15308118

Service

Displacement Pump Service

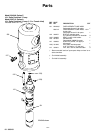

Disassembly

When disassembling the pump, lay out all removed

parts in sequence to ease reassembly. See Fig. 4.

NOTES

D Standard Repair Kit 224403 (UHMWPE/PTFE

packings) is available. For the best results, use all

the new parts in the kit. Parts included in the kit are

denoted with one asterisk, for example (2*).

D Conversion Kit 224889 is available to convert the

pump to all PTFE packings. See page 18.

D Clean all the parts thoroughly when disassembling.

Check them carefully for damage or wear, replacing

parts as needed.

1. Remove the displacement pump from the air motor

as explained on page 14.

2. Unscrew the locking ring (20) from the cylinder

(15). See Fig. 4. Remove the intake valve housing

(21).

3. Remove the o-ring (19), ball stop pin (17), and ball

(18) from the intake valve housing (21).

4. Unscrew the cylinder (15) from the outlet housing

(5), note its orientation and carefully pull the cylin-

der off the pump. Remove the o-ring (6) from the

outlet housing.

NOTE: It is important to replace the cylinder in the

same orientation as both ends are NOT alike.

Failure to install correctly may result in failure of

pump or premature seal wear. For instructions on

how to verify correct orientation, see NOTE in step

7 on page 16.

5. Loosen the packing nut (14), then pull the dis-

placement rod (1) and connecting rod (8) out the

bottom of the outlet housing (5).

6. Secure the flats of the displacement rod (1) in a

vise. Unscrew the coupling nut (7) from the dis-

placement rod. Remove the connecting rod (8) and

attached parts.

7. Place the flats of the piston mounting stud (13) in a

vise. Loosen the jam nut (9) and unscrew the

adapter (10) from the piston mounting stud (13).

Set the connecting rod (8) aside. Remove one

cotter pin (12) and the ball stop pin (11), taking not

which set of holes it is in. Then remove the ball

(16).

8. Unscrew the piston stud (27) from the piston

mounting stud (13). Remove the piston packings

(29, 30), glands (28, 31) , shims (35), and washer

(26).

9. Remove the packing nut (14), throat packings (3,

25), and glands (2, 4) from the outlet housing (5).

10. Inspect all parts for damage. Clean all parts and

threads with a compatible solvent before reassem-

bling. Inspect the polished outer surface of the

displacement rod (1) and inner surface of the

cylinder (15) for scratches, scoring, or other dam-

age, which can cause premature packing wear and

leaking. To check, run a finger over the surface or

hold the part up to the light at an angle. Be sure

the ball seats of the piston (27) and intake valve

housing (21) are not chipped or nicked. Replace

any worn or damaged parts.