12

COMMISSIONING

FILLING THE HOT WATER AND HEATING CIRCUITS

IMPORTANT

Hot water tank must be pressurised before the heating

circuit is filled.

1. Close the primary circuit filling valves (A and B)

2. Open the stop valve (1) and the draw-off tap (8). Fill the tank

with the water from the tap; close the draw-off tap (8).

3. Fill the primary (heating) circuit by opening the valves (A and B)

and pressurising to 1 bar.

ACV BG 2000-M MODULATING PREMIX GAS

BURNER

Description and operating method:

The BG 2000-M modulating burner's output is constantly adjusted to

suit the fluctuating demand for heat, thus optimising operating

efficiency.

The gas tube is covered with a metal fibre (NIT), which, in addition to

its outstanding heat-exchange properties, increases its life.

The main parts are a venturi and a valve, a unit developed specially

by Honeywell for low NOx air/gas premix burners with automatic

ignition and flame detection by ionisation.

The pressure at the gas valve outlet is equal to the air pressure in

the neck of the venturi, less the offset.The fan sucks combustion air

through the venturi, into which the gas inlet emerges.

As it passes through, the air produces a pressure differential in the

constriction of the venturi and sucks the gas into the venturi outlet.

A perfect mix of air and gas then passes through the fan to the

burner tube.

This design ensures very quiet and safe operation:

• If there is an air blockage, the pressure differential in the venturi

falls, the gas flow diminshes, the flame goes out and the gas

valve closes: the burner is in safety shutdown mode.

• If there is a blockage in the chimney outlet, the air flow diminishes,

and the same reactions as those described above cause the

burner to shut down in safety mode.

• The BG 2000-M burner on the HeatMaster

®

201 is controlled by

an MCBA controller (Honeywell), which controls the safety of

operation of the burner and its modulation according to the

temperature.

The BG 2000-M burners are factory-set for

natural gas.

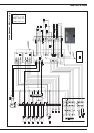

Air/gas mixture control system

12

3

4

5

2

6

7

8

9

10

11

Air

Venturi Fan

Air/gas

mixture

Gas flow adjuster

screw

Offset adjuster

screw

Gas

BURNER FEATURES

4. Open the automatic air vent located on top of the boiler.

IMPORTANT - the screw cap must be left loose to allow future

automatic venting to take place.

5. After venting the air from the system, bring the pressure up to the

static head plus 0.5 bar: 1.5 bar = 10 m and 2 bar = 15 m.

6. Check that the electrical connection and boiler room ventilation

conform to the relevant standards.

7. Switch the on/off switch to the ON position.

8. Set the temperature values

(see page 17)

.

9. Check the gas supply pressure

(see page 13)

.

10. When the burner is on, check that the flue gas discharge pipes

are completely gas tight.

11. After operating for five minutes, turn off the boiler and drain the

heating circuit again, maintaining a pressure of 1 bar.

12. Turn the appliance back on and check the combustion

(see

page 13)

.

AB