88

Fan and Heater

SELF-OPERATED MODULATING VALVES

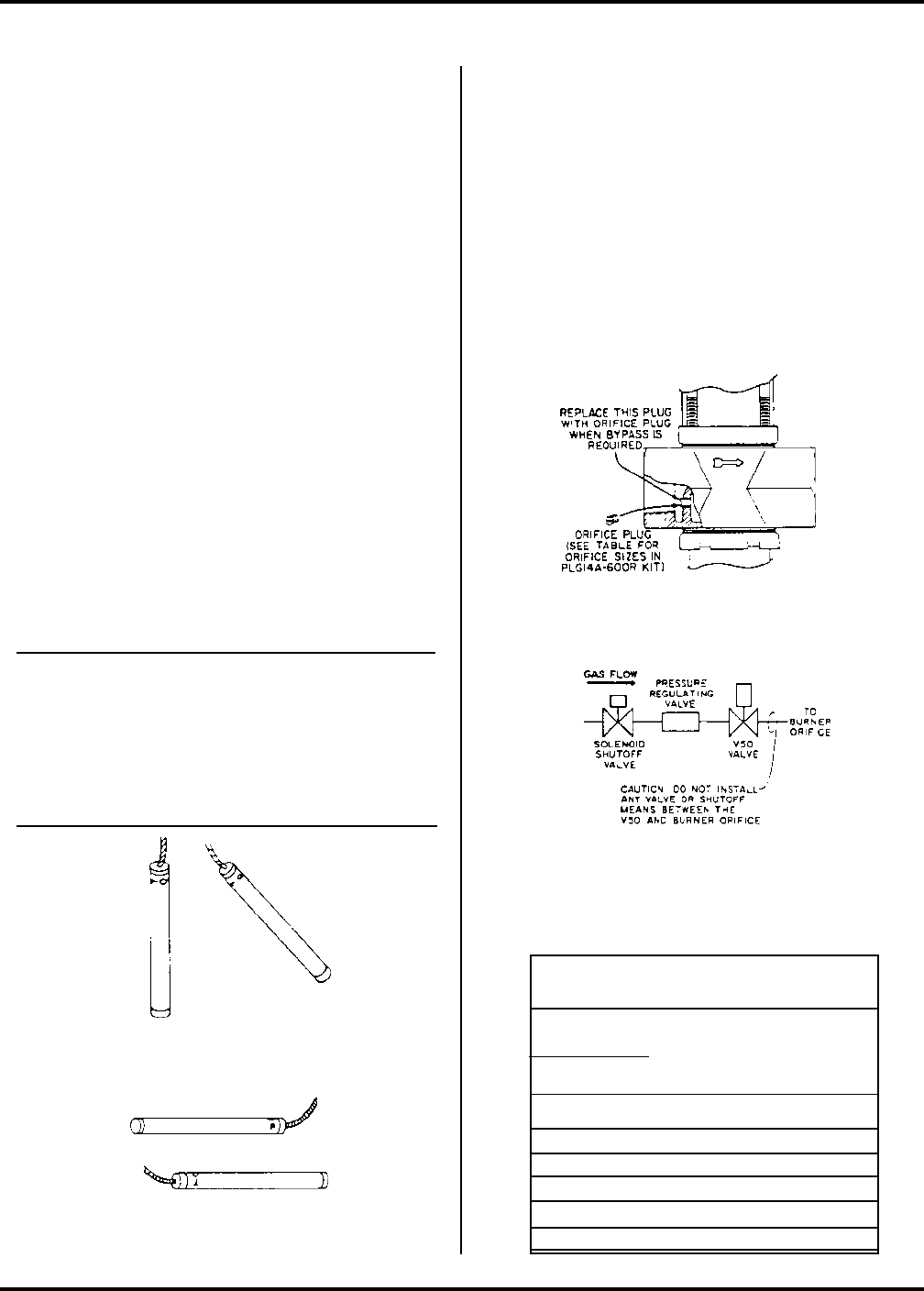

Orifice Sizes in Kit

Number PLG14A-600R

Orifice Size Color

In. mm Code

.040 1.02 Red

.062 1.57 Yellow

.078 1.98 Green

.093 2.36 Blue

.125 3.18 Aluminum

Solid Plug Brass

If the installation requires that the bulb be in a

horizontal position, it is very importanat to be sure

that the word "TOP" appears at the top or upper-

most surface of the bulb. (see Figure 4).

CAUTION: Do not kink or sharply bend the

capillary tubing. Coil and secure excess capillary

if installed where subjectd to vibration, allowing

some slack in capillary to avoid "violin string"

vibrations. Do not allow capillary to rub surfaces

where friction can damage the tubing.

Installation and Operation Instructions,

continued

Be sure the valve is installed so the gas flows

through the body in the proper direction as indi-

cated by the arrow on the body.

On direct or indirect fired vaporizer systems in

which hot LP gas is flowing through the valve,

install the valve with the bellows pointing down.

This allows the temperature sensing element to

perform properly. In vapor withdrawal systems,

the gas flowing through the valve is cooler than

the sensing bulb and valve is cooler thatn the

sensing bulb and valve mounting position is not as

important.

The temperature sensing bulb should be installed

so the capillary end of the bulb is always higher

than the plugged and of the bulb (see figure 3.)

Bypass Orifice Selection

These valves have a threaded hole in the internal

web of the valve for an internal bypass. ( See

figure 5) They are normally supplied with a solid

plug installed in this hole for complete shutoff.

Five drilled orifice fittings are supplied with each

valve for field installation, if bypass is needed. The

bypass orifice is ued to maintain a minimum flame

which will burn even when the close-off point has

been reached. When bypass is required, remove

the solid plug and replace with the proper orifice

plug. See selection table.

Figure 3-Capillary-end of bulb higher than plugged-end

of temperature bulb.

Figure 4-Horizontal bulb mounting with "TOP" at top

or uppermost surface of bulb.

Figure 6-Typical piping for the V50 Valve

Figure 5-Cutaway view showing location of orifice

plug