11

MAINTENANCECOMMISSIONING

12

3

4

5

2

6

7

8

9

10

11

I

O

4. Open the automatic air vent located on top of the boiler.

Important: You must not excessively tighten the threaded plug to

allow automatic bleeding.

5. After venting the air from the system, bring the pressure up to the

static head plus 0.5 bar: 1.5 bar = 10m and 2 bar = 15 m.

6. Check the electrical connection and the ventilation in the boiler

room.

7. Move the main switch to “ON”.

8. Set the thermostat to the desired temperature.

9. When the burner is on, check that the flue-gas discharge pipes

are completely gas tight.

10. After operating for five minutes, turn off the boiler and drain the

heating circuit again, maintaining a pressure of 1 bar.

11. Turn the appliance back on and check the combustion

(see table

page 5).

AB

SERVICE INTERVALS

ACV recommends that boilers should be serviced at least once a year.

The burner must be serviced and tested by a competent engineer.

In the event of heavy use of the boiler, it may require servicing on a

more regular basis than once a year. In this case, contact ACV for

advice.

SERVICING THE BOILER

1. Set the main switch on the control panel to OFF and cut the

outside power supply.

2. Close the valve supplying gas to the boiler.

Vertical flue-gas outlet reducer

3. Take down and remove the flue lining to release the top of the

boiler.

4. Loosen the nuts and remove the chimney reducer.

5. Take out the turbulators from the flue ways to clean them.

6. Dismantle the chamber plate and remove the burner.

7. Brush the flue ways.

8. Clean the combustion chamber and the burner.

9. Replace the turbulators, the chimney reducer, and the flue lining;

check that the seal on the chimney reducer is in good condition.

Replace the seal if necessary.

Horizontal flue-gas outlet reducer

3. Loosen the nuts and remove the chimney reducer.

5. Take out the turbulators from the flue ways to clean them.

6. Dismantle the chamber plate and remove the boiler.

7. Brush the flue ways.

8. Clean the combustion chamber and the burner.

9. Replace the turbulators, the chimney reducer, and the flue lining;

check that the seal between the chimney reducer and the

chimney is in good condition. Replace the seal if necessary.

SERVICING THE SAFETY DEVICES

- Check that all thermostats and safety devices are working properly.

- Test the safety valves on the central heating and hot water circuits.

SERVICING THE BURNER

- Check that the insulation and the seal on the chamber plate are in

good condition; replace them if necessary.

- Check and clean the burner.

- Check that the safety devices are in good working order.

- Check the combustion

(CO2, CO)

and record the values and any

other comments on page 15 of the service record.

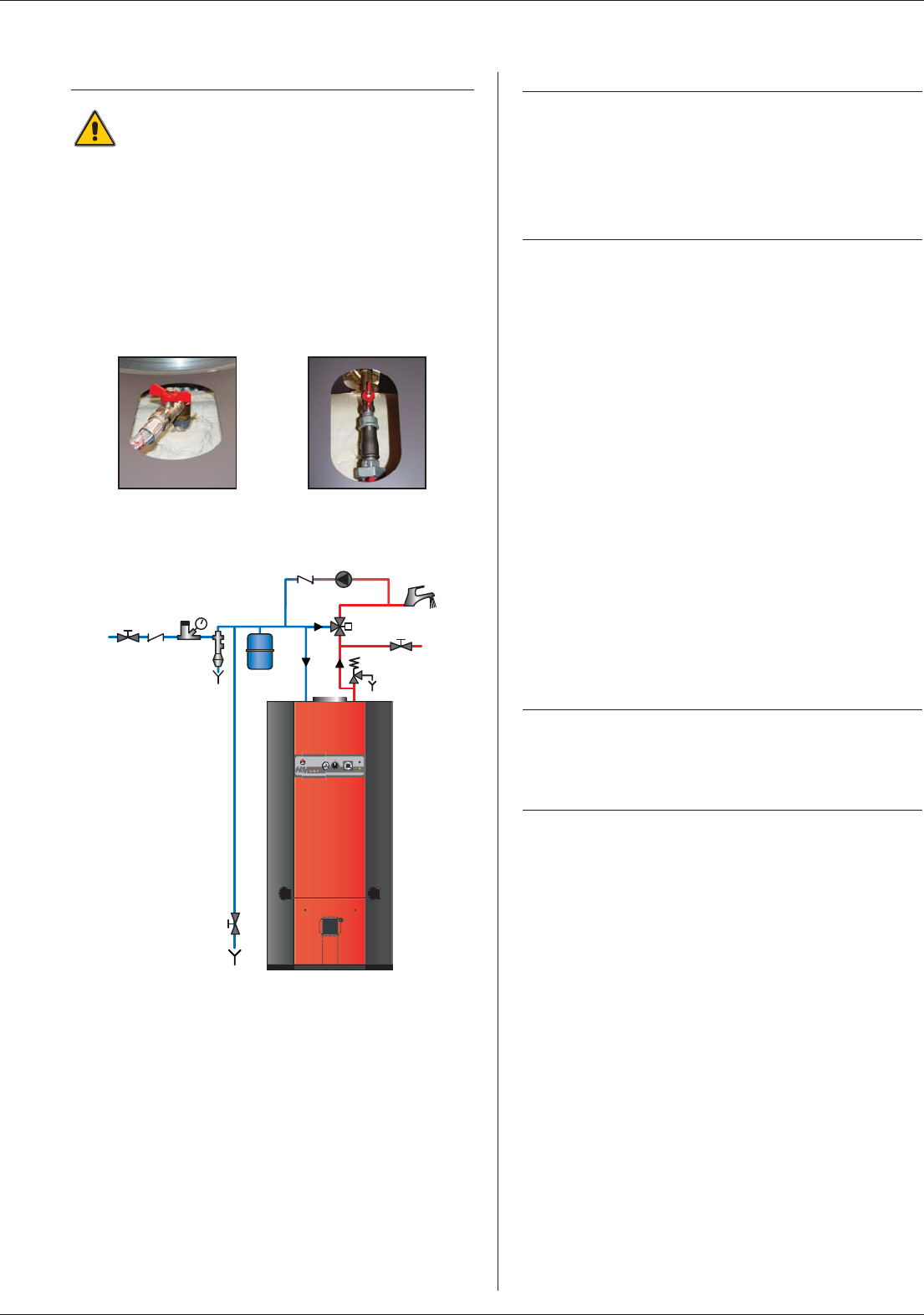

FILLING THE HOT WATER AND HEATING CIRCUITS

IMPORTANT

Hot water tank must be pressurised before the

heating circuit is filled.

1. Close the fill valves for the heating circuit (A and B).

2. Open the stop valve (1) and draw-off tap (8).

Fill the tank with the water from the tap; close the draw-off

tap (8).

3. Fill the primary heating circuit by opening the fill valves

(A and B), taking care not to exceed 1 bar of pressure.