– 5 –

Inlet gas pressure to the appliance must not exceed the

gas pressures marked on the rating plate; 7” W.C. for

natural gas, 14” W.C. for L.P. gas. The minimum supply

pressure for the purpose of input adjustment is 1” above

manifold pressure.

The appliance and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressure in

excess of 1/2 psig (3.5 kPa).

The appliance must be isolated from the gas supply

piping system by closing its individual manual shutoff

valve during any pressure testing of the gas supply piping

system at test pressures equal to, or less than 1/2 psig

(3.5 kPa).

The appliance and its gas connection must be leak tested

before placing the appliance in operation. It is important

to have a readily accessible manual shutoff valve in the

gas line supplying the heat close to the heater. A drip leg

must be installed ahead of the gas control valve to help

trap sediment and foreign material.

A ground-joint union must be installed ahead of the gas

valve to permit easy removal of the unit. All leak testing

must be done with a soapy water solution.

NEVER USE A MATCH OR OPEN FLAME TO TEST FOR

GAS LEAKS. A FIRE OR EXPLOSION COULD RESULT.

WATER PIPING

Pipes and fittings should be installed in compliance with

the installation drawing. Check for dip tube in cold water

fitting before connection of hot and cold water lines. Show

where the water shut-off valve for the water heater is

installed so that the owner knows where and how to shut

the water off. It is recommended that such a valve be

located in close proximity to the cold water inlet of the

water heater.

Connect the cold water supply (3/4 NPT) to the fitting

marked “COLD”, the hot water outlet (3/4 NPT) to the

fitting marked “HOT”. Do not apply heat to either of these

fittings as they contain a nonmetallic tube. When making

these connections, always use a good grade of pipe joint

compound and be certain that all fittings are tight. See

installation drawing (FIGURE 2).

After piping has been installed, allow tank to fill with water

and check connections for leaks. To insure complete

filling of the tank, allow air to exit by opening the nearest

hot water faucet until a constant flow of water is obtained.

TEMPERATURE & PRESSURE RELIEF VALVE

For protection against excessive pressure and/or

temperatures, a temperature and pressure relief valve

has been installed in the water heater.

ANY REPLACEMENT VALVE MUST NOT EXCEED

THE TEMPERATURE AND PRESSURE RATING.

FAILURE TO INSTALL AND MAINTAIN A NEW,

PROPERLY LISTED TEMPERATURE AND PRESSURE

RELIEF VALVE WILL RELEASE THE

MANUFACTURER FROM ANY CLAIMS WHICH MIGHT

RESULT FROM EXCESSIVE TEMPERATURE OR

WATER PRESSURE.

GAS CONNECTIONS

Install the gas piping as indicated in Figure 2. Use only

new pipe and fittings with sound, clean-cut pipe threads.

Sealing compound must conform to the applicable code

for pipe sealing compound approved for use with natural

gas and propane. Use gas piping of adequate sizing to

ensure full gas input. All piping must comply with all local

codes. In the absence of local codes, piping must comply

with the rules stated by the applicable National Fuel Gas

Codes. The final connection to the gas control valve is

made using 1/2” N.P.T. pipe.

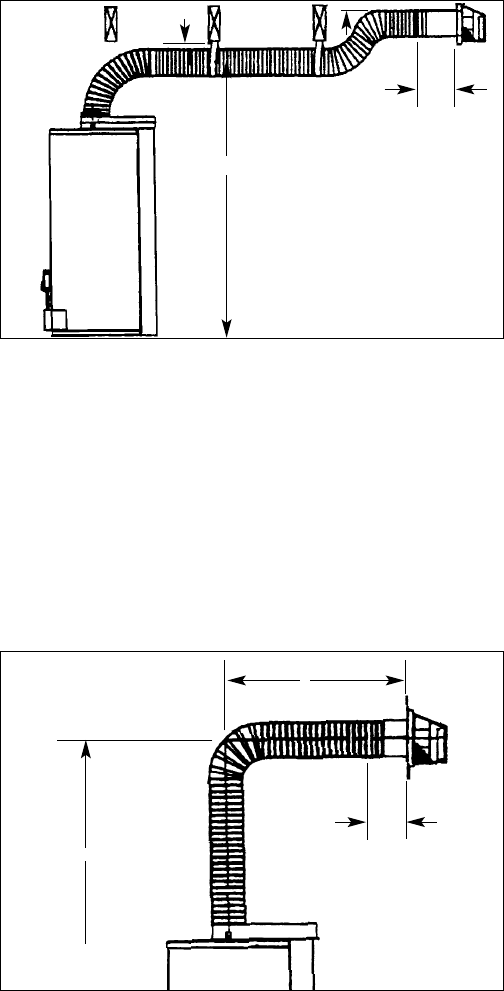

WALL

10”

(REF)

Figure 3 L - CONDITION 2

Where floor joists impede venting, a rise to complete the

vent termination is possible. All installations require 1”

clearance to combustibles.

Note:

A. The maximum horizontal vent pipe length of 90” minus

wall thickness should be considered when installing

an offset vent arrangement.

B. Do not Combine condition (3K) with condition (3L)

in the same installation.

High Rise Vent Pipe Arrangement

Figure 3 M

When the height H (From vent terminal center line to

bottom of heater) is over 90”, it is a high rise vent pipe

arrangement. The minimum distance “D” from the center

of the water heater to the outside wall surface is 22”, and

the maximum height of “H” is 12 feet.

68 MINIMUM

H

TO BOTTOM

OF HEATER

D

WALL THICKNESS

>1”

>1”

10”

(REF)