Start Up and Adjust Pump

14 312376L

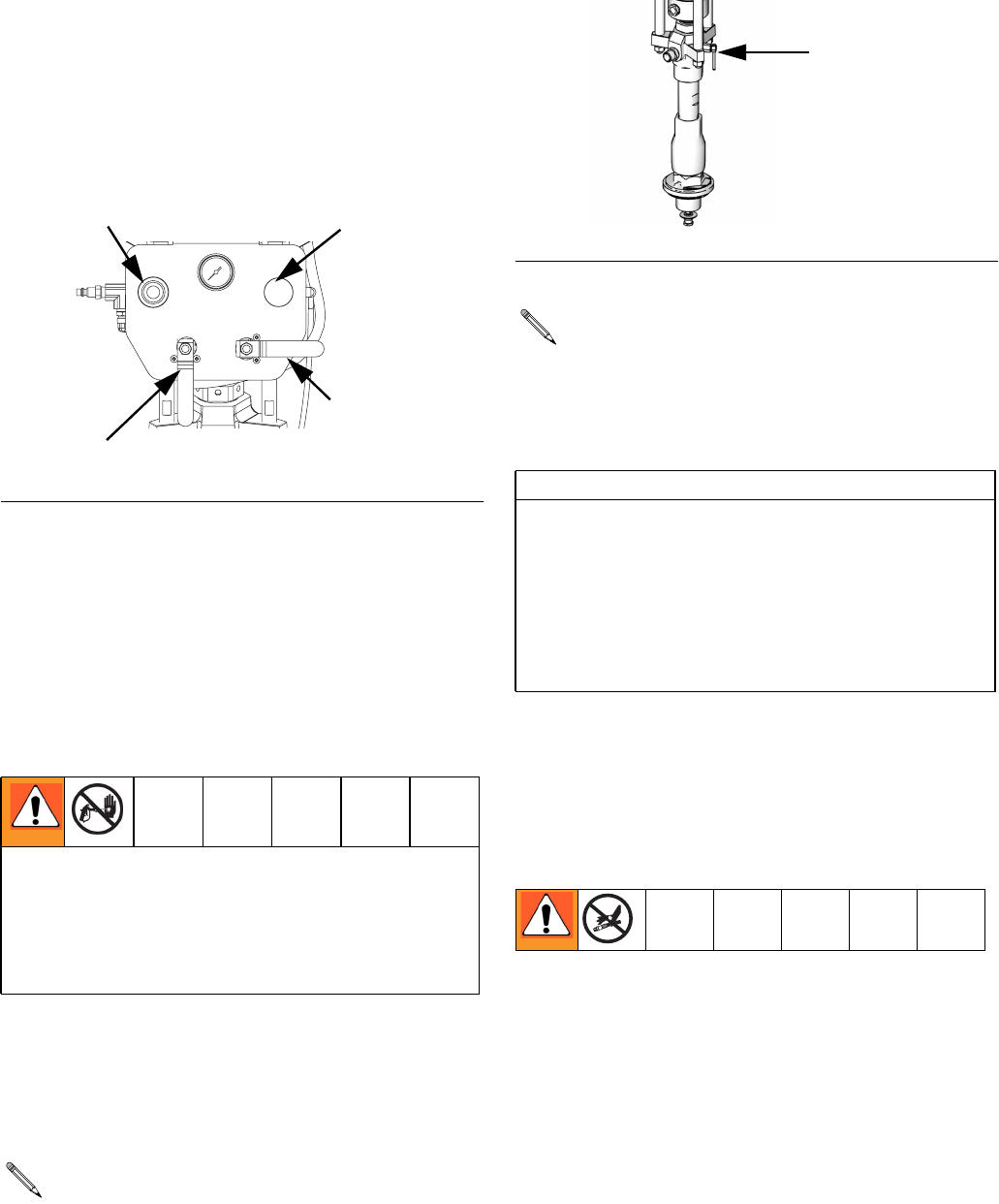

4. For L20c Air Controls:

a. Close elevator director valve. The ram will

slowly drop.

b. If necessary, press blowoff push button to pause

elevator descent.

5. Reduce the air motor regulator pressure and open

the air motor valve.

6. Adjust air motor regulator until the pump starts.

7. Cycle the pump slowly until all air is pushed out and

the pump and hoses are fully primed.

8. Release the gun/valve trigger and lock the trigger

safety. The pump should stall against pressure.

9. If the pump fails to prime properly, open the pump

bleed valve (P) slightly. Use the bleed hole, on the

underside of the valve, as a priming valve until the

fluid appears at the hole. Close the plug.

10. With the pump and lines primed, and with adequate

air pressure and volume supplied, the pump will

start and stop as you open and close the gun/valve.

In a circulating system, the pump will speed up or

slow down on demand, until the air supply is shut

off.

11. Use the air motor regulator (see FIG. 10) to control

the pump speed and the fluid pressure. Always use

the lowest air pressure necessary to get the desired

results. Higher pressures cause premature tip/noz-

zle and pump wear.

FIG. 10: L20c Air Controls

To reduce the risk of fluid injection, do not use your

hand or fingers to cover the bleed hole on the under-

side of the bleed valve body (P) when priming the

pump. Use the handle or a crescent wrench to open

and close the bleed plug. Keep your hands away from

the bleed hole.

Always use lowest possible fluid pressure to bleed

air out of pump.

Air Motor Regulator

Elevator Director

Valve

Air Motor Valve

r_257302_312376_2e

Blowoff Push Button

F

IG. 11

When changing fluid containers with the hose and

gun/valve already primed, open the pump bleed

valve (P), to help prime the pump and vent air

before it enters the hose. Close the valve when all

air is eliminated.

CAUTION

Do not allow the pump to run dry. It will quickly accel-

erate to a high speed, causing damage. If your pump

is running too fast, stop it immediately and check the

fluid supply. If the container is empty and air has been

pumped into the lines, refill the container and prime

the pump and the lines, or flush and leave it filled with

a compatible solvent. Eliminate all air from the fluid

system.

ti10420a

P