Setup

332317C 19

Loading Grease

To ensure optimal performance from the G1:

• Only use NLGI #000 - #2 greases appropriate for

your application, automatic dispensing, and the

equipment’s operating temperature. Consult with

machine and lube manufacturer for details.

• The reservoir can be filled using a hand operated

pump, pneumatic pump or electric transfer pump.

• Do not overfill (F

IG. 8).

• Do not operate G1 without reservoir attached.

Models without a follower plate:

1. Connect fill hose to inlet fitting (37) (FIG. 7).

2. For higher viscosity fluids, press the

manual run button to start the pump

during fill to rotate the stirring paddle

and prevent air pockets from forming in

grease.

3. Fill reservoir with NLGI grease to max fill line.

NOTE: Vent port, located in rear of reservoir, should not

be used as an overfill port/indicator.

4. Remove fill hose.

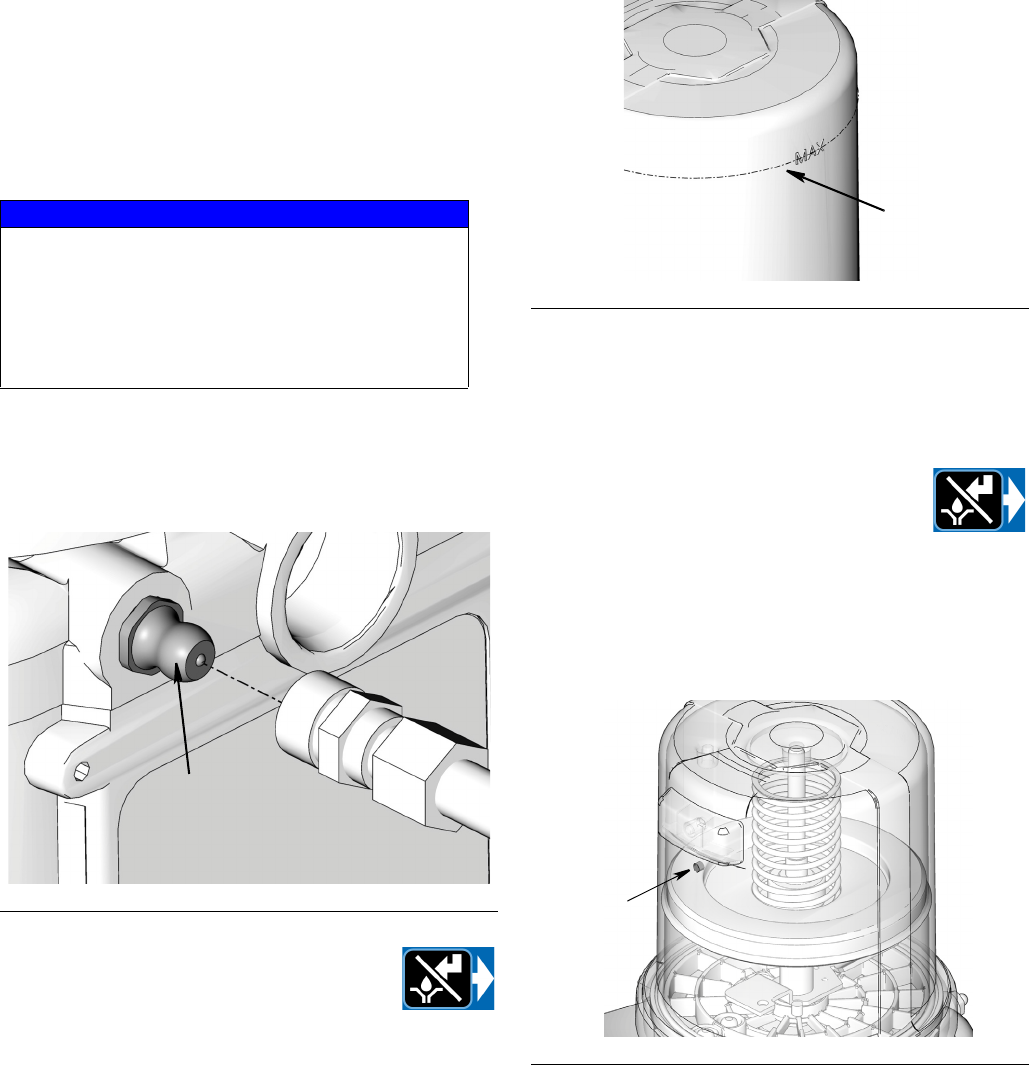

Models with a follower plate:

1. Connect fill hose to inlet fitting (FIG. 7).

2. For higher viscosity fluids, press the

manual run button to start the pump

during fill to rotate the stirring paddle

and prevent air pockets from forming in

grease.

3. Fill reservoir with grease until seal of follower plate

breaches the vent hole (F

IG. 9) and the majority of

air is expelled from the reservoir.

NOTE: Vent port, located in rear of reservoir, should not

be used as an overfill port/indicator.

4. Remove fill hose.

NOTICE

• Always clean fitting (37) with a clean dry cloth

prior to filling reservoir. Dirt and/or debris can

damage pump and/or lubrication system.

• Care must be used when filling the reservoir

using a pneumatic or electric transfer pump to

not pressurize and break the reservoir.

F

IG. 7

37

FIG. 8

F

IG. 9

max fill line

vent hole