10

3. Stainless Steel – Stainless steel (type 304, 316, or 316L) is well suited for high purity

applications requiring a corrosion resistant tank with minimal leaching of impurities into the

water. Well suited for process, RO, and DI water systems in the pharmaceutical, food, and

electronic industries.

TANK CONNECTIONS

The heater is supplied with separate cold water and hot water connections. A connection is provided for

mounting a combination safety temperature and pressure relief valve. An overflow line should be

utilized from the relief valve outlet to a floor drain. See drawing for locations and sizes.

OUTER SHELL, INSULATION, AND SUPPORTS

The tank is encapsulated in 2-inches of high-density fiberglass insulation. The protective shell is

constructed of galvaneel and is coated with a durable silver hammertone finish. The entire vessel is

supported on heavy-duty integrally welded steel supports for sturdy floor mounting.

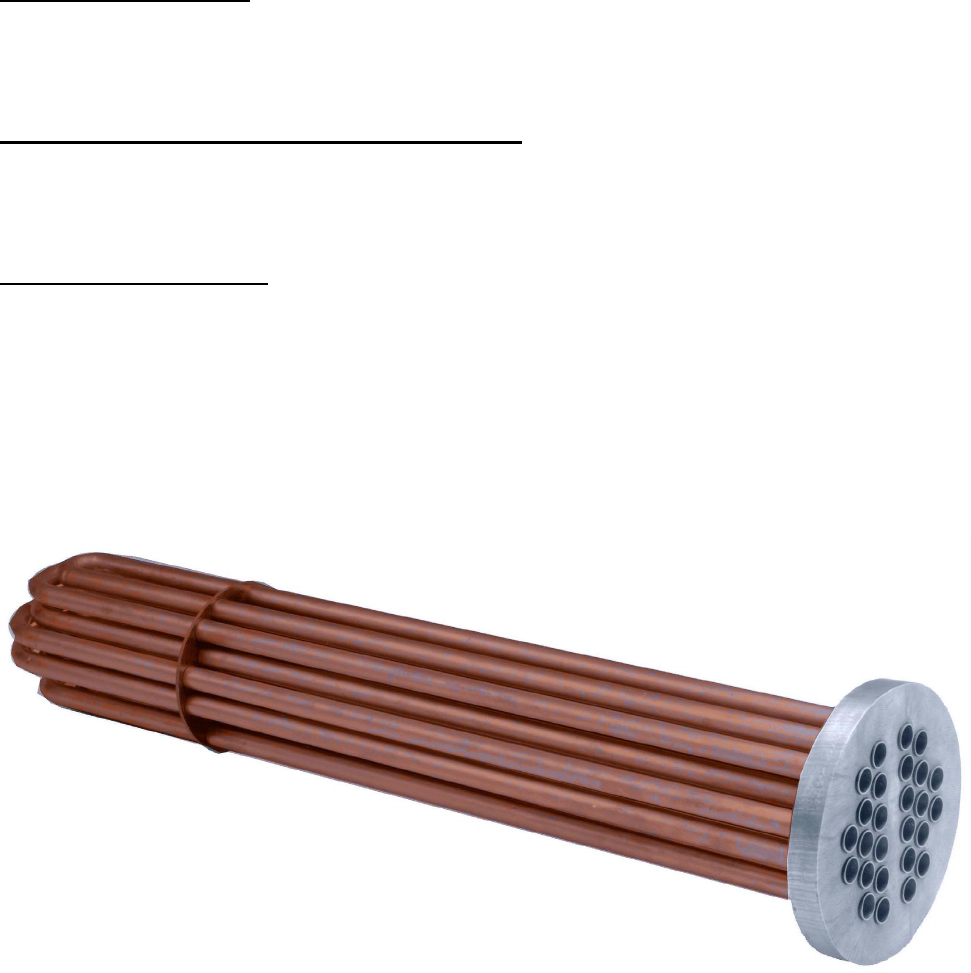

STEAM HEATING COIL

The water heater is supplied with a high quality factory installed 2-pass U-tube heating coil constructed

from 20-gauge ¾-inch O.D. single wall copper tubing designed for a maximum working pressure of

150 psi. The tubing is installed in a heavy-duty fabricated steel head with threaded NPT steam and

condensate connections. Each assembly is fastened to a corresponding tank flange using a gasket and

hex head steel bolts and nuts. Specialized heating coil construction may be included. These options

include: double wall tubing with a leak detection port, or special materials (stainless steel, 90/10

copper-nickel, other) for the tubes and/or head. See drawing for complete details.