4 308652

Installation

Tightening Threaded Fasteners Before

First Use

Before using the pump for the first time, check and

retorque all external fasteners. See Torque Se-

quence, page 18. After the first day of operation,

retorque the fasteners. Although pump use varies, a

general guideline is to retorque fasteners every two

months.

Use a compatible thread sealant on all male threads.

Tighten all connections firmly to avoid air or fluid leaks.

CAUTION

To avoid pump damage, do not overtighten the

fittings to the pump.

Grounding

WARNING

FIRE AND EXPLOSION HAZARD

This pump must be grounded. Before

you operate the pump, ground the

system as explained below. Also read

the section FIRE AND EXPLOSION

HAZARD on page 3.

The acetal pump contains stainless steel fibers

which make the wetted parts conductive. Attaching

the ground wire to one of the grounding locations

grounds the wetted parts.

The polypropylene and PVDF pumps are not

conductive. When you pump conductive flam-

mable fluids, always ground the entire fluid system

by making sure the fluid has an electrical path to a

true earth ground. See Fig. 1. Never use a poly-

propylene or PVDF pump with non-conductive

flammable fluids as specified by your local fire

protection code. Consult your fluid supplier to

determine the conductivity or resistivity of your

fluid.

US Code (NFPA 77 Static Electricity) recommends

a conductivity greater than 50 x 10

–12

Siemans/me-

ter (mhos/meter) over your operating temperature

range to reduce the hazard of fire. Consult your

fluid supplier to determine the conductivity or

resistivity of your fluid. The resistivity must be less

than 2 x 10

12

ohm-centimeters.

To reduce the risk of static sparking, ground the pump

and all other equipment used or located in the pumping

area. Check your local electrical code for detailed

grounding instructions for your area and type of equip-

ment.

Acetal Pump Grounding Instructions

For polypropylene and PVDF pumps, see the

warning above.

Ground all of this equipment.

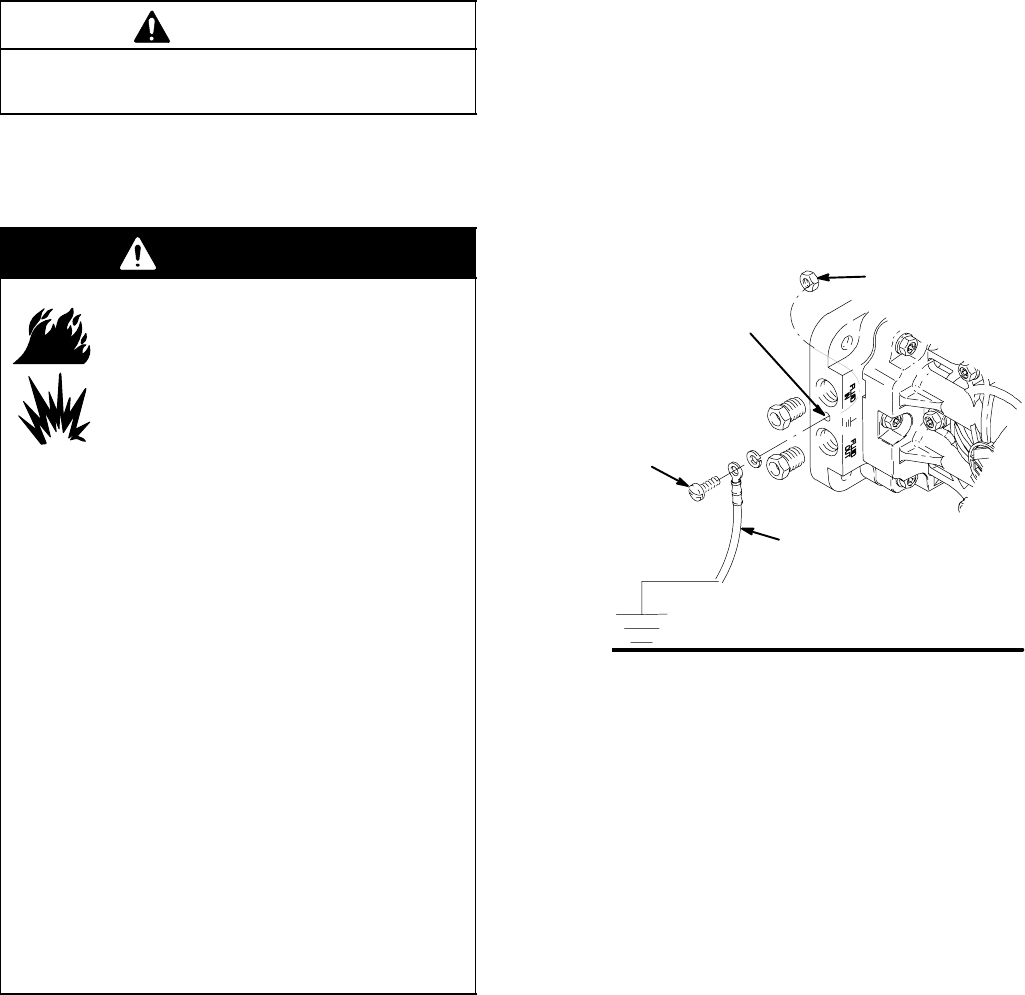

Pump: Connect a ground wire (A) and clamp, Part No.

222011. See Fig. 1. The pump grounding locations

are on the manifold between the inlet and outlet ports.

Use the nut (B) and bolt (C) that are provided with the

pump, and install as follows:

1. Place the nut in the nut catcher on the underside

of the manifold.

2. Insert the bolt through the loop end of the ground

wire.

3. Insert the bolt through the hole on the pump man-

ifold and tighten it into the nut that you positioned

in step 1.

4. Connect the clamp end of the ground wire to a

true earth ground.

Fig. 1

06179A

Fig. 1

A

C

grounding hole

B

D Air and fluid hoses: Use only grounded hoses with

a maximum of 500 ft (150 m) combined hose

length to ensure grounding continuity.

D Air compressor: Follow the manufacturer’s recom-

mendations.

D All solvent pails used when flushing: Follow the

local code. Use only grounded metal pails, which

are conductive. Do not place the pail on a non-con-

ductive surface, such as paper or cardboard, which

interrupts the grounding continuity.

D Fluid supply container: Follow the local code.