- 5 -

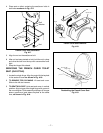

Old Style Flush Valve

Fig. #13

Trip Chain

Flush Ball

Flapper Hooks

Mounting Hooks

Screws

controls flow at various water pressures. An antiĆsiphon

valve prevents backflow.

For most satisfactory operation of this toilet, 25 to 80 psi

working pressure is required at the fixture. A full 1/2" supĆ

ply stop (K-7653) is recommended. A pressure regulaĆ

tor is recommend when pressure exceeds 125 psi.

The flush valve controls the flow of water from tank to bowl.

The flush ball and lift wire control valve operation at the end

of the flush. The lift wire provides for the accurate seating of

the flush ball.

BEFORE YOU BEGIN ADJUSTMENTS:

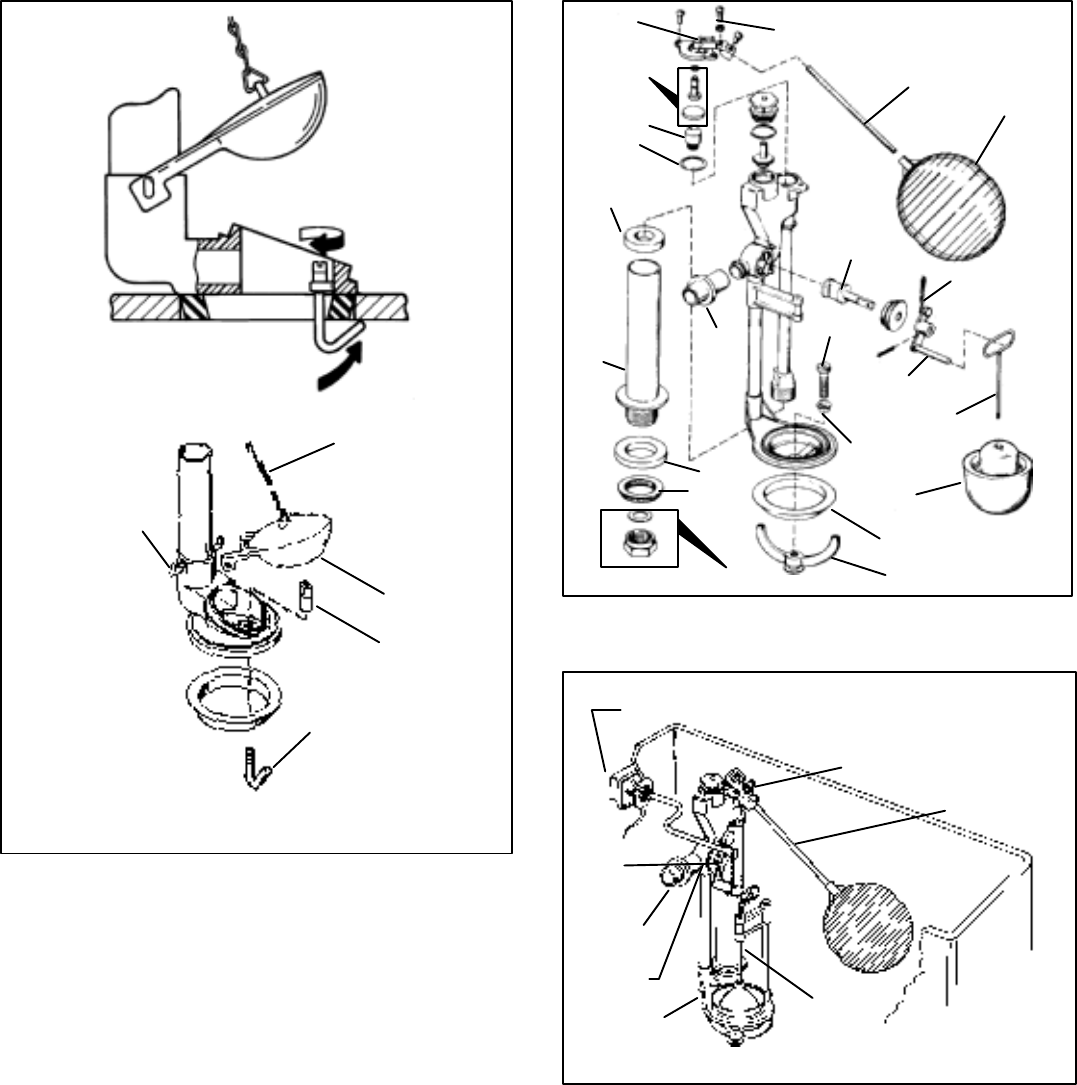

Refer to exploded view illustration (Fig. #14) and Fig.

#15. Make sure you understand the following before

you refer to the Troubleshooting Chart.

Rotor

Rochelle/Palarre Tank Fitting

Fig. #14

Float Ball

Float Rod

Adjusting Screw

Plunger S.A.

Seat

O-ring

Supply Connection

Lift Wire

Rotor Arm

Lift Chain

Hush

Tube

Rubber Gasket

Flush Ball

Cap Assembly

Rim

Flush

Tube

Locknut

Gasket

Rubber Seat Gasket

Seat Clamp

Plastic Collar

Screw

Trip Lever Tank Fitting Assembly

Fig. #15

Volume Control

Trip Lever Assembly

Flush Valve

Lift Wire

Rotor

Directional

Valve

Rim Flush

Tube

Float Rod

S WATER LEVEL. The water level must be at the waterline

indicated at the back of the tank for proper flushing of

bowl. Bend float rod if necessary to obtain the proper

water level. The flush valve will not shut off if the water is

above the overflow. If any pressure variation occurs in

the supply line, adjust the water level when the water

pressure is at its highest point.