6 308652

Installation

Air Lines

WARNING

Bleed-Type Master Air Valve and Fluid Drain

Valve

A bleed-type master air valve and a fluid drain

valve are required on your system.

The bleed-type master air valve relieves air

trapped between itself and the pump. Trapped air

can cause the pump to cycle unexpectedly, which

could result in serious bodily injury, including

splashing in the eyes, injury from moving parts, or

contamination from hazardous fluids.

The fluid drain valve reduces the risk of serious

bodily injury, including splashing in the eyes or on

the skin, or contamination from hazardous fluids.

Install the fluid drain valve close to the pump’s

fluid outlet to relieve pressure in the hose if the

hose becomes plugged.

1. Mount the air line accessories on the wall or on a

bracket. Be sure the air line supplying the acces-

sories is grounded.

a. The pump speed can be controlled in one of

two ways: To control it on the air side, install

an air regulator. To control it on the fluid side,

install a fluid valve near the outlet.

b. Install a bleed-type master air valve down-

stream from the air regulator, and use it to re-

lieve trapped air. See the Bleed-Type Master

Air Valve and Fluid Drain Valve warning

above. Locate another bleed-type master air

valve upstream from all air line accessories,

and use it to isolate the accessories during

cleaning and repair.

c. The air line filter removes harmful dirt and

moisture from the compressed air supply.

2. Install a flexible air hose between the accessories

and the pump air inlet. Screw the air line fitting

into the air inlet.

3. Do not restrict the exhaust port. Excessive ex-

haust restriction can cause erratic pump operation.

Fluid Lines

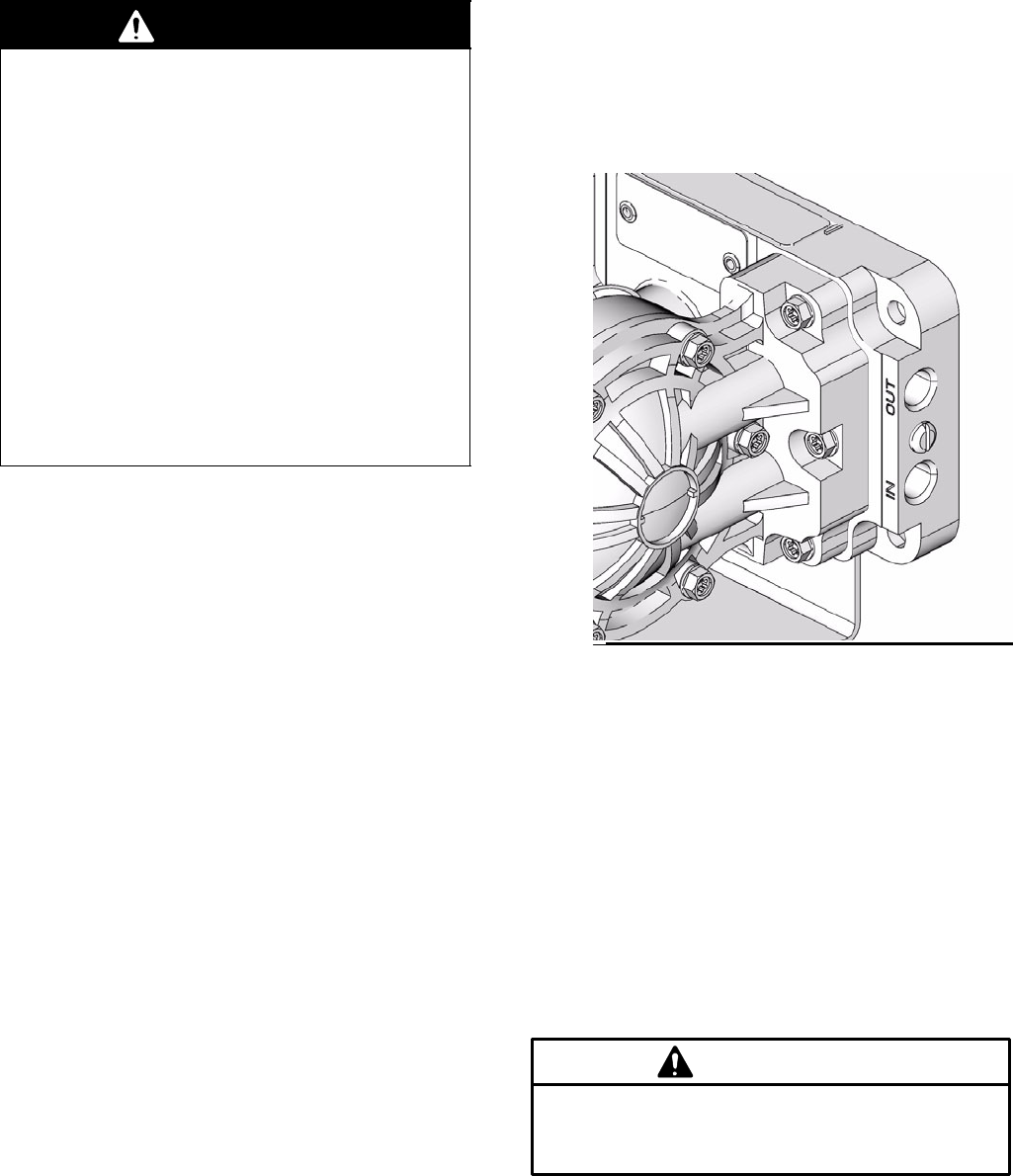

Fig. 3. On each end of the fluid manifold are a fluid IN

port and a fluid OUT port. NOTE: Make sure the fluid

OUT port on the fluid manifold is mounted up. This

will assure proper pump priming. Fluid-in and fluid-

out lines can be connected on the same end, or

opposite ends of the manifold. Plug ports that are not

used (plugs provided).

Fi

g

. 3

06179A

ti10661a

Typical Installation

The installations shown in Fig. 4 are only a guide to

help select and install a pump; they are not actual

system designs.

Typical installation includes (not supplied by Graco):

D For solenoid operation: a four-way, 5-port, 3-posi-

tion solenoid valve with 1/4-in. ports, or two 3–posi-

tion 3–way valves. Mac series 44 (4–way), or series

35 (3–way). Either way, air pressure should be

released if not cycling.

D PLC or timer. Consult your local industrial controls

distributor.

For solenoid operation, the pump must exhaust

through the solenoid. Failure to exhaust through

solenoid could cause the diaphragms to fail.

CAUTION