– 3 –

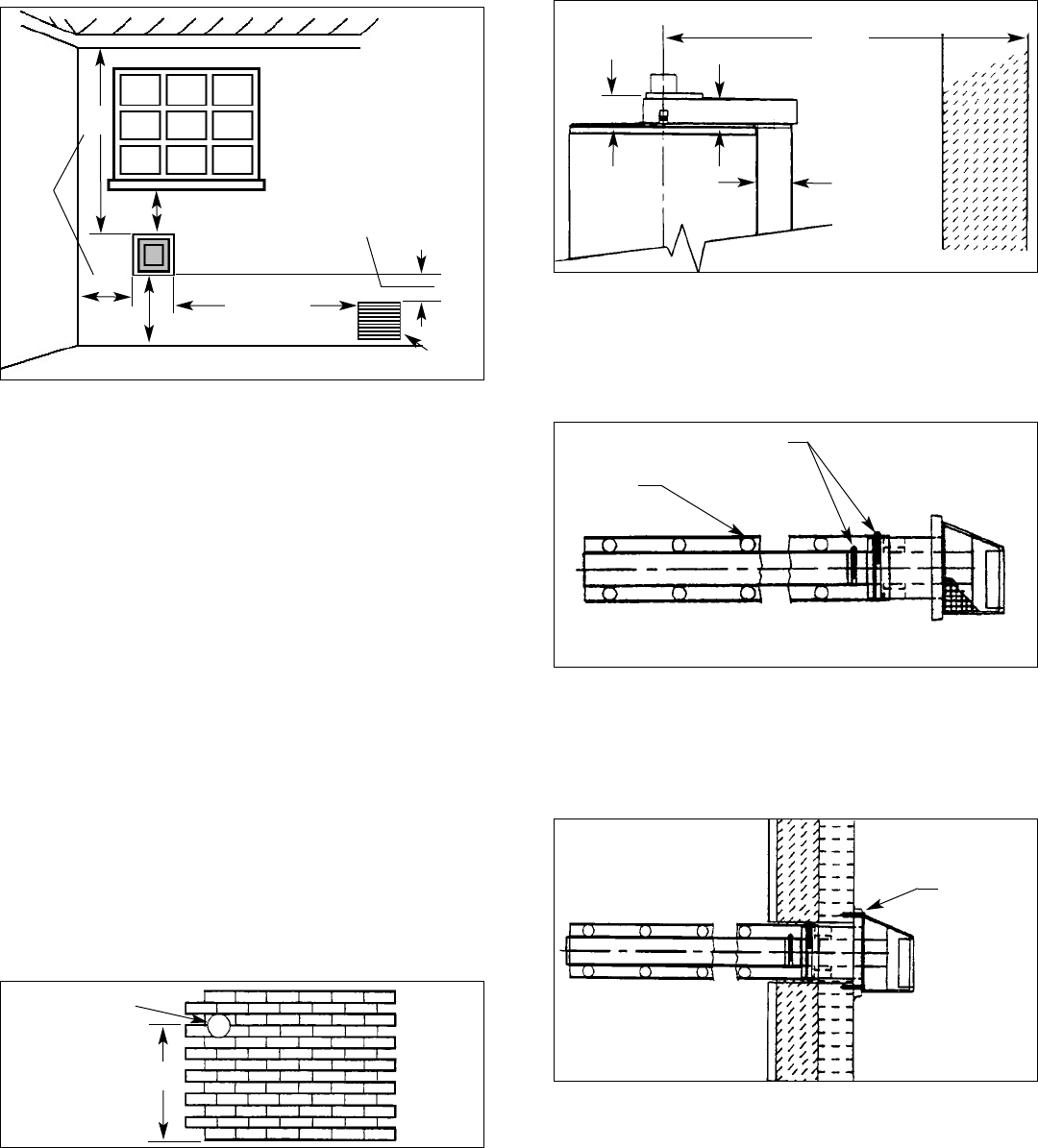

Figure 3 - Vent Location Limitations

For a second or more direct vent unit, the distance

between vent terminals must have a minimum of 1 foot.

INSPECT SHIPMENT –– There may be hidden damage

caused by transit. Check to be certain all parts of the

venting system, as shown in Figures 3A through 3M, are

present. Inspect the upper and lower air inlet boxes, rear

air tube and all parts of the venting system.

CAUTION

If there are any damaged parts, DO NOT install this water

heater. Report any shortage to your distributor or damage

to your carrier.

Note: The four fasteners that are required to secure the

vent terminal to the exterior wall are not provided. These

should be screw type (not nails) chosen for the type of

construction and obtained locally.

CAUTION

Cut edges of corrugated (flex) pipe are extremely sharp.

Wear gloves when handling.

VENT CONNECTIONS - After the location for the vent

terminal has been selected as outlined in Figure 3, use

the following illustrations for installation:

7” DIAMETER

Figure 3 A - Locating Clearance Hole for Vent.

Cut a clearance hole, approximately 7 inches in diameter,

through the exterior wall for the vent assembly. The

minimum height should not be less than 68” from the hole

center to bottom of water heater. The maximum height

recommended is 90” or in compliance with figure 3M.

*Where the wall is combustible and the wall thickness is

over 14”, 1 inch clearance to combustible materials around

the terminal pipe is needed. The first 14” is zero clearance.

MIN.

68”

Vent Terminal must be located at

least 12” from Windows, Doors,

or any other Opening through

which flue gases could enter the

building.

Any Forced Air Inlet

into the building

Vent Terminal must be located at least 18”

from any overhang or building corner or

other irregularity.

12” Min. above grade. Higher

in Areas of Heavy Snowfall

Within 10 feet

36”

Min.

12” Min.

Vent terminal must be

located at least 36” above

any Forced Air Inlet into the

building within 10 feet of

the Vent Terminal

18”

Min.

18”

Min.

Figure 3 C - Vent Assembly.

The vent pipe and terminal are assembled by the

manufacturer as shown in figure 3C. There are springs

fastened inside the corrugated pipe. When the vent pipes

are pulled to a required length, the distances between the

springs will still be equally spaced.

Figure 3 B - Moving Water Heater To Its Final

Installed Location.

Move the water heater to its final installed location. Make

certain clearances from combustible material are

observed. The maximum distance from center of water

heater to outside wall should not be longer than 90”.

MAX. 90”

3”

4”

4”

WALL

CLAMP

SPRING

Specially For Direct Vent Water Heater:

Make certain to observe the vent location limitations

complying with the CAN/CGA-B149 Installation Code or

ANSI Z223.1 National Fuel Gas code and/or local codes.

There are some important issues shown in Figure 3.

BOTTOM OF HEATER

Figure 3 D - Securing Vent Termination Assembly To

The Exterior Wall.

Introduce the 6” pipe through the clearance hole from

exterior wall then secure the vent terminal to the exterior

wall with 4 screw anchors appropriate for the type of

wall construction. Caulk the junction of the vent terminal

base plate and the exterior wall with exterior type

silicone sealant.

SEALANT