

following actions:

• Installation of any damaged direct vent compo

-

nent.

• Unauthorized modification of the direct vent sys

-

tem.

• Installation of any vent component part not approved

or manufactured by the approved vent manufac

-

turer.

• Installation other than as instructed by Lennox Hearth

Products and vent manufacturers instructions.

residential and mobile home installations:

These are the minimum pieces required. Other parts may

be required for your particular installation.

Minimum Components for Horizontal Installation:

Horizontal Termination Kit which includes:

• 1 6-5/8”x 6” Black Pipe

• 1 Riser Vent Terminal

• 1 Wall Penetration Heat Shield (Wall Thimble) (2 pcs)

• 1 Decorative Wall Trim (black)

• 1 Tube Mill-Pac

• Screws

Optional Components:

• 45º Elbow

• Vinyl Siding Shield for Riser Vent Terminal

• Vent Guard

• Snorkel Termination (36”)

• Snorkel Termination (14”)

• Wall Penetration Heat Shield

Vent Considerations

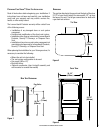

Twist-lock procedure: Four indentations on female ends of

pipes and fittings are designed to slide straight onto male

ends of adjacent pipes and fittings by orienting the four pipe

indentations so they match and slide into the four entry slots.

Push pipe sections completely together, then twist-lock one

section clockwise approximately one-quarter turn until the

two sections are fully locked. The female locking lugs will not

be visible from the outside on the pipe or fittings. They may

be located by examining the inside of the female ends.

Supports: Horizontal runs of vent must be supported every

3 feet. Wall straps are available for this purpose.

Pipe Sealing: If Simpson Dura-Vent pipe is used, the pipe

must be sealed as follows: seal both the inner and outer

pipes with a high temperature silicone sealant rated for at

least 600º F (commonly know as “RTV”). Run a 1/8” bead

of silicone around outside of male end of outer sleeve. Run

a 1/8” bead of silicone about 1/4” from the end of the male

inner pipe, which is found in the pipe to be attached above.

Twist-lock the pipes or fittings together.

Female Locking

Sealant

Male

Locking

Lugs

Figure 14