4

DESCRIPTION

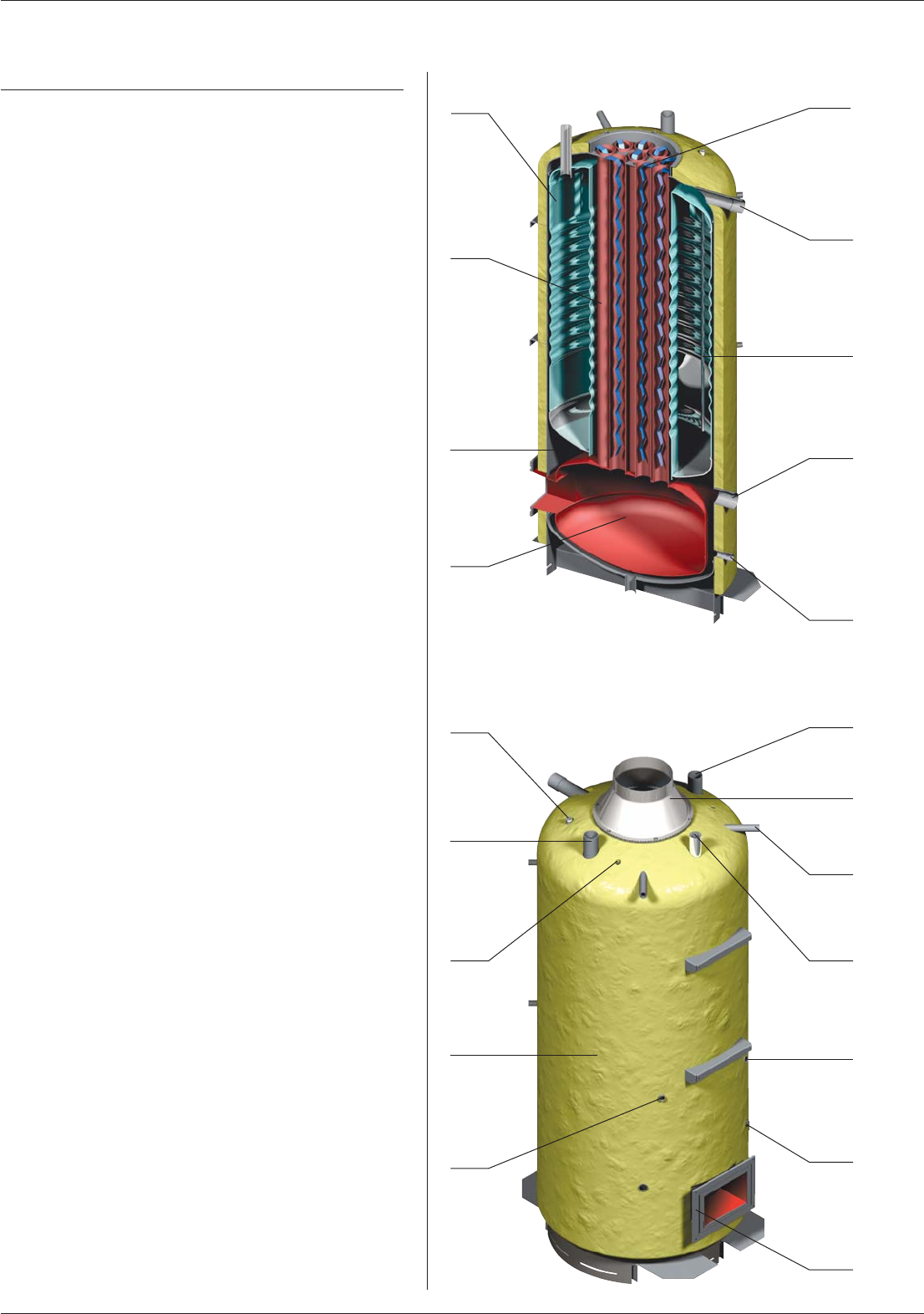

19

20

21

17

18

15

16

10

11

12

13

14

8

9

6

7

5

1

3

4

2

CONSTRUCTION FEATURES

Outer body

The outer body, containing the primary water, is made from STW 22

carbon steel.

TANK-IN-TANK heat exchanger

The ring-shaped inner tank with its large heating surface for

producing domestic hot water is built of Chrome/Nickel 18/10

stainless steel. It is corrugated over its full height by an exclusive

production process and entirely argon arc welded by the TIG

(Tungsten Inert Gas) method.

Combustion gas circuit

The combustion gas circuit is paint-protected and comprises:

• Flue pipes

Depending on output, HeatMaster

®

200 models contain

several steel flue pipes with an internal diameter of 64 mm.

Each pipe is fitted with a baffle of special steel designed to

improve heat exchange and reduce flue gas temperature.

• Combustion chamber

The combustion chamber on HeatMaster

®

models is entirely

water cooled.

Insulation

The boiler body is fully insulated by rigid polyurethane foam with a

high thermal insulation coefficient, sprayed on without the use of

CFCs.

Casing

The boiler is covered by a steel jacket which has been scoured and

phosphated before being stove enamelled at 220°C.

Burner

The HM 200 F model is always delivered with a “RIELLO” RG4S 396

T1 fuel oil burner.

Legend

1. “Tank-in-Tank” type storage exchanger

2. Flue ways

3. Primary circuit

4. Combustion chamber

5. Turbulators

6. Heating outlet

7. Stainless steel pocket

8. Heating return

9. Boiler drain cock

10. Hot water priority thermostat bulb

11. Cold water inlet

12. Bulbs of the thermal reset high-limit 95°C thermostat and the

manual reset high-limit 103°C thermostat

13. Insulation

14. Low-water-level pressure switch

15. Hot water outlet

16. Chimney reducer

17. Steam trap

18. T&P valve

(optional)

19. Thermostat-pressure gauge bulb

20. 60 - 90°C control thermostat bulb

21. Flange of the burner chamber plate