CAUTION

23

Appendix: Installation

5.Air purging

Air and moisture remaining in the refrigerant system have

undesirable effects as indicated below. Therefore, they must be

purged completely.

pressure in the system rises

operating current rises

cooling efficiency drops

moisture in the air may freeze and block capillary tubing

water may lead to corrosion of parts in the refrigerant system

Air Purging with a Vacuum Pump (for Test Run)

(1)Check that each tube (both narrow and wide tubes between

the indoor and outdoor units have been properly connected

and all wiring for the test run has been completed. Note that

both narrow and wide tube service valves on the outdoor

unit are kept closed at this stage.

(2)Using an adjustable wrench or box wrench, remove the valve

caps from the service valve on both narrow and wide tubes.

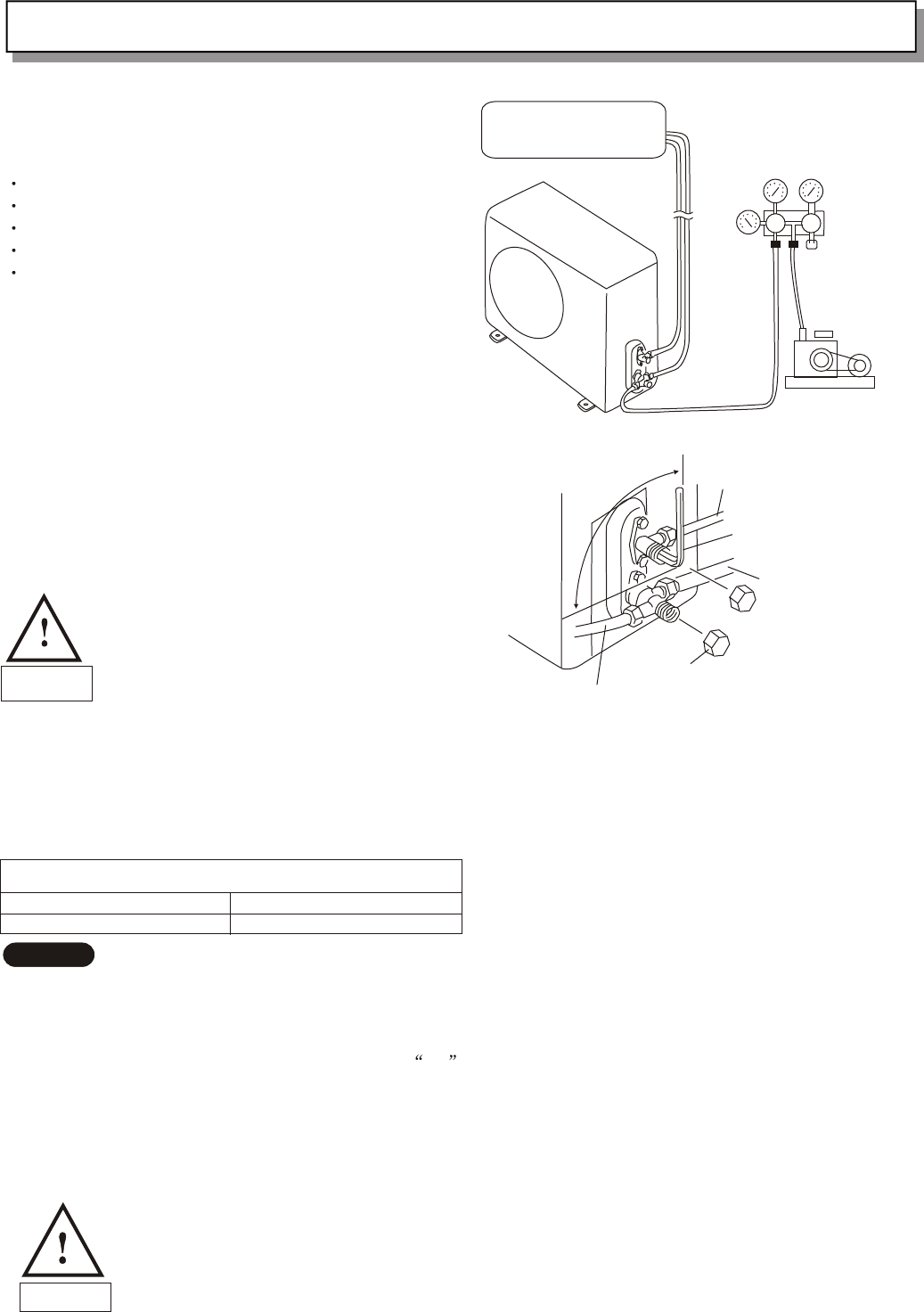

(3) Connect a vacuum pump and a manifold valve (with

pressure gauges) to the service port on the wide tube

service valve.(Fig.A)

CAUTION

Be sure to use a manifold valve for air

purging. If it is not available, use a

stop valve for this purpose. The ¡°Hi¡±

knob of the manifold valve must

always be kept closed.

(4)With the ¡°Lo¡±knob of the manifold valve open, run the vacuum

pump. The operation time for the vacuum pump varies with

tubing length and the capacity of the pump. The following table

shows the amount of time for evacuation:

Table

Required time for evacuation when capacity

of 100 liter/h vacuum pump is used

If tubing length is less than 10 m

10 min. or more

15 min. or more

If tubing length is more than 10 m

Be sure to completely insert the hex

wrench before attempting to turn the

valve.

The required time in the above table is calculated based

on the assumption that the ideal (or target) vacuum

condition is around 10 mmHg abs.

(5) With the vacuum pump still running, close the Lo

knob of the manifold valve. Then stop the vacuum

pump.

(6)With the accessory hex wrench, turn the valve stem on

the narrow tube service valve counterclockwise by 90

degrees (1/4 turn) for 10 seconds, and then turn the

stem clockwise to close it again. (Fig.B)

NOTENOTE

(7)Leak test all joints at the tubing (both indoor and outdoors)

with liquid soap. Bubbles indicate a leak. Be sure to wipe off

the soap with a clean cloth.

(8)With the hex wrench, turn the wide tube service valve stem

counter-clockwise to fully open the valve.

(9)Turn the narrow tube service valve stem counter-clockwise

to fully open the valve.

(10)Loosen the vacuum hose connected to the wide tube

service port slightly to release the pressure. Then, remove

the hose.

(11)Replace the bonnet and flare nut on the wide tube service

port and fasten the flare nut securely with an adjustable

wrench or box wrench. Next, mount the valve cap and

tighten it with a torque wrench (the cap needs to be

tightened with the torque of 200kg-cm). This process is

very important to prevent gas from leaking from the system.

(12)Test run the air conditioner.

(13)While the air conditioner is running, apply liquid soap to

check for any gas leaks around the service valves or caps.

(14)If there is no leakage, stop the air conditioner.

(15)Wipe off the soap on the tubing.

This completes air purging with a vacuum pump and

the air conditioner is ready for actual operation.

6. Please contact the technical service for further

information.

Vacuum pump

Indoor unit

Outdoor unit

Lo

Hi

Manifold valve

Pressure

gauge

90 (1/4 turn)

Narrow tube

Hex wrench

Wide tube

Valve cap

Vacuum hose to manifold valve

Fig.B

Fig.A