18

TROUBLESHOOTING

Start Up Conditions

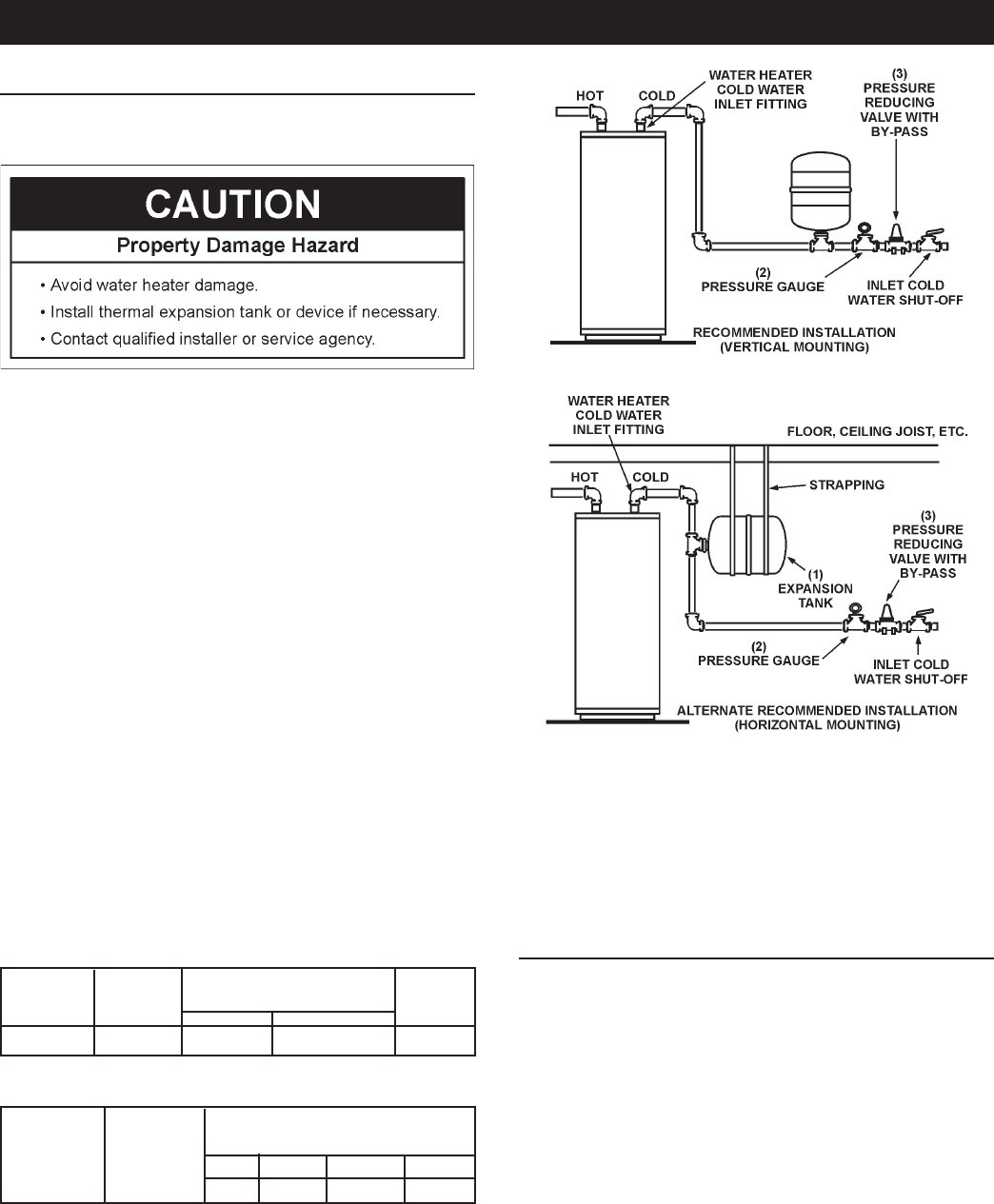

THERMAL EXPANSION

Water supply systems may, because of such events as high line

pressure, frequent cut-offs, the effects of water hammer among

others, have installed devices such as pressure reducing valves,

check valves, back ow preventers, etc...to control these types of

problems. When these devices are not equipped with an internal

by-pass, and no other measures are taken, the devices cause

the water system to be closed. As water is heated, it expands

(thermal expansion) and closed systems do not allow for the

expansion of heated water.

The water within the water heater tank expands as it is heated

and increases the pressure of the water system. If the relieving

point of the water heater’s temperature-pressure relief valve

is reached, the valve will relieve the excess pressure. The

temperature-pressure relief valve is not intended for the

constant relief of thermal expansion. This is an unacceptable

condition and must be corrected.

It is recommended that any devices installed which could create

a closed system have a by-pass and/or the system have an

expansion tank to relieve the pressure built by thermal expansion

in the water system. Thermal expansion tanks are available from

Sears stores and through the Sears Service Centers. Contact the

local plumbing inspector, water supplier and/or the Sears Service

Center for assistance in controlling these situations.

Thermal Expansion Tank Specications

Tank Dimensions Pipe

Model Capacity

in Inches Fitting

Number In Gallons Diameter Length On Tank

153.331020 2 8 (203 mm) 12-3/4 (323 mm) 3/4” Male

Expansion Tank Sizing Chart

Expansion Inlet* Water Heater Capacity (Gallons)

Tank Water

Capacity Pressure 6 10 20 30

Needed 40-80 psi 2 2 2 2

*Highest recorded inlet water pressure in a 24 hour period or

regulated water pressure.

NOTE: Expansion tanks are pre-charged with a 40 psi air

charge. If the inlet water pressure is higher than 40 psi, the

expansion tank’s air pressure must be adjusted to match

that pressure, but must not be higher than 80 psi.

FIGURE 29.

STRANGE SOUNDS

Possible noises due to expansion and contraction of some metal

parts during periods of heat-up and cool-down do not represent

harmful or dangerous conditions.

Operational Conditions

SMELLY WATER

In each glass-lined water heater there is installed one anode

rod (see parts section) for corrosion protection of the tank.

Certain water conditions will cause a reaction between this rod

and the water. The most common complaint associated with the

anode rod is one of a “rotten egg smell”. This odor is derived

from hydrogen sulde gas dissolved in the water. The smell is

the result of four factors which must all be present for the odor

to develop:

A. A concentration of sulfate in the supply water.

B. Little or no dissolved oxygen in the water.

C. A sulfate reducing bacteria within the water heater. (This

harmless bacteria is non-toxic to humans.)

D. An excess of active hydrogen in the tank. This is caused by

corrosion protective action of the anode.