10

Optional Installation Instructions

Some compact models have optional plumbing

connections. On these units, if top connection is

preferred over the side connection, use the following

instructions as they apply to your connection:

To change Temperature and Pressure (T&P) valve

location: Remove 3/4” plug from opening in jacket

top. Replace 3/4” plug opening with T&P valve;

plug original T&P valve opening with 3/4” plug. BE

SURE TO REAPPLY PIPE JOINT COMPOUND OR

TEFLON TAPE AROUND THE THREADED ENDS

OF THE TEMPERATURE AND PRESSURE (T&P)

VALVE AND THE 3/4” PLUG WHEN REINSTALLING

COMPONENTS.

To change Cold Inlet location: Remove 3/4” plug from

opening in jacket top. Replace 3/4” plug opening with

Cold Inlet nipple; plug original Cold Inlet opening with 3/4”

plug. BE SURE TO REAPPLY PIPE JOINT COMPOUND

OR TEFLON TAPE AROUND THE THREADED ENDS

OF THE COLD INLET NIPPLE AND THE 3/4” PLUG

WHEN REINSTALLING COMPONENTS.

To change Hot Outlet location: Screw 3/4” NPT galvanized

cap (not included, purchase locally) onto Side Hot Outlet

and install 3/4” NPT nipple (not included, purchase

locally) in the opening identified as HOT/T&P location.

BE SURE TO REAPPLY PIPE JOINT COMPOUND

OR TEFLON TAPE AROUND THE THREADED ENDS

OF THE 3/4” NPT NIPPLES WHEN REINSTALLING

COMPONENTS.

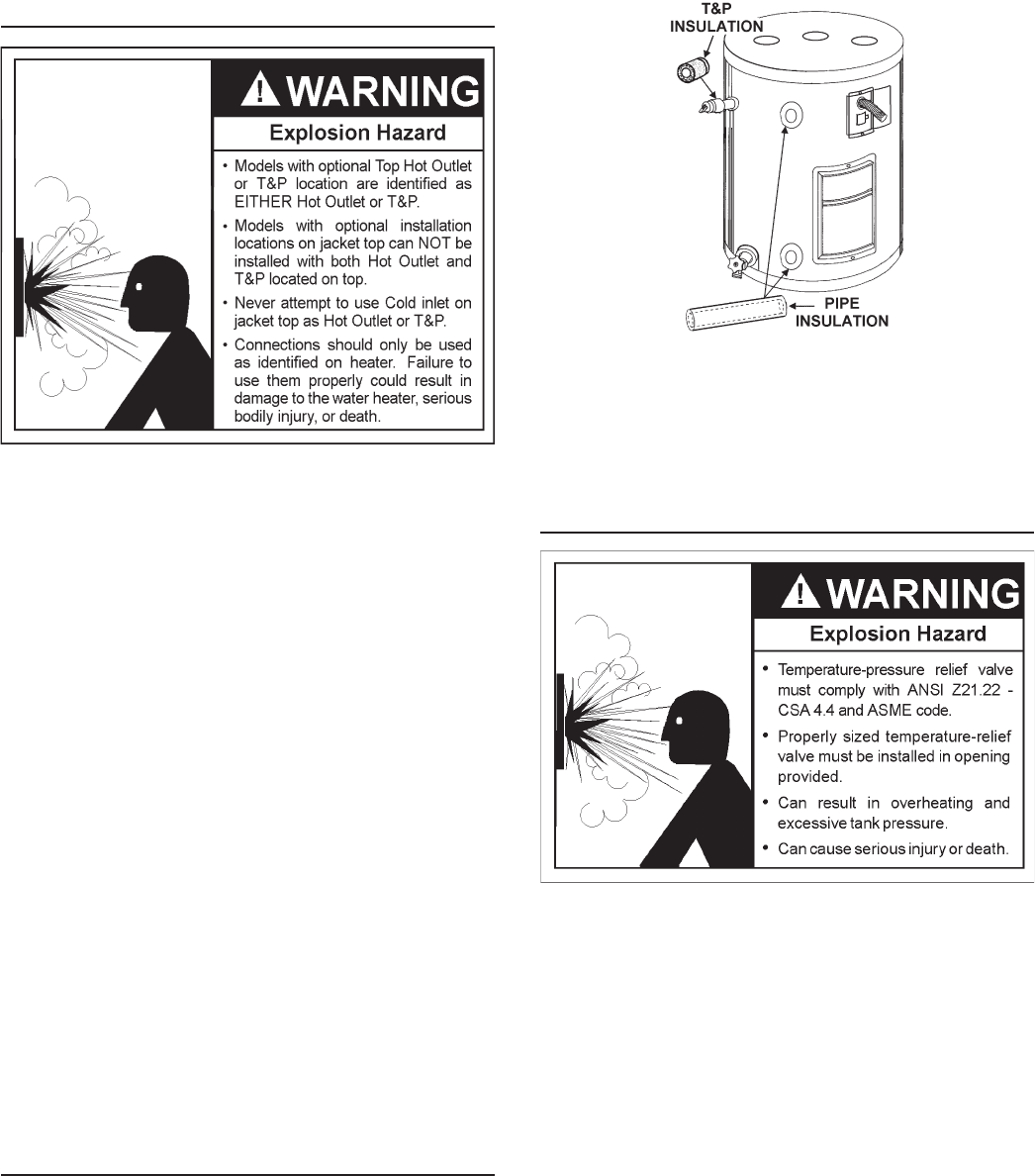

T & P Valve and Pipe Insulation

Remove insulation for T & P valve and pipe connections from

carton.

Fit pipe insulation over the incoming cold water line and the

hot water line. Make sure that the insulation is against the side

jacket of the heater.

Fit T & P valve insulation over valve. Make sure that the insulation

does not interfere with the lever of the T & P valve.

Secure all insulation using tape.

FIGURE 9A.

NOTE: Figure above is used to illustrate installation of

T&P and pipe insulation only. As indicated in PRODUCT

SPECIFICATION Section. Actual optional Cold & Hot / T&P

spud location vary from model to model.

Temperature-Pressure Relief Valve

This heater is provided with a properly certied combination

temperature - pressure relief valve by the manufacturer.

The valve is certied by a nationally recognized testing laboratory

that maintains periodic inspection of production of listed equipment

of materials as meeting the requirements for Relief for Hot

Water Supply Systems, ANSI Z21.22 • CSA 4.4, and the code

requirements of ASME.

If replaced, the valve must meet the requirements of local codes,

but not less than a combination temperature and pressure relief

valve certied as indicated in the above paragraph.

The valve must be marked with a maximum set pressure not to

exceed the marked hydrostatic working pressure of the water

heater (150 psi = 1,035 kPa) and a discharge capacity not less

than the water heater input rate as shown on the model rating

plate. (Electric heaters - watts x 3.412 equal Btu/hr input rate)

Your local jurisdictional authority, while mandating the use

of a temperature-pressure relief valve complying with

ANSI Z21.22 • CSA 4.4, may require a valve model different

from the one furnished with the water heater.

Compliance with such local requirements must be satised

by the installer or end user of the water heater with a locally