18

SECTION III - SCHEDULED MAINTENANCE AND SERVICING

WARNING / CAUTION

Before performing any maintenance procedure, make certain steam supply and electrical power

supply is OFF and cannot accidentally be turned on.

QUARTERLY INSPECTION

1. Monitor thermostat

a. Let water heater completely heat to a designated thermostat setting.

b. After thermostat satisfies (that is, when the thermostat actually clicks off), draw water from

heater.

c. Compare water temperature of drawn water to the temperature setting of the thermostat

when it satisfies. Normal variation between the two points is approximately + 5°F.

d. If these two readings do not coincide within acceptable tolerances and verification has

been made of the accuracy of the temperature-reading gauge, replace the thermostat.

2. Lift test lever on relief valve and let water run through valve for a period of approximately 10

seconds. This will help flush away any sediment that might build up in water passageways.

ANNUAL INSPECTION

1. Units subject to fouling or scaling should be cleaned periodically. A marked increase in

pressure drop and/or reduction in performance usually indicates cleaning is necessary.

2. To clean inside of tubes, remove all heads and covers. (Caution: Do not loosen heads until

you are sure all pressure is off the equipment, and the unit is drained).

3. In cleaning a tube bundle, tubes should not be hammered on. If it is necessary to use scrapers,

care should be taken to insure that the tubes are not damaged.

4. Before it is necessary to apply mechanical means for cleaning, try to clean the unit using the

following methods.

a. Circulate hot fresh water at a reasonable velocity.

b. Try spraying with water hose.

c. Consult with manufacturers of cleaning compounds and chemicals. They will check the

nature of the deposit, recommend the right cleaning compound, and in many cases

provide equipment and personnel for a complete cleaning job.

5. Do not clean tubes by blowing steam through individual tubes.

6. To tighten a loose tube joint, use a suitable roller type tube expander. Do not roll tubes that

are not leaking. If double wall tubes are supplied return to the factory for repairs.

7. If the unit is dismantled for any reason, it should be reassembled using new gaskets.

8. Do not tighten bolts until gaskets are properly seated.

9. Exterior of unit should be cleaned and if necessary repainted.

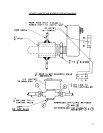

10. When tightening bolts in the element head, tighten the bolts in a criss-cross pattern. This will

evenly distribute pressure around the flange, and help prevent warping. See diagram below.