[ii:ii:ii:ii: i:ii:ii: i:ii:ii: i:i SECTION 5 Ii ii:ii: i:ii:ii: i:ii:ii: i:ii:ii]S E RVIC E TEC H. INFO RMATIO N

A. TROUBLESHOOTING

MANUAL ADVANCE REGENERATION CHECK

This check verifies proper operation of the valve

motor, brine tank fill, brine draw, regeneration flow

rates, and other controller functions. Always make

the initial checks, and the manual initiated diag-

nostics.

Notes:

The faceplate display must show a steady time (not

flashing). If an error code shows, first press the SE-

to enter the diagnostic display.

Press the ON / OFF-HOLD button and hold in for

3 seconds. *RECHARGE and Fill begin to flash

(or clean backwash begins, if set) as the softener

enters the fill cycle of regeneration. When FILL is

on steady, remove the brinewell cover and, using

a flashlight, observe fill water entering the tank.

*Note:

If the CLEAN feature is set to ON, a cleaning back-

wash (CLEAN and Bkwsh or Rinse flashes in the dis-

play, along with the minutes of the clean cycle re-

maining), precedes the recharge.

a. If water does not enter the tank, look for an ob-

structed nozzle, venturi, fill flow plug, brine tubing,

or brine valve riser pipe.

CYCLE FLOW RATES (GALLONS PER MIN.)

FILL (flow to salt storage tank) 0.3 (1.1 liters)

BRINING '} .16 (.61 liters)

BRINE RINSE l .12 (.45 liters)

BACKWASH (flow to drain) 1.8 (6.8 liters)

FAST RINSE 1.8 (6.8 liters)

E After observing fill, press the ON/OFF-HOLD

button to move the softener into brining. A slow

flow of water to the drain will begin. Verify brine

draw from the brine tank by shining a flashlight

into the brinewell and observing a noticeable

drop in the liquid level.

Note:

Be sure a salt bridge is not preventing water with

salt contact.

a. If the softener does not draw brine...

...nozzle and/or venturi dirty or defective. See

page 3- 2

...nozzle and venturi not seated properly on gasket.

See page 3-2

...restricted drain (check drain fitting and hose).

...defective nozzle and venturi seal. See page 3-2

...other inner valve defect (rotor seal, rotor & disc,

wave washer, etc.).

Note: If water system pressure is low, an elevated

drain hose may cause back pressure, stopping brine

draw.

_1_ Again press ON/OFF-HOLD to move the soft-

ener into backwash. Look for a fast flow of water

from the drain hose.

a. An obstructed flow indicates a plugged top dis-

tributor, backwash flow plug, or drain hose.

_ Press ON/OFF-HOLD to move the softener into

fast rinse. Again look for a fast drain flow. Allow

the softener to rinse for a few minutes to flush out

any brine that may remain in the resin tank from

the brining cycle test.

_To return the softener to service, press ON / OFF-

HOLD.

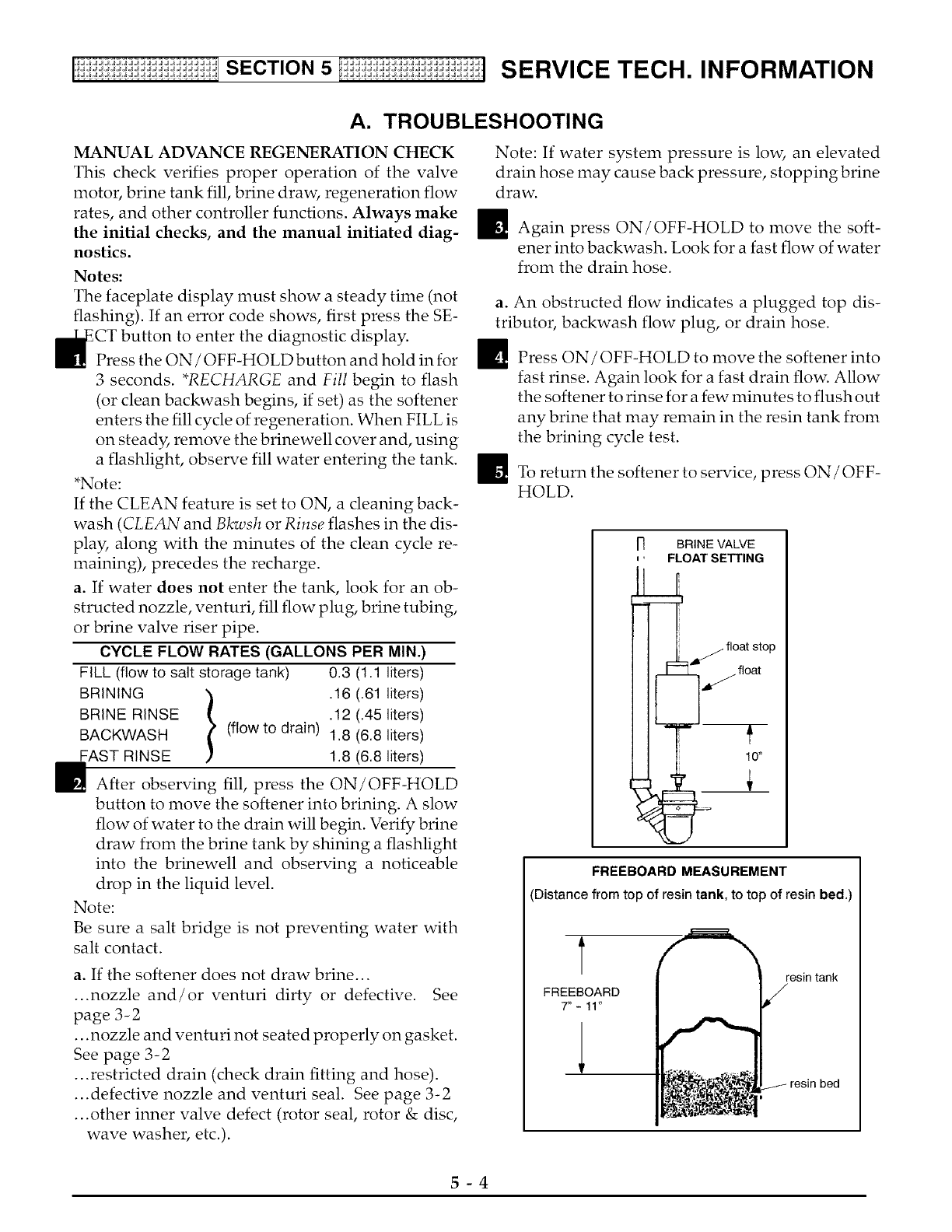

r] BRINE VALVE

, ' FLOAT SETTING

/. / float stop

float

FREEBOARD MEASUREMENT

Distance from top of resin tank, to top of resin bed.)

t

FREEBOARD

7"-11"

resin tank

5-4