Min. 8mm

Thickness

of 8mm

Heat insulation materials

Tapered nuts

Copper tube

Flarer

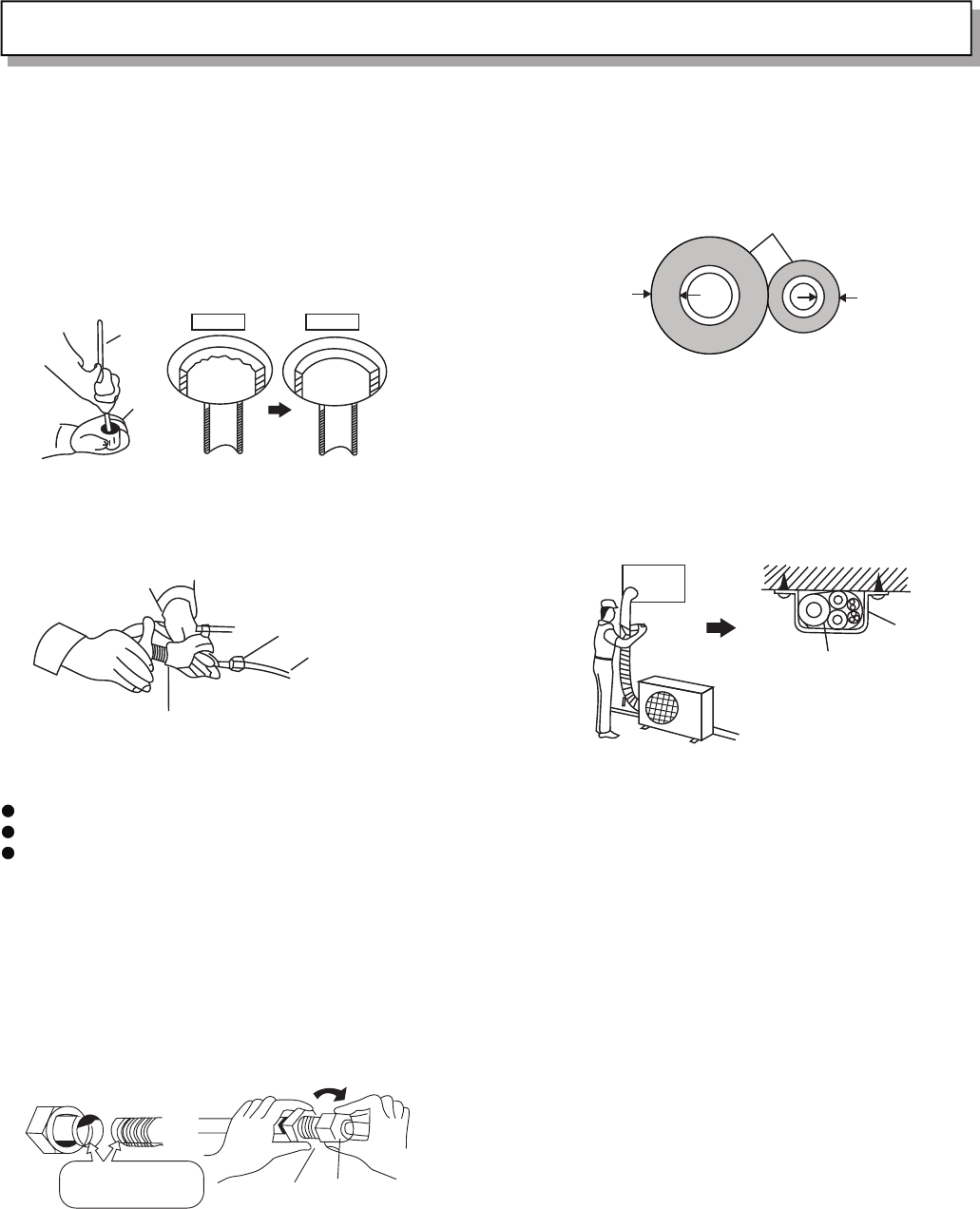

5.REFRIGERANT TUBE

5.1 Flaring the tube

(1) Cut the tube with a tube cutter to the desired length

(30.50cm is recommended)

(2) Smooth the edge of the copper tube with a reamer or a file.

Hold the pipe vertically with one end downward to make

sure that no copper scraps fall into the copper tube.

Figure 18a Figure 18b

(3) Put the tube flarer on the copper tube.

(4) Flare the copper tube ( Figure 19)

Figure 19

Note: The flared tube should have:

Smooth internal surface

Smooth edges

Consistent length of the tapered surface

5.2 Connection of the tubes

(1) The sealing tube must be used to prevent dust or water

from getting into the tube.

(2) Before connecting the tube, apply some refrigerant oil on

the surface of the flared tube and connections to prevent

air leakage.( Figure 20)

(3) Align the connecting tube and the flared tube, and then

turn the tapered nut to connect tightly. (Figure 21)

(4) Fasten the nuts with a spanner.

Copper

tube

Before

After

Reamer

Application

of refrigerant oil

Flared tube

Connecting

tube

5.3 Heat insulation of the refrigerant tube

All refrigerant tubes must be insulated heat with at least 8mm

thick insulation materials. (Figure 22)

5.4 Wrapping the tubes

(1) Tie the two refrigeration tubes (including electrical wire if

permitted as regulated), water drainage hose with white

tape.

(2) Wrap half of the tubes outside the room starting from the

end. (Figure 23)

(3) Fix the wrapped tubes on the wall in clips with a space of

120cm.

Note: Do not tie the tubes too tight as this may reduce heat

insulation. Separate water drainage hose and refrigeration

tubes to prevent formation of water droplets.

5.5 Ending of installation

After completion of wrapping and insulation, seal the hole on

the wall with a suitable sealant.

5.6 Discharge gas

Place appliance A and then B. Air purging method is as

follows:

(1) Turn down the nuts on the wide and narrow tubes.

(2) Loose the nut of the flared wide tube one complete turn

with a spanner.

(3) Turn counterclockwise to open the core of the valve with a

socket screw wrench. Some gas will come out from under

the nut of the flared end of the wide tube. Tighten the nut

10 to 15 seconds later.

(4) Test for leakage at the tube connector with soapy water or

a meter. If there is no leakage, turn counterclockwise to

open the tube core of the valve on the wide tube with a

socket screw wrench.

(5) Tighten the nuts on the wide , narrow tube valves and the

valve cover.

Please contact the technical service for further information.

Appendix: Installation

26

Figure 21

Figure 22

Clip

Covering tubes with

heat insulation materials

Figure 23