29

12. Is there a problem?

If something is not working, you can

use the table below to try and correct

the fault. If you are unable to remedy

the fault by yourself, please contact

Customer Service.

ƽ Warning!:

Before carrying out any maintenance

work on the sewing machine, first pull

the plug out of the power socket. This

will prevent the risk of accidents due to

the machine being started unintention-

ally.

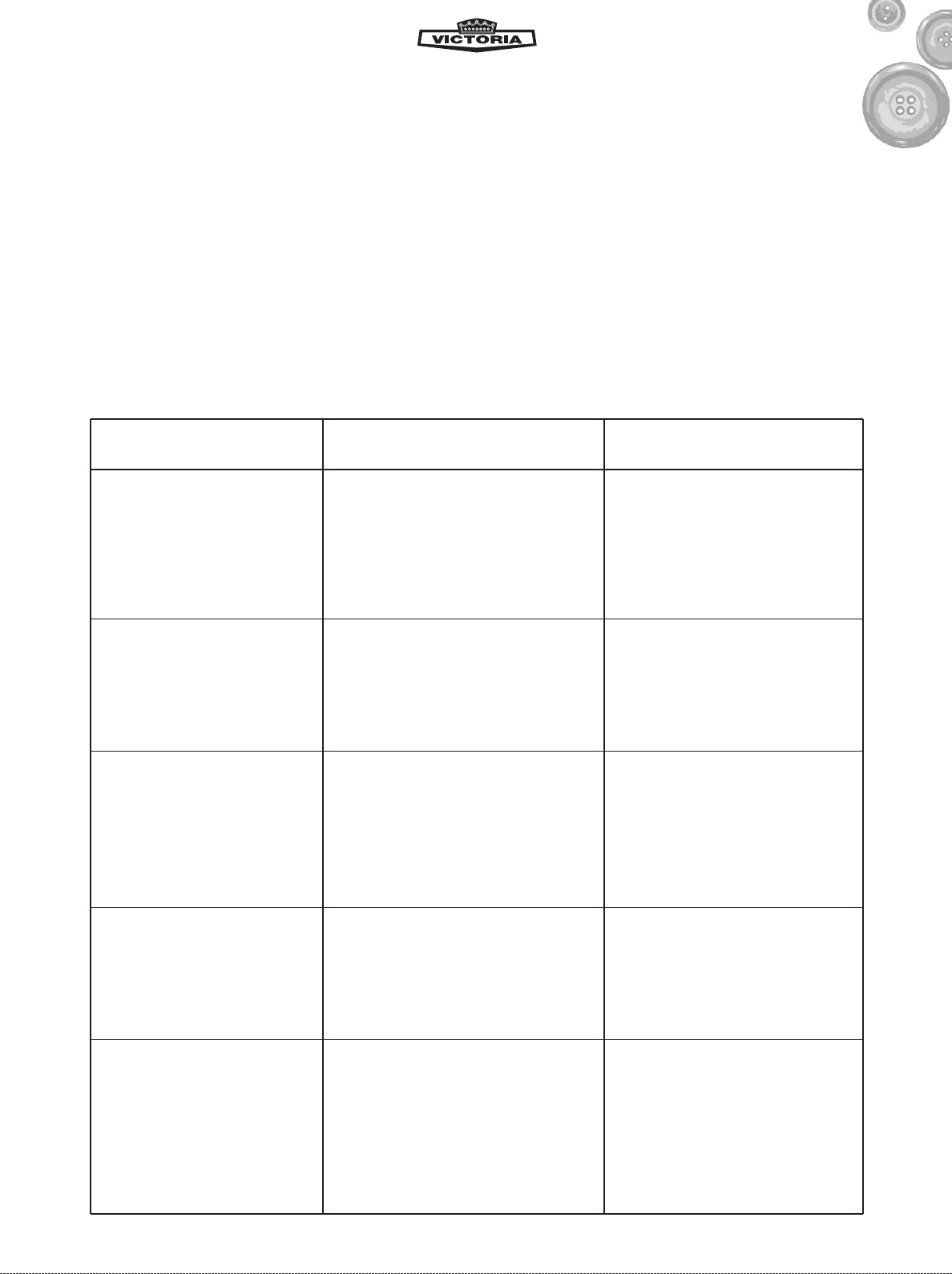

Fault / Problem: Check: Possible remedy:

Material is not moved through Machine does not sew – Press handwheel in!

Only the handwheel turns?

Stitch length wheel set to "0"? Set it at a value from "1“ to "4".

Presser pressure too weak? Set the pressure lever higher.

Needle breaks Needle set incorrectly? Set flat end towards the rear!

Needle is bent? Insert a new needle.

Are the needle + thread + material Select the correct needle for the

as in the Table in Chapter 10? thread and material.

The upper thread breaks Was it threaded correctly? It's best to re-thread from the

beginning!

Zigzag setting too wide? Try a smaller width.

Upper thread too taut? Select the middle setting.

Scoring / scratches on the gripper? Replace the gripper.

Lower thread breaks Lower thread too taut? Reduce the thread tension.

Needle set incorrectly? Set flat end towards the rear!

Was it threaded correctly? It's best to re-thread from the

beginning!

Dust and fluff in the gripper? Clean the gripper area

Ripples in the material Thread tension too high? Reduce the tension!

Foot pressure too high? Reduce the foot pressure!

Are the needle + thread + material Select the correct needle for the

as in the Table in Chapter 10? thread and material.

IB_Sewingmachine_content_UK.qxd 22.07.2004 12:21 Uhr Seite 29