Installation

308391J 5

Installation

Pump Accessories

Suction Tube Kit: A suction tube kit is available for

siphoning from 55 gallon containers.

Intake Tube: To install, apply PTFE tape to the female

threads at the top of the tube (Q). Screw the tube tightly

into the intake housing of the stubby pump.

Low-Level Cutoff Valve: To install, screw the low-level

cutoff valve into the bottom of the pump intake tube or

the suction tube. This valve closes the pump intake

when the fluid level is low, causing the pump to stall to

avoid running all day.

Pump Outlet Drain Valve: Install a drain valve (D) close

to the pump fluid outlet assist in relieving fluid pressure

in the pump, hose, and dispense valve when the pump

is shut off.

Thermal Relief Kit: Install a Thermal Relief Kit (T) at the

pump fluid outlet.

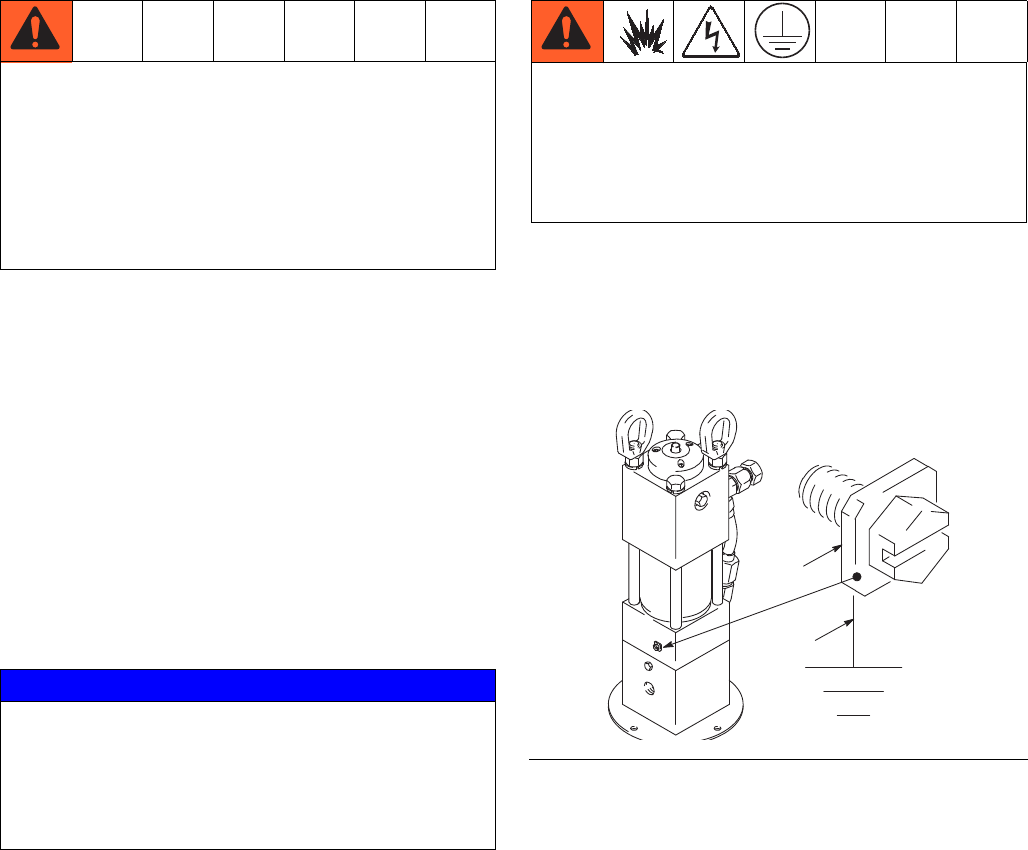

Grounding

Pump: Use a ground wire and clamp. Remove the

ground screw (Z) and insert through the eye of the ring

terminal at end of ground wire (Y). Fasten the ground

screw back onto the pump and tighten securely. Con-

nect the other end of the ground wire to a true earth

ground. (F

IG. 1)

Hydraulic and fluid hoses: Use only electrically con-

ductive hoses.

Hydraulic power supply: Follow manufacturer’s recom-

mendations.

Any pails used when flushing: Use only metal,

grounded pails when flushing. Make firm metal-to-metal

contact between the metal part of the dispense valve

and the pail. Use the lowest possible pressure.

Maximum Working Pressure of Accessories

To reduce the risk of serious injury including fluid

injection and splashing in the eyes or on the skin,

which may be caused by component ruptures, all

accessories added to the reciprocator power supply

side of the pump fluid outlet side must have at least a

1500 psi (10 MPa, 103 bar) maximum working

pressure.

NOTICE

A pump outlet drain valve is required in the system.

This valve helps relieve pressure in the

displacement pump and hose when shutting down

the system and in case of a clogged outlet hose.

Install the valve hose close the pump outlet.

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

FIG. 1

Y

Z