SLOPE

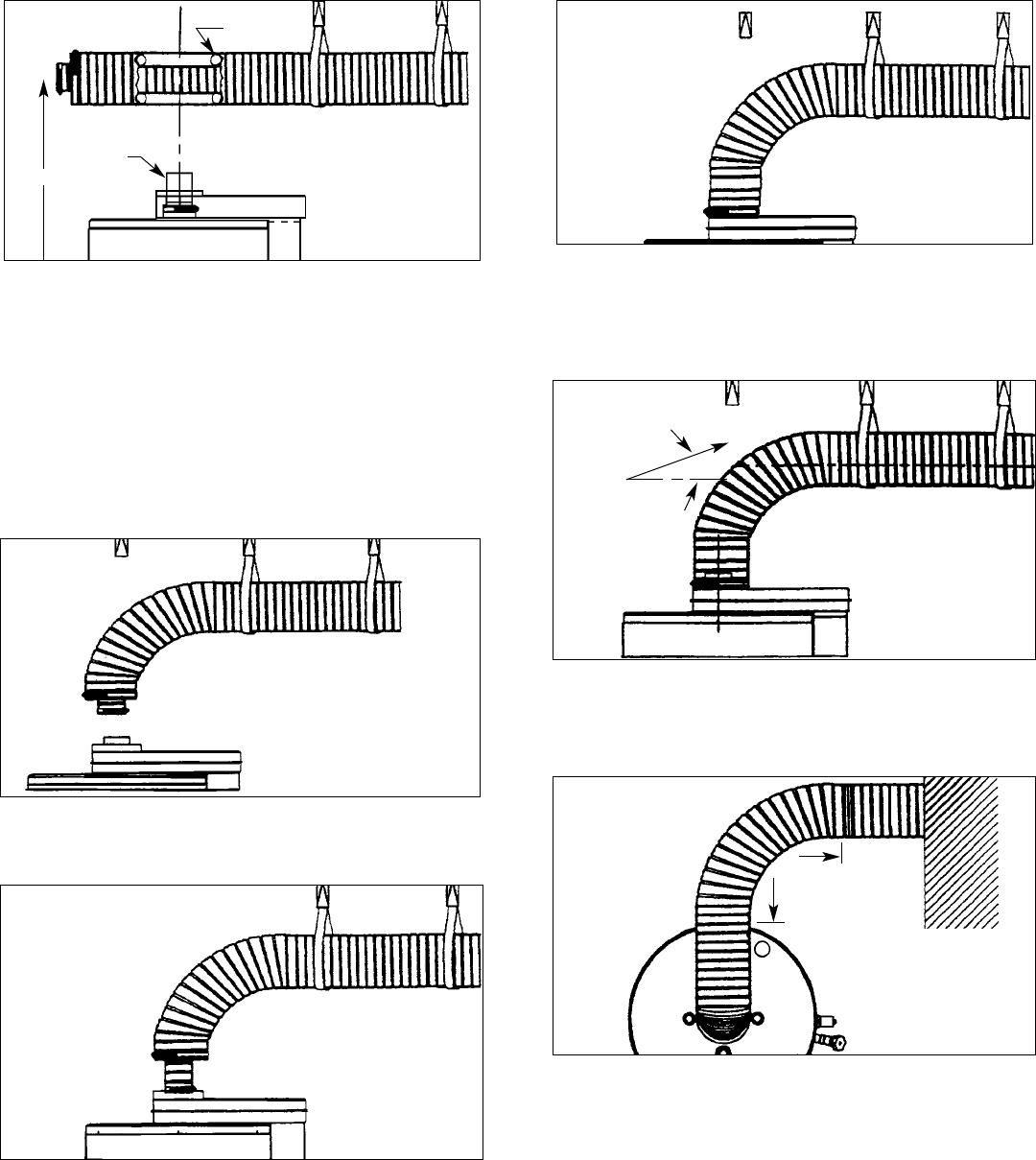

Figure 3 J

Check the vent pipe’s level or slope again, and adjust if

required.

– 4 –

Figure 3 F

Bend the 3 1/8” and 6” corrugated pipe all together

toward the water heater’s flue connection.

Figure 3 G

Pull and connect the 3 1/8” corrugated pipe to the water

heater’s flue tube reducer with hi-temp red silicone and gear

clamp. Make sure this connection is tight and leak proof.

*The sealant between 3 1/8” corrugated pipe and water

heater’s flue tube reducer must be hi-temp red silicone

or other material suitable for 600°F continuous service.

Figure 3 H

Apply silicone around 6” collar on air manifold box. Pull

corrugated vent tube all the way on to collar and secure

with one sheet metal screw (approx. 3/4”) up from edge

of vent tube. Pull gear clamp past screw and tighten.

Figure 3 E - Pull the 3 1/8” and 6” Corrugated Pipe

Toward the Water Heater Individually.

1. Pull the 3 1/8” corrugated pipe toward the water

heater and leave some length over the water

heater’s center for bending.

2. Pull the 6” corrugated pipe toward the water heater

and leave it 1” shorter than 3 1/8” pipe.

3. Make sure there are two springs evenly spaced at

the bend in the pipe.

4. Use metal hangers to keep vent pipe level or with a

slope upward from the heater to terminal.

REDUCER

TOP VIEW

90°

MAXIMUM

BEND

Figure 3 K - CONDITION 1

Where a straight vent pipe arrangement is impossible, a

horizontal 90 degree maximum bend can be made. Use

the water heater casing outer diameter as a template to

form the corrugated pipe.

H

SPRING

Offset vent pipe Arrangement